Mildew-proof anticorrosion processing method of bamboo and wood

A processing method and technology for wood, applied in the direction of impregnated wood, wood impregnation, wood processing appliances, etc., can solve the problems of poor durability and anti-loss performance, complicated anti-mildew treatment operations, adverse effects on people and the environment, etc., and achieve durability. It has excellent anti-bleeding performance, good anti-mildew and anti-corrosion effect, and small impact on people and the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of treatment method of bamboo wood mildew-proof and anticorrosion of the present invention:

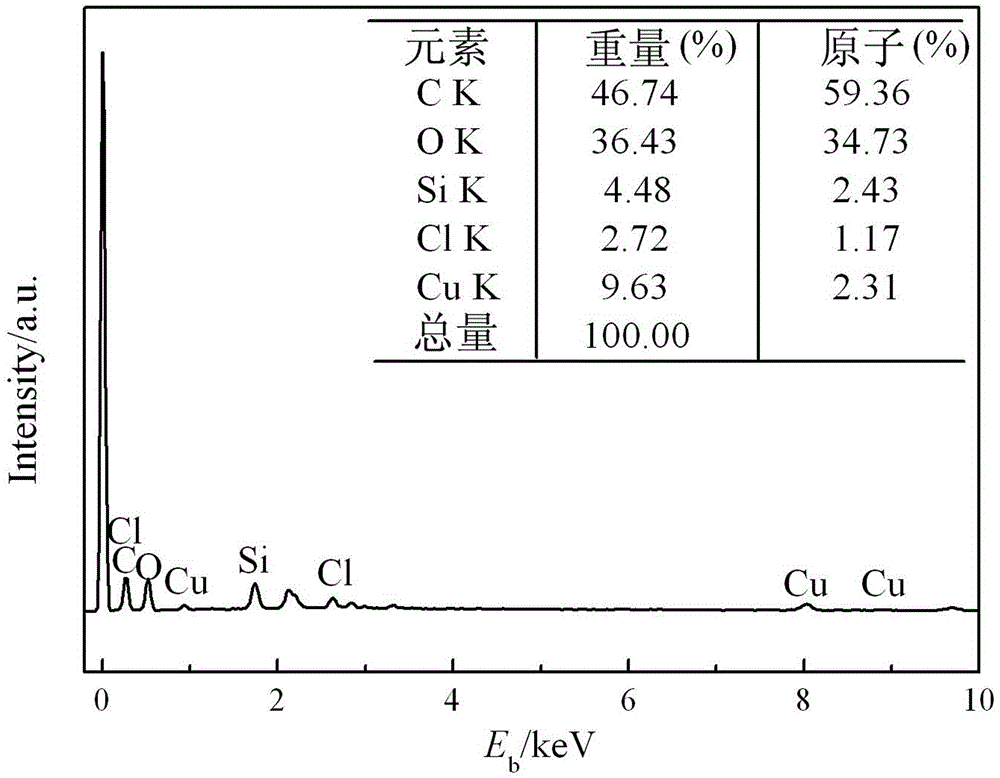

[0040] Slowly add a certain amount of ethyl orthosilicate to the aminopropyltriethoxysilane solution, while stirring the solution, and then add an appropriate amount of absolute ethanol, in which ethyl orthosilicate, aminopropyltriethoxy The volume ratio of silane and absolute ethanol is 5:0.5:2. Use dilute hydrochloric acid to adjust the pH to 3~4, stir well until the mixture has no suspended matter, and make a uniform sol. Put the bamboo wood sample into the impregnation tank, pour in the sol, press the sample with a heavy object to avoid floating of the sample, vacuumize, control the vacuum pressure at -0.06Mpa, keep the pressure for 50min, and then release the pressure. Pressurize the impregnation tank to 2MPa, keep the pressure for 80min, then release the pressure, take out the bamboo wood sample, clean the surface of the sample and empty the impregnation tank. Pu...

