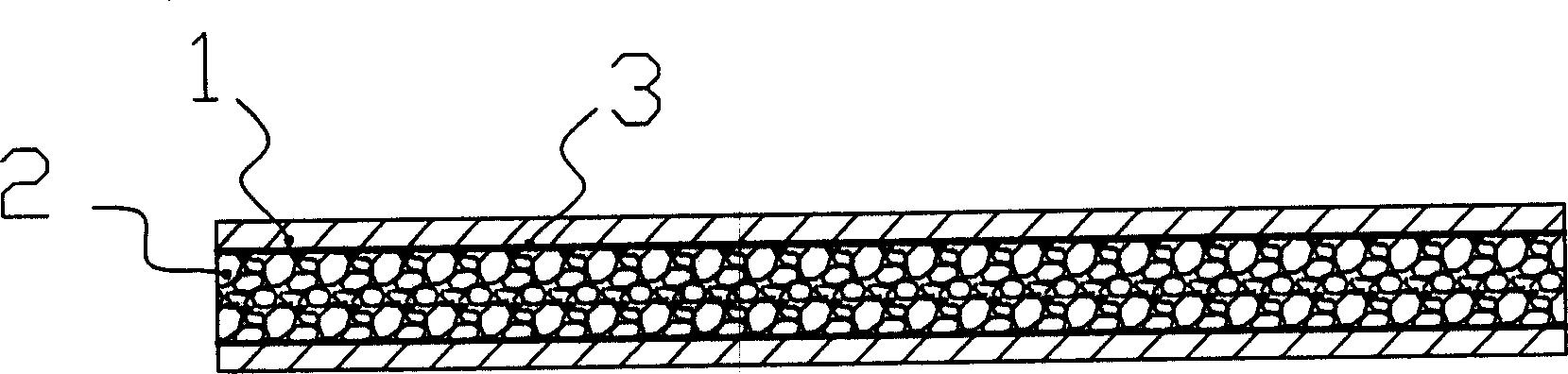

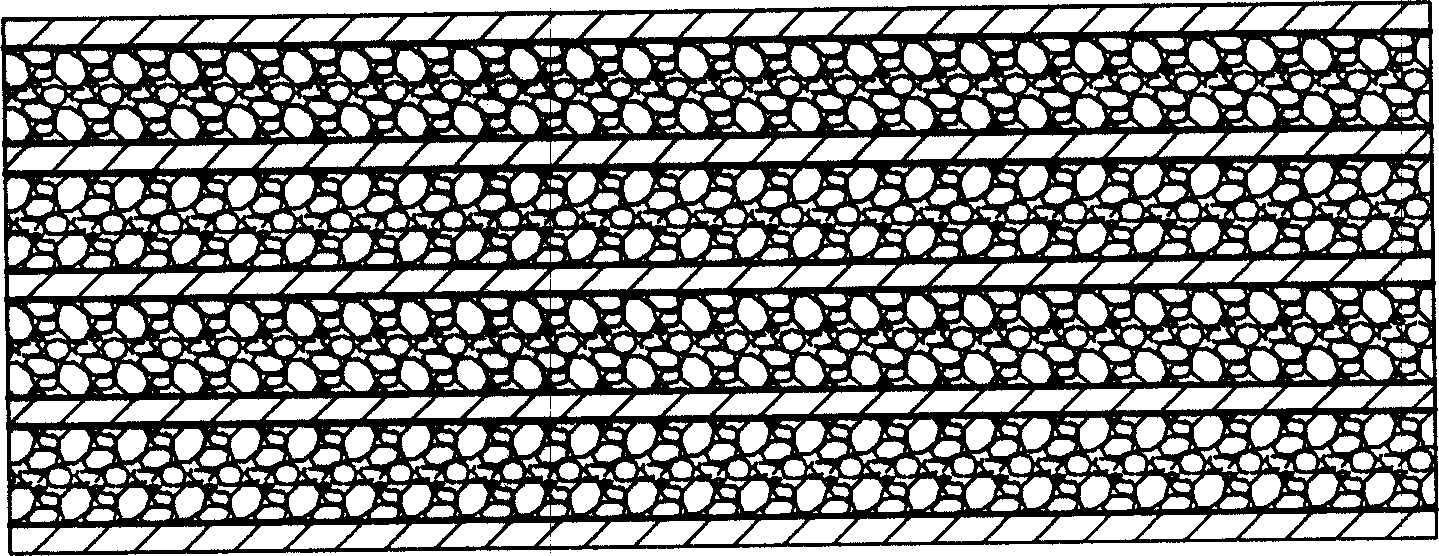

Multilayer flame-retardant composite wood and method for producing same

A technology for synthesizing wood and flame-retardant layers, which is applied in the direction of manufacturing tools, wood-layered products, chemical instruments and methods, etc., can solve the problems of fire prevention indicators failing to meet requirements, environmental protection and safety performance, and fire prevention. Achieve the effects of light weight, strong bending resistance, fire resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture Embodiment 1

[0034] Flame-retardant layer manufacturing embodiment 1 is:

[0035] 1. Prepare materials according to the following composition weight ratio: 100kg of sawdust with a particle diameter between 1 and 2 mm; 25kg of talc powder; 25kg of Shuangfei powder; 25kg of perlite; 280kg of magnesium chloride;

[0036] 2. Proportion magnesium chloride with water to form a liquid with a density of 1.4;

[0037] 3. Mix the liquid with other raw materials and pour into the mixer to stir into a paste slurry;

[0038] 4. The upper plane press machine makes a 2 mm thick sheet.

manufacture Embodiment 2

[0039] Flame-retardant layer manufacturing embodiment 2 is:

[0040] 1. Prepare materials according to the following composition and weight ratio: 125kg of peanut shells with a particle diameter between 1 and 2 mm; 30kg of talc powder; 30kg of Shuangfei powder; 30kg of perlite; 315kg of magnesium chloride;

[0041] 2. Proportion magnesium chloride with water into a liquid with a density of 1.45;

[0042] 3. Pour the liquid and other raw materials into the mixer and stir into a paste slurry;

[0043] 4. The upper plane press machine makes 10 mm thick sheet.

manufacture Embodiment 3

[0044] Flame-retardant layer manufacturing embodiment 3 is:

[0045] 1. Prepare materials according to the following composition and weight ratio: 150kg of rice husk and barley husk with a particle diameter of 1-2mm or one or more of them mixed; 35kg of talc powder; 35kg of Shuangfei powder; 35kg of perlite; Magnesium chloride 350kg; Magnesium oxide 550kg;

[0046] 2. Proportion magnesium chloride with water to form a liquid with a density of 1.5;

[0047] 3. Pour the liquid and other raw materials into the mixer and stir into a paste slurry;

[0048] 4. The upper plane press is used to make a 20mm thick sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com