Test method for lossless monitoring and detection for material accelerated corrosion under simulated marine environment

A marine environment, accelerated corrosion technology, applied in analytical materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve the problem of difficult to quickly and accurately evaluate the corrosion resistance of materials, and achieve low cost, convenient use, and sensitivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

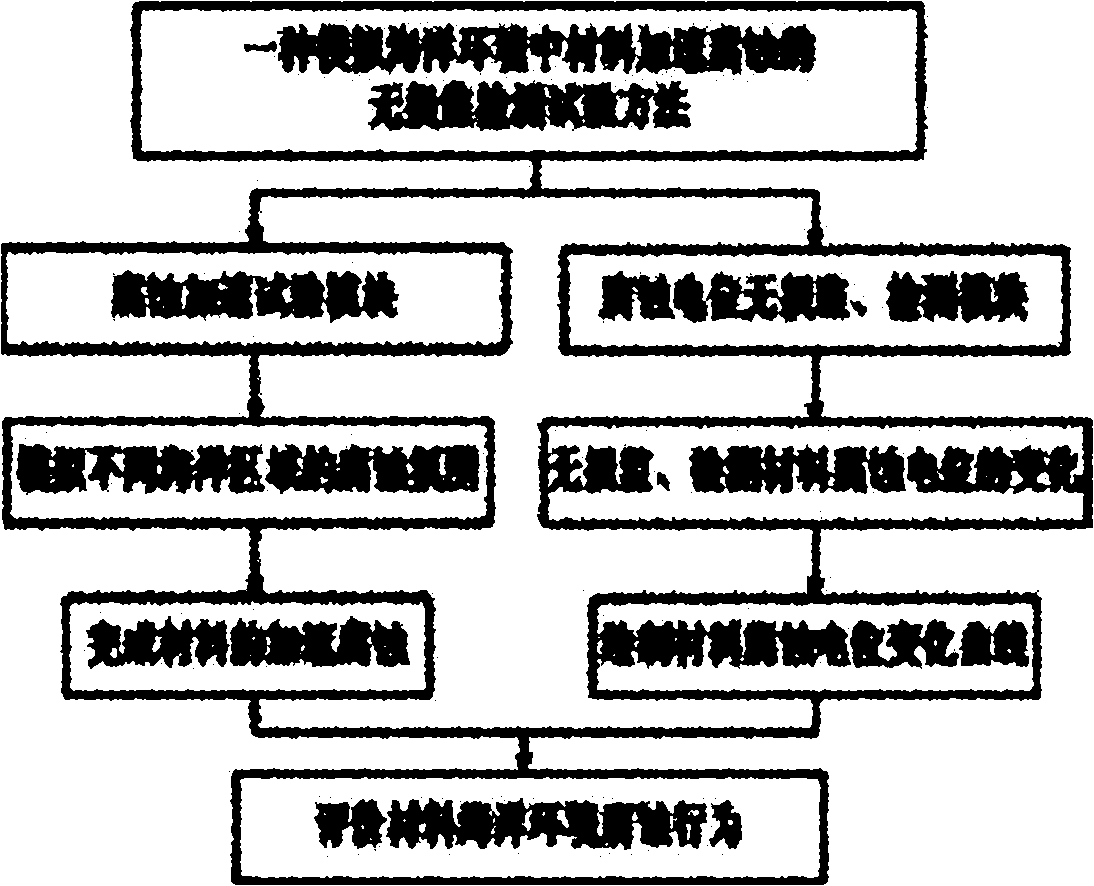

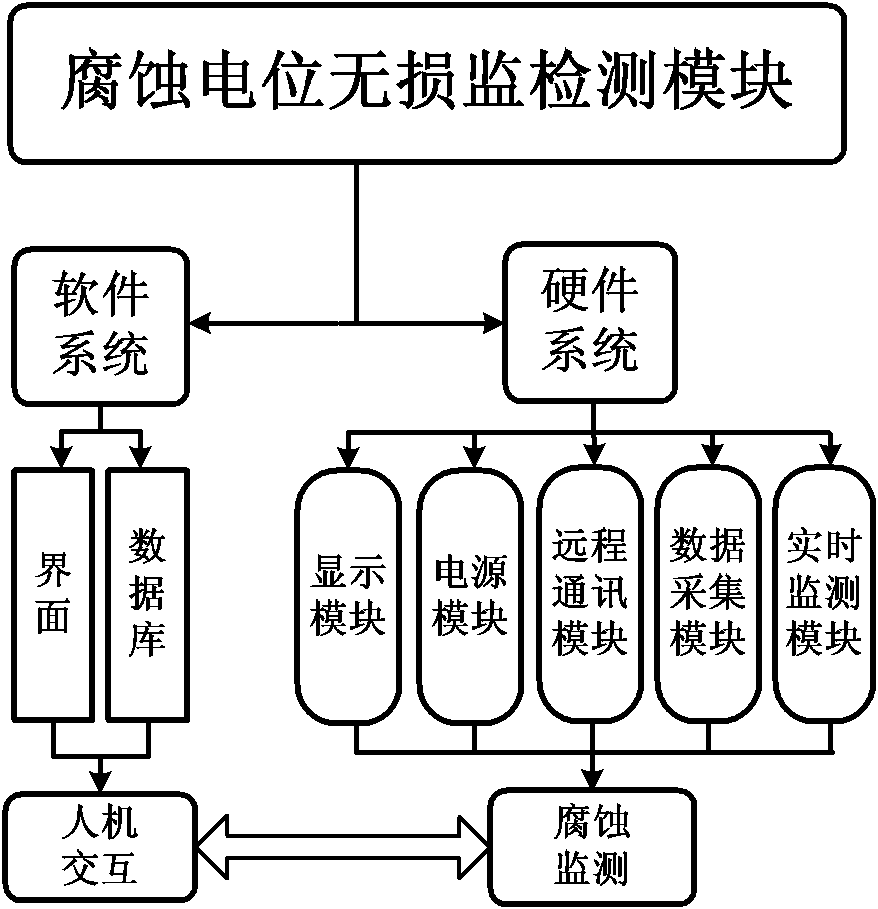

[0044] A non-destructive monitoring and testing method for simulating accelerated corrosion of materials in a marine environment, the flow chart of which is shown in figure 1 shown. The realization of this method requires the synergistic effect of the accelerated