Embodiment 2

[0043] A kind of treatment method of bamboo wood mildew-proof and anticorrosion of the present invention:

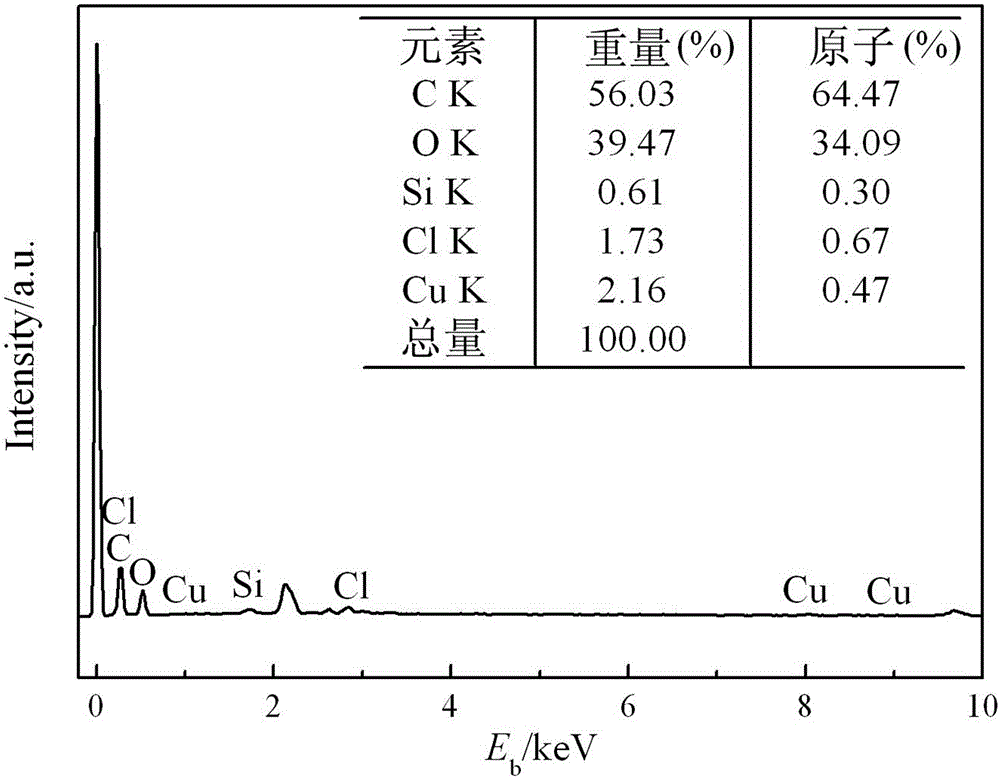

[0044]Slowly add a certain amount of sodium silicate aqueous solution into the aminoethylaminopropylmethyldimethoxysilane solution, while stirring the solution, and then add an appropriate amount of absolute ethanol, wherein sodium silicate aqueous solution, aminoethylammonia The volume ratio of propylmethyldimethoxysilane and absolute ethanol is 10:1:6. Use glacial acetic acid to adjust the pH to 3~4, stir well until the mixture has no suspended matter, and make a uniform sol. Put the bamboo sample into the impregnation tank, pour the sol, press the sample with a heavy object to avoid floating of the sample, vacuumize, control the vacuum pressure at -0.08Mpa, keep the pressure for 100min, and then release the pressure. Then pressurize the dipping tank to 5MPa, keep the pressure for 160min, then release the pressure, take out the bamboo wood sample, clean up the surface...

Embodiment 3

[0047] A kind of treatment method of bamboo wood mildew-proof and anticorrosion of the present invention:

[0048] Slowly add a certain amount of n-butyl titanate into the 3-aminopropyltriethoxysilane solution, while stirring the solution, and then add an appropriate amount of absolute ethanol, in which n-butyl titanate, 3-aminopropyl The volume ratio of triethoxysilane and absolute ethanol is 15:2.5:10. Use dilute hydrochloric acid to adjust the pH to 3~4, stir well until the mixture has no suspended matter, and make a uniform sol. Put the bamboo wood sample into the impregnation tank, pour in the sol, press the sample with a heavy object to avoid floating of the sample, vacuumize, control the vacuum pressure at -0.098Mpa, keep the pressure for 150min, and then release the pressure. Pressurize the dipping tank to 7MPa and keep the pressure for 240min. Then the pressure is released, the bamboo wood sample is taken out, the surface of the sample is cleaned and the impregnatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com