Wood modifying method

A wood modification and wood technology, which is applied in the direction of impregnated wood, wood impregnation, wood processing equipment, etc., can solve the problems of tree knots falling off, not forming perfect, surface cracking, etc., and achieve waterproof performance and flame retardancy enhancement, density and Increased strength and good fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

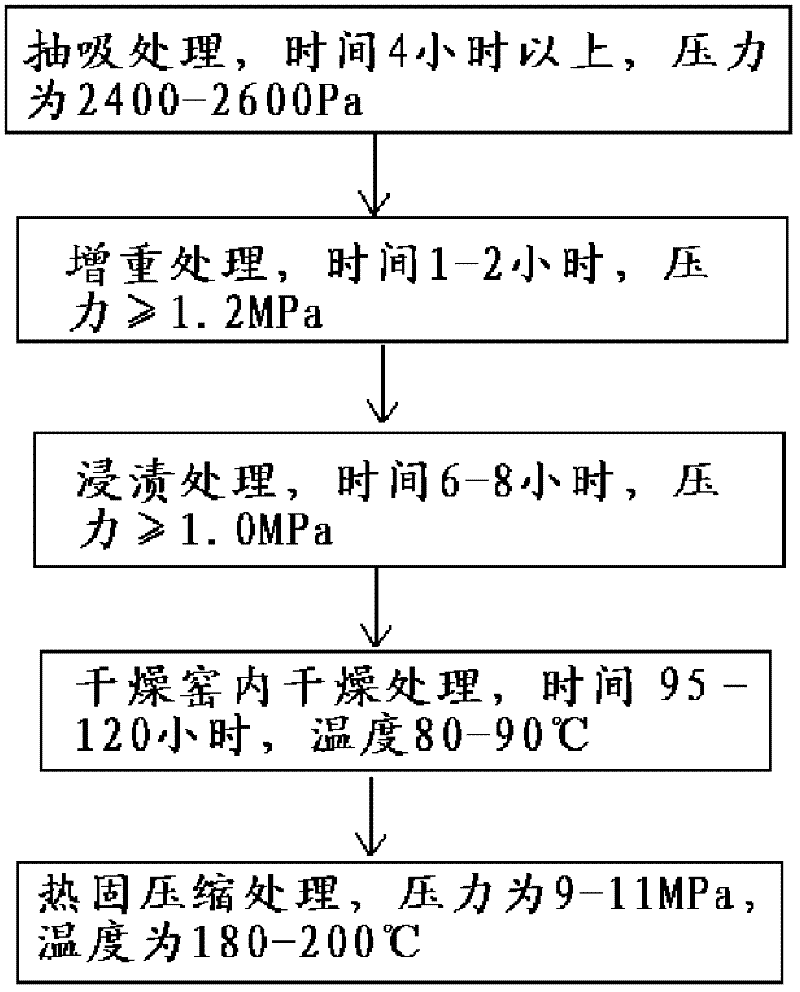

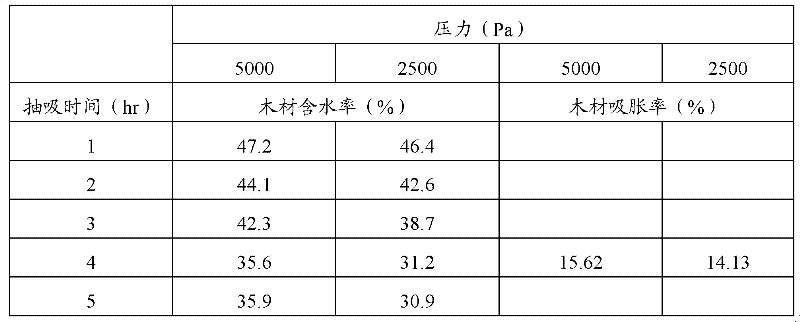

[0033] Example 1, such as figure 1 The process shown in the present invention is a wood modification method of the present invention. The low-density wood poplar with a basic moisture content of 51.3% is converted into a slab with a size of 1300*130*28mm, then loaded on a trolley, and sent to a vacuum pressure tank for suction treatment , The pressure in the vacuum pressure tank is set to 2500Pa, 5000Pa, and the suction time is 1, 2, 3, 4, and 5 hours respectively. Use the ST-85 digital wood moisture meter to measure the moisture content of wood, as shown in Table 1. Show:

[0034] Table 1 Under different suction time and pressure conditions, the moisture content and swelling rate of wood

[0035]

[0036] The condition of the swelling test is that the slab after suction treatment is placed in the room for 48 hours to re-moisturize, then dried to a moisture content of about 12%, and then immersed in room temperature water for 24 hours. The slab thickness swelling rate is measured....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com