An industrial atmospheric corrosion resistant rebar and a production method thereof

A technology of atmospheric corrosion and production method, which is applied in the field of corrosion-resistant construction steel, can solve the problems of restricting wide-scale promotion and use, huge demand for corrosion-resistant steel bars, and unsatisfactory corrosion resistance, so as to inhibit surface enrichment and solve the problem of casting Surface quality problems of billets and rolled products, the effect of cost satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below through examples.

[0028] The typical composition of this patent is shown in Table 1, and Table 2 shows the structure and mechanical properties of the steel.

[0029] Table 1 Typical chemical composition of the steel grade of the present invention

[0030]

[0031] Table 2 Microstructure and mechanical properties

[0032]

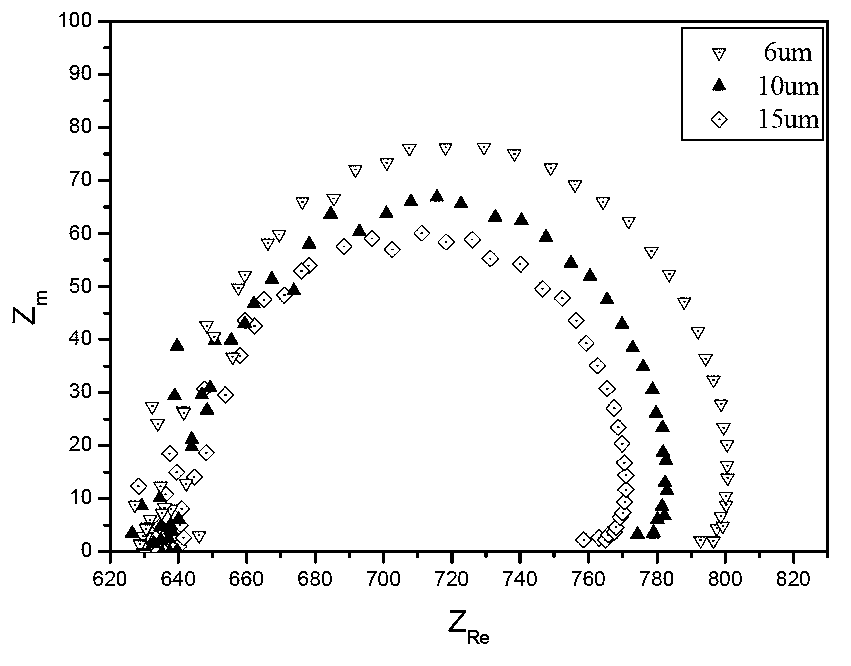

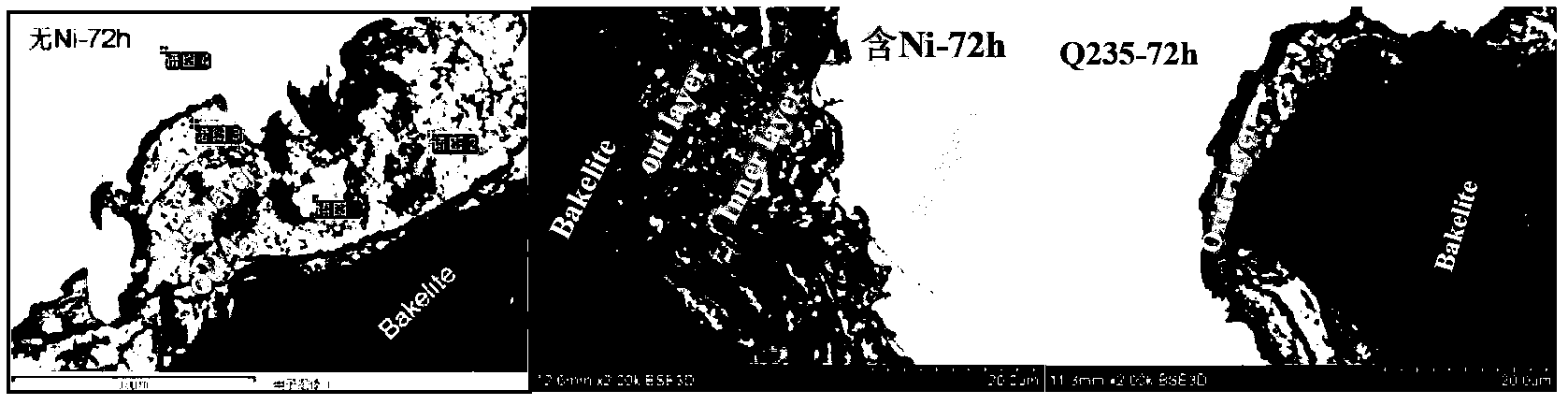

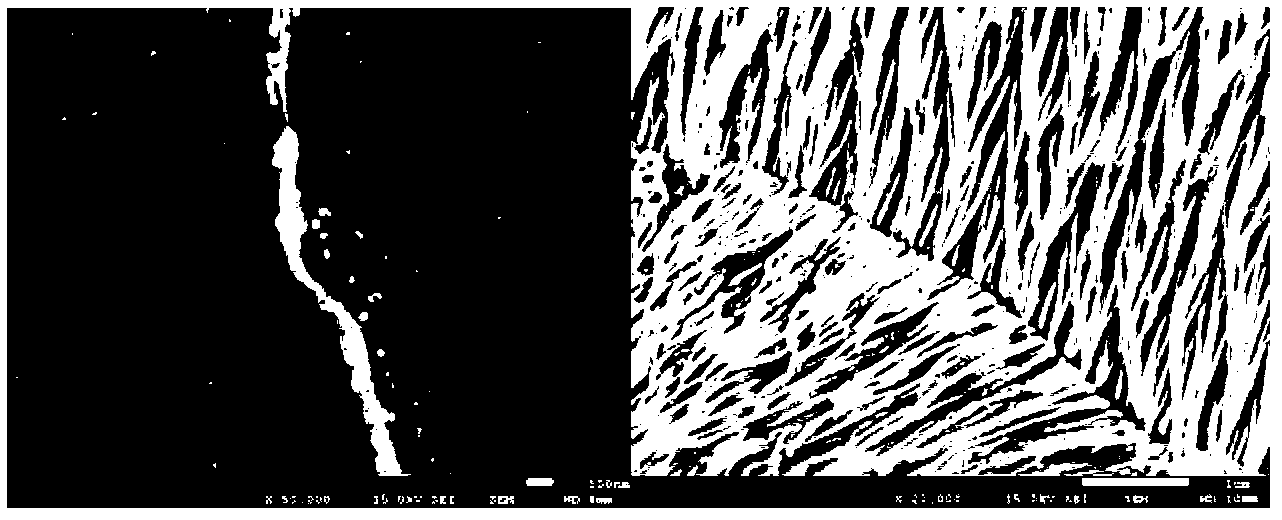

[0033] In order to measure the corrosion resistance level of the steel in this patent, the steel type in the patent of the present invention is recorded as 1# steel, and the corrosion resistance of steel containing 0.3% Ni (recorded as 2#) and Q235 steel are compared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com