Process for wood acetylation and product thereof

An acetylation and wood technology, applied in the direction of impregnating wood, wood impregnation, wood processing appliances, etc., can solve the problem of not recording, and achieve the effects of avoiding recycling, reducing aesthetic appearance, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

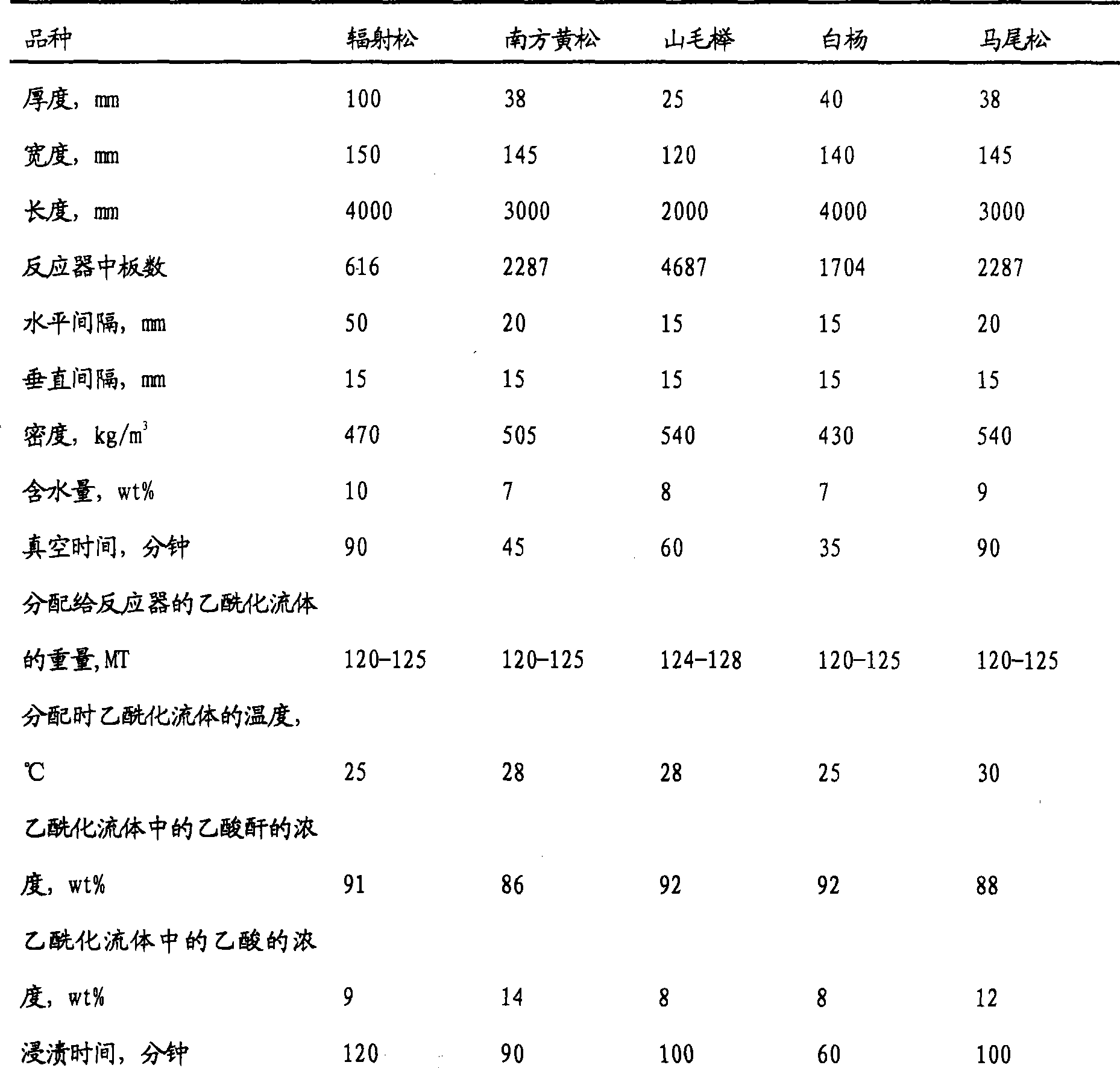

[0053] will be about 0.4M 3 Rough-sawn radiata pine boards from Chile (with 11% moisture), separated vertically and horizontally with 15mm spacers. The board is 3.9m long x 55mm thick by 130mm wide and consists mostly of sapwood with some corewood. Put the wood in a liquid-filled capacity of 2.5M 3 in the reaction pressure vessel. The reaction vessel was equipped with a gas circulation loop.

[0054] A vacuum of 0.1 to 0.2 bar absolute is applied for 30 minutes. Immersion fluid (90% acetic anhydride and 10% acetic acid at ambient temperature) was used to release the vacuum and flood each panel. Vacuum is applied during filling. The absolute pressure was increased to 10 bar with nitrogen and maintained for 90 minutes. The free liquid was drained leaving a saturated board containing 1.5 to 1.7 kg of liquid per kg of wood.

[0055] Nitrogen saturated with acetic anhydride was used as the heating medium for the acetylation reaction. The purpose of saturating the gas with a...

Embodiment 2

[0063] will be about 0.4M 3 Rough-sawn Southern Ponderosa Pine boards (with 12% moisture) were separated vertically and horizontally with 15 mm spacers. The board is 3.9m long x 40mm thick by 140mm wide and consists of sapwood with some core material. Put the wood in a liquid-filled capacity of 2.5M 3 in the reaction pressure vessel. The reaction vessel was equipped with a gas circulation loop.

[0064] A vacuum of 0.1 to 0.2 bar absolute is applied for 30 minutes. Immersion fluid (92% acetic anhydride and 8% acetic acid at ambient temperature) was used to release the vacuum and flood each panel. Vacuum is applied during filling. The absolute pressure was increased to 10 bar using nitrogen and maintained for 60 minutes. The free liquid is drained, leaving a saturated board containing 1.0 to 1.2 kg of liquid per kg of wood.

[0065] Nitrogen saturated with acetic anhydride vapor was used as the heating medium for the acetylation reaction. The purpose of saturating the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com