Bending restraining type shear wall with slideable stiffening shaped steel and internally embedded steel plate

A shear wall and section steel technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of low economic benefit, increase cost, increase structural quality, etc., and achieve the effects of good seismic performance, cost saving, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

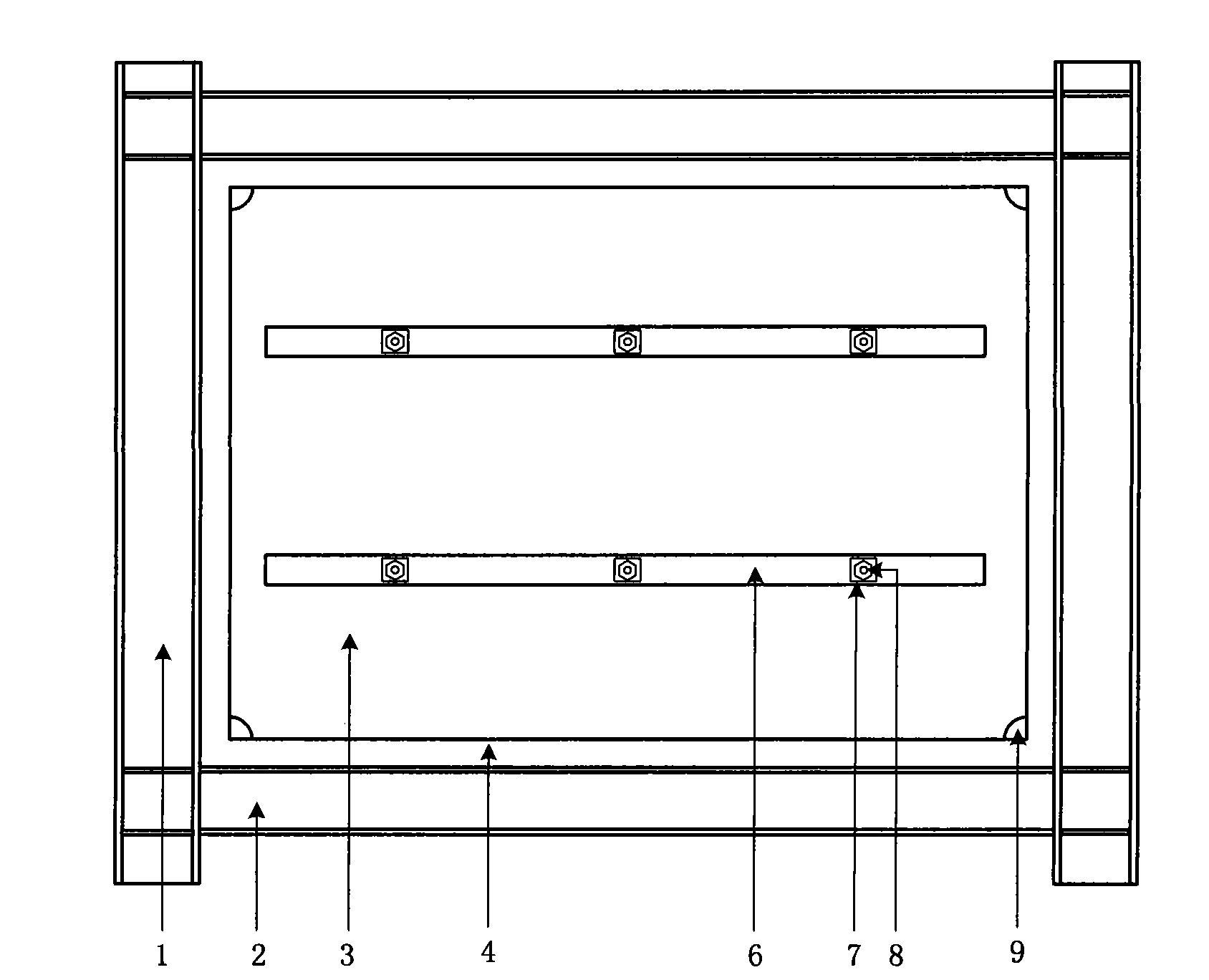

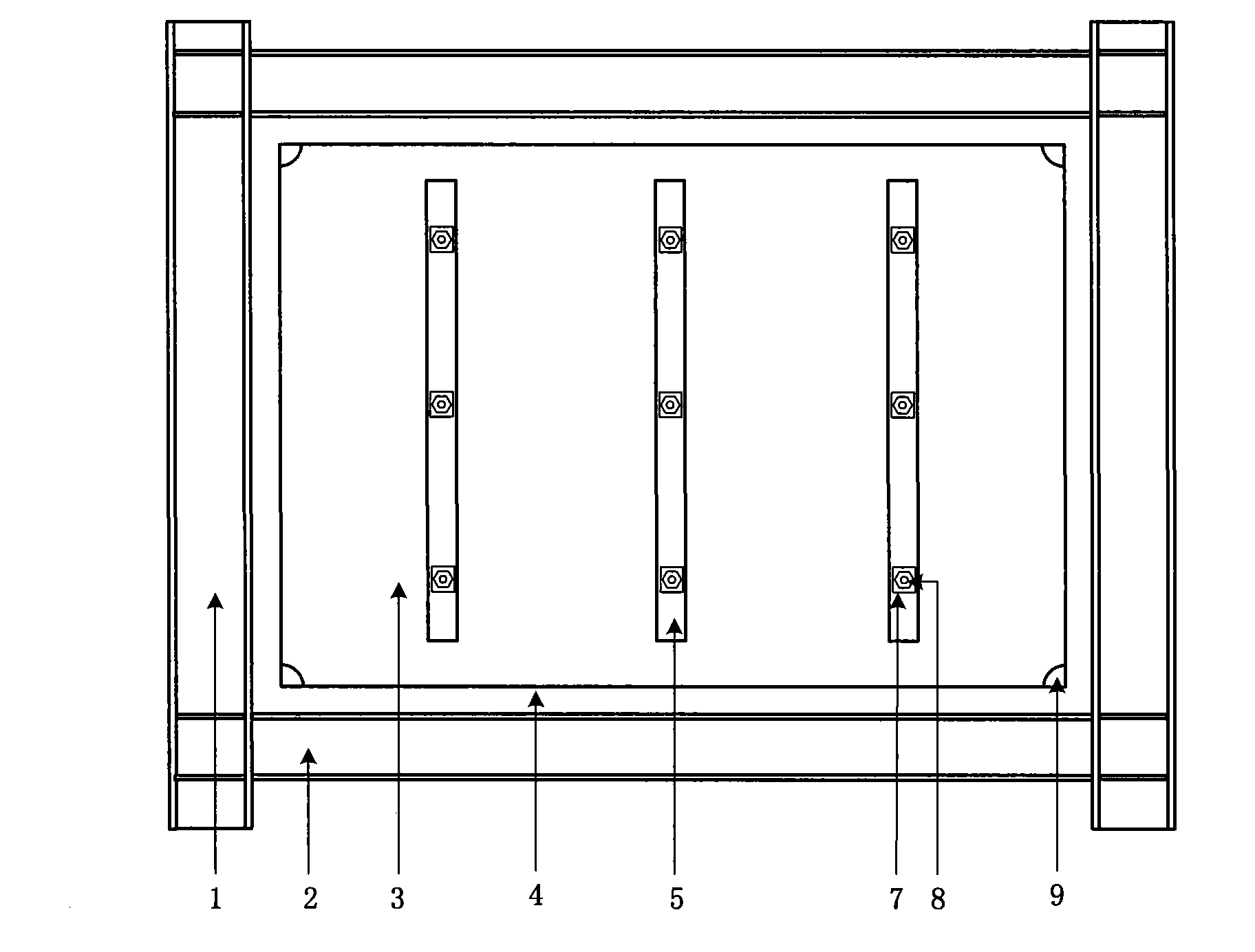

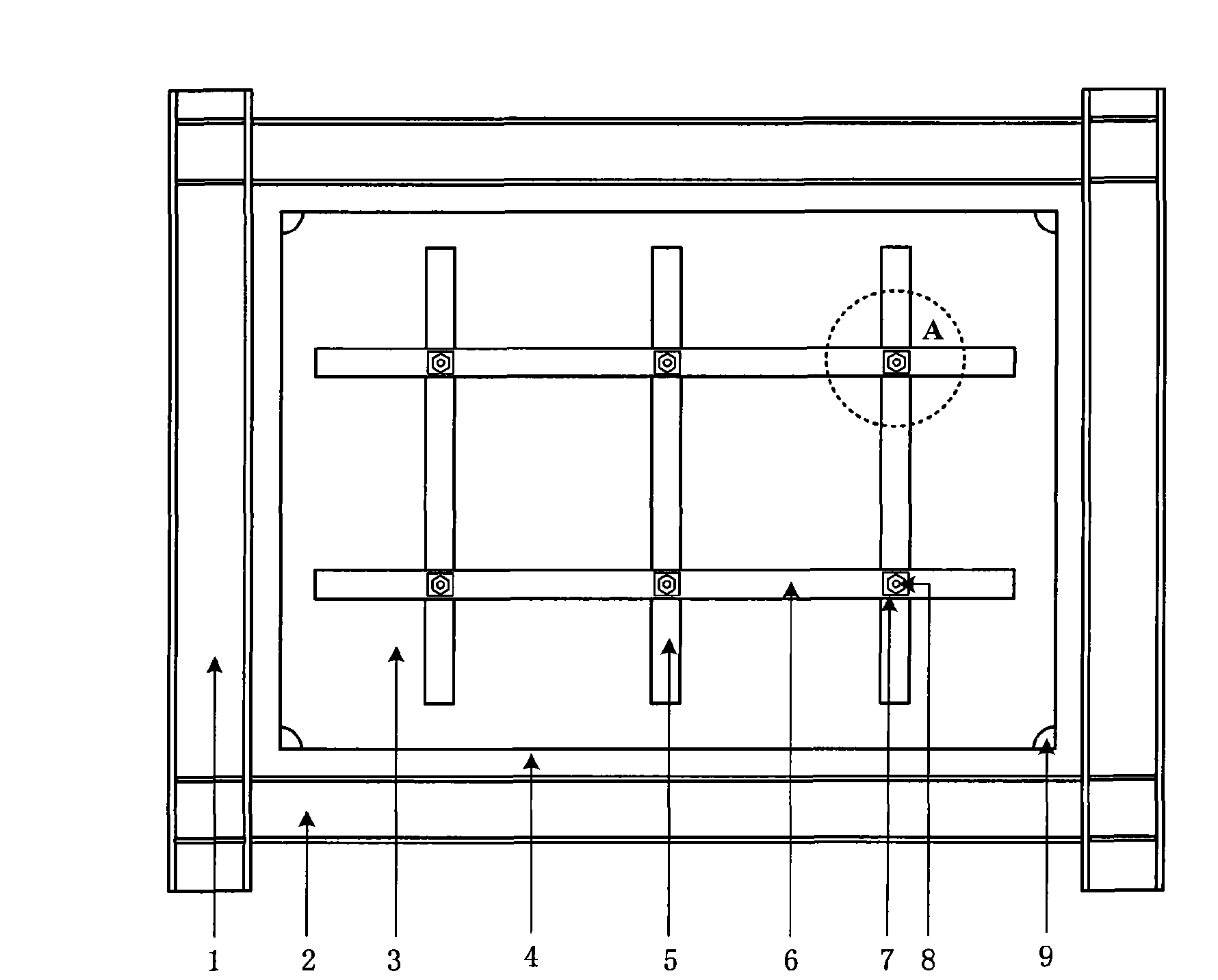

[0023] Attached below figure 1 ~6 specifies the buckling-inhibited shear wall in which the stiffened steel and the embedded steel plate can slide.

[0024] A buckling-inhibited shear wall in which stiffened section steel and embedded steel plates can slide, mainly composed of embedded steel plates, section steel stiffeners, fishplates and edge members, such as Figure 1~4 As shown, it contains the following components:

[0025] 1 - edge column;

[0026] 2 - edge beam;

[0027] 3- Embedded steel plate;

[0028] 4- fish plate;

[0029] 5-vertical steel stiffener;

[0030] 5-1-I-shaped steel;

[0031] 5-2-box-shaped steel;

[0032] 5-3-C section steel;

[0033] 5-4-L section steel;

[0034] 5-5-rolled hat-shaped steel;

[0035] 6-Transverse section steel stiffener;

[0036] 6-1-I-shaped steel;

[0037] 6-2-box-shaped steel;

[0038] 6-3-C type steel;

[0039] 6-4-L-shaped steel;

[0040] 6-5-Crimped hat-shaped steel;

[0041] 7-steel backing plate;

[0042] 8 - con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com