corrosion test module for simulating the marine environment and the non-destructive monitoring and detection module for corrosion potential.

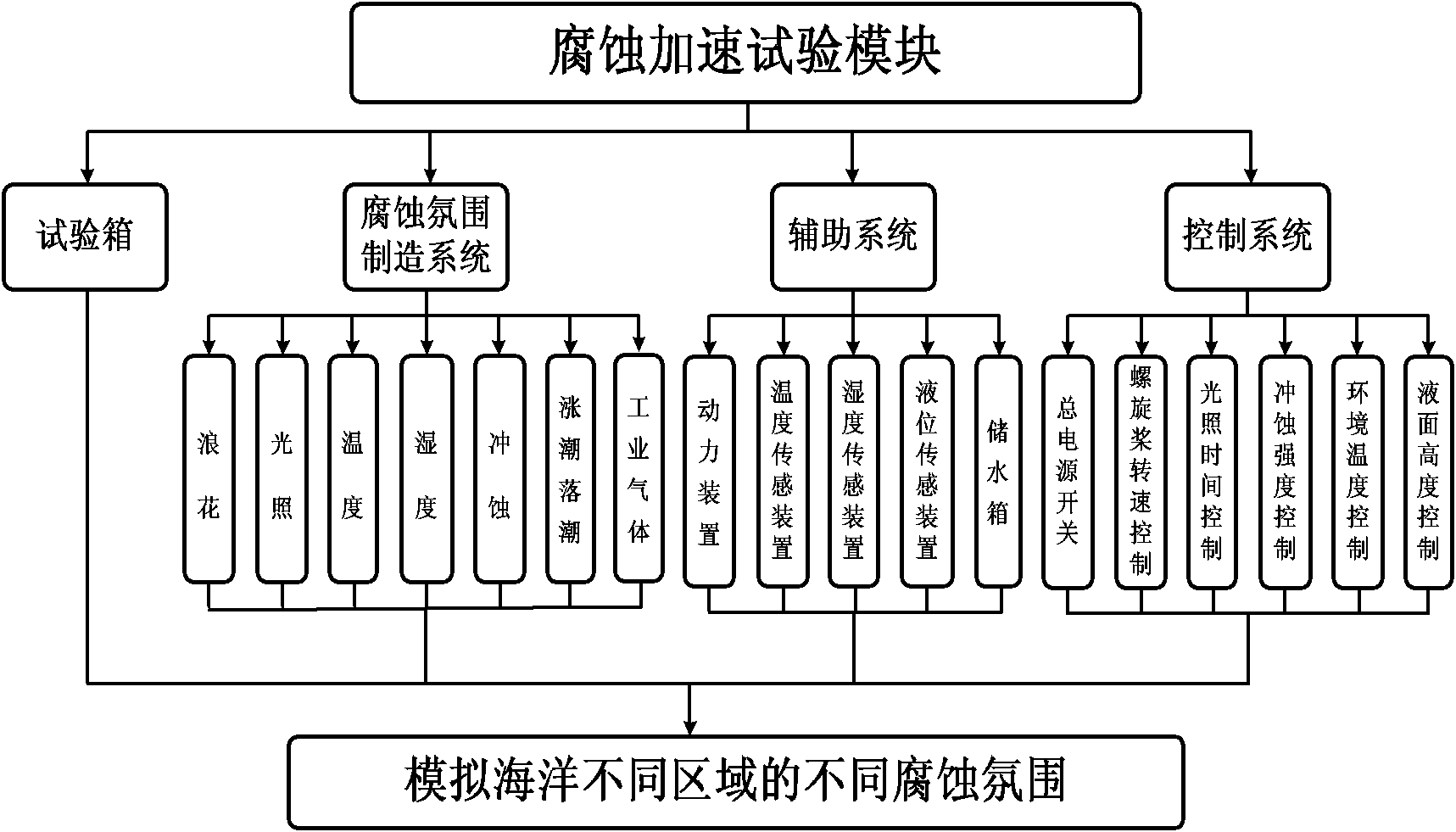

[0045] The corrosion acceleration test module simulates the marine atmosphere area, splash area, tidal range area, full immersion area and sea mud area in different sea areas by controlling the propeller speed, temperature, humidity, pH value, light, precipitation and other factors. According to the sea environment that needs to be simulated, the required motor speed is calculated through the formula of "International Wave Level Table". When the working environment of the test material is in slight waves or small waves, the motor speed is not high at this time, and the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com