Pseudo-static testing device for concrete columns after non-peripheral fire exposure and implementation method thereof

A technology of concrete column and test device, which is applied in measurement device, vibration test, test of machine/structural components, etc. Installation of horizontal tension-compression servo loading device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

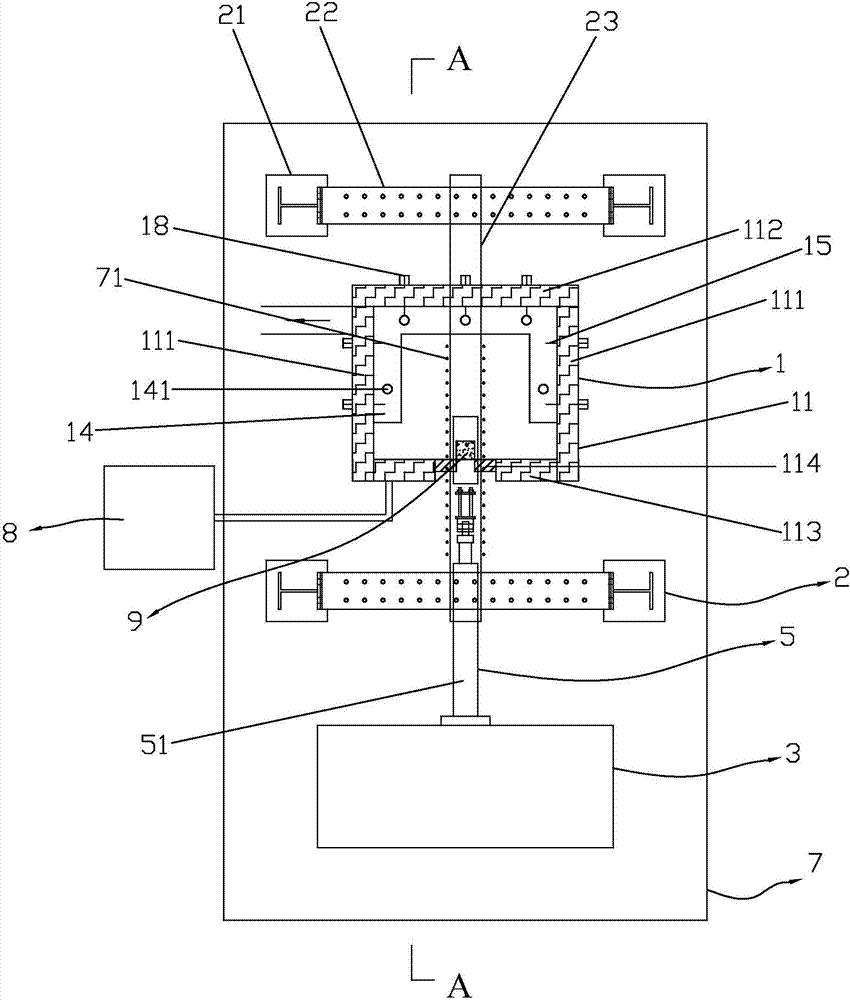

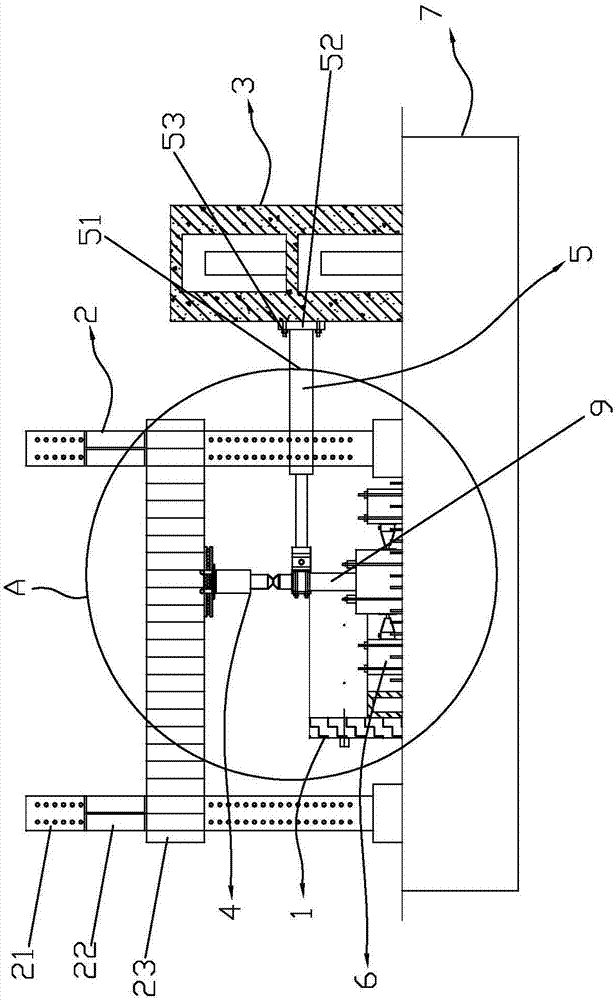

