Small wood integrated shaving thin-wood manufacture method and leveling drying device thereof

A manufacturing method and technology of small-diameter wood, which is applied in the manufacture of thin wood chips, impregnated wood, and tool manufacturing. It can solve the problems of easy deformation and warping, restrictions on the use range of plantation wood, and large growth stress, so as to reduce cutting. The effect of reducing resistance, saving heat energy consumption, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

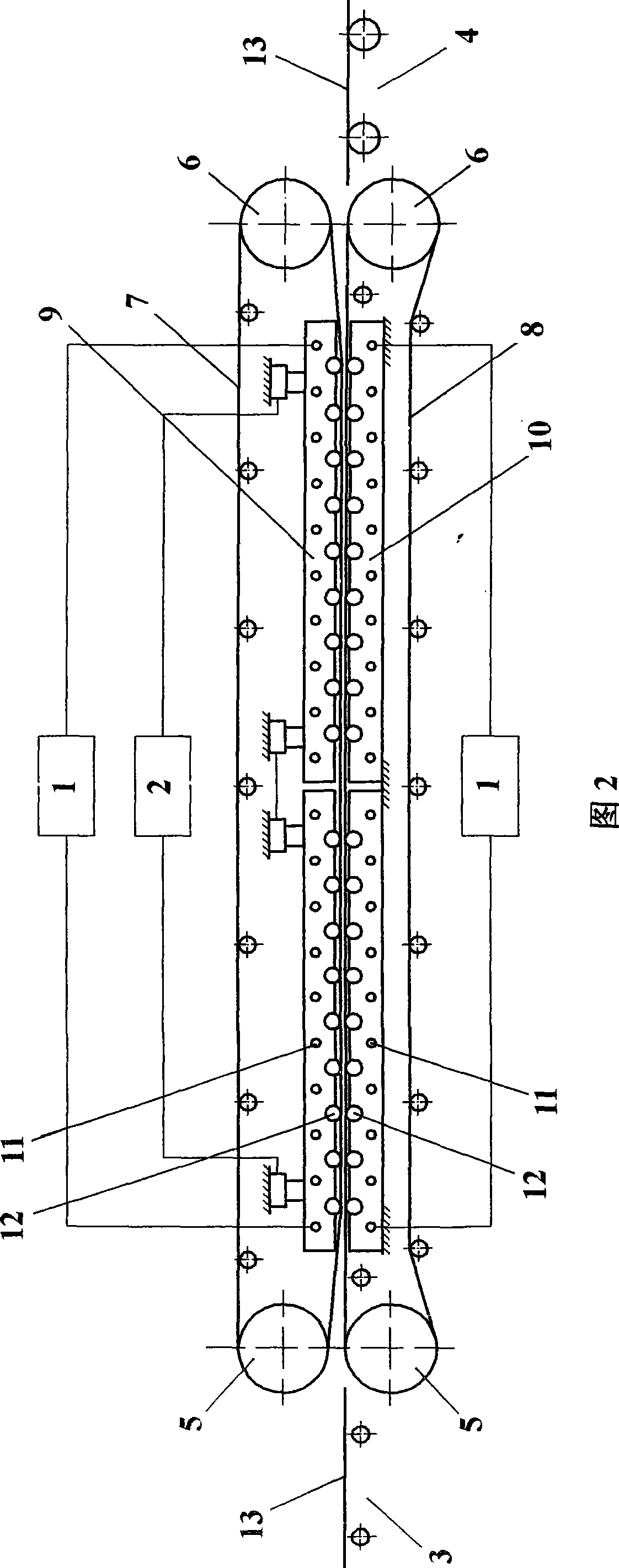

[0043] Example 1: Continuous high-temperature ironing, leveling and drying machine dedicated to the present invention

[0044] Referring to Figure 2, this continuous high-temperature ironing and leveling dryer includes a frame (omitted from the figure), an oil medium heating and circulation device 1, a pressure and gap adjustment device 2, a front rolling table 3, and a rear rolling table 4, A long annular upper steel belt 7 and a lower steel belt 8 driven by the tension roller 5 and the driving roller 6 are arranged up and down between the front rolling table and the rear rolling table. Two upper hot plates 9 arranged in front and back are arranged on the top of the lower part of the upper steel belt, and two lower hot plates 10 arranged in front and rear are arranged under the upper part of the lower steel belt; There are heating pipes 11 respectively, and several rolling rollers 12 protruding from the surfaces of the upper and lower hot plates are embedded in the lower part...

Embodiment 2—4

[0047] Embodiment 2-4: the preparation of composite reagent used in the present invention

[0048] The weight ratio (unit: kilogram) of each embodiment raw material is shown in Table 1.

[0049] The preparation method is: (taking Example 3 as an example, the preparation method is basically the same as Example 3 except that the raw material consumption is different in other embodiments)

[0050] After adding 15 kilograms of ammonium sulfite, 5 kilograms of ammonium bisulfite and 5 kilograms of urea to 175 kilograms of water, adjust the pH to 8 with ammonia water.

[0051] Table 1

[0052] Example 2 3 4 Ammonium sulfite 13 15 16 Ammonium bisulfite 4 5 6 Urea 6 5 4 water

Embodiment 5—7

[0053] Embodiment 5-7: the preparation of the moisture-curable adhesive used in the present invention

[0054] The weight ratio (unit: kilogram) of each embodiment raw material is shown in Table 2.

[0055] The preparation method is: (taking Example 6 as an example, the preparation method is basically the same as Example 6 except that the raw material consumption is different in other embodiments)

[0056] (1) 388.2 kilograms of polyethylene glycol 600 were heated and melted at a temperature of 55°C, and then 30.2 kilograms of triethylene glycol (n=150) and 10.9 kilograms of ethylene glycol (n=62) were added and mixed Stir evenly to obtain a polyethylene glycol mixture;

[0057] (2) the vitriol oil of 4.5 kilograms is added in the butanone of 495 kilograms, must add the butanone solution of vitriol oil;

[0058] (3) drop the polyethylene glycol mixed solution into the reactor, first drop into 80% of the methyl ethyl ketone solution that is added with concentrated sulfuric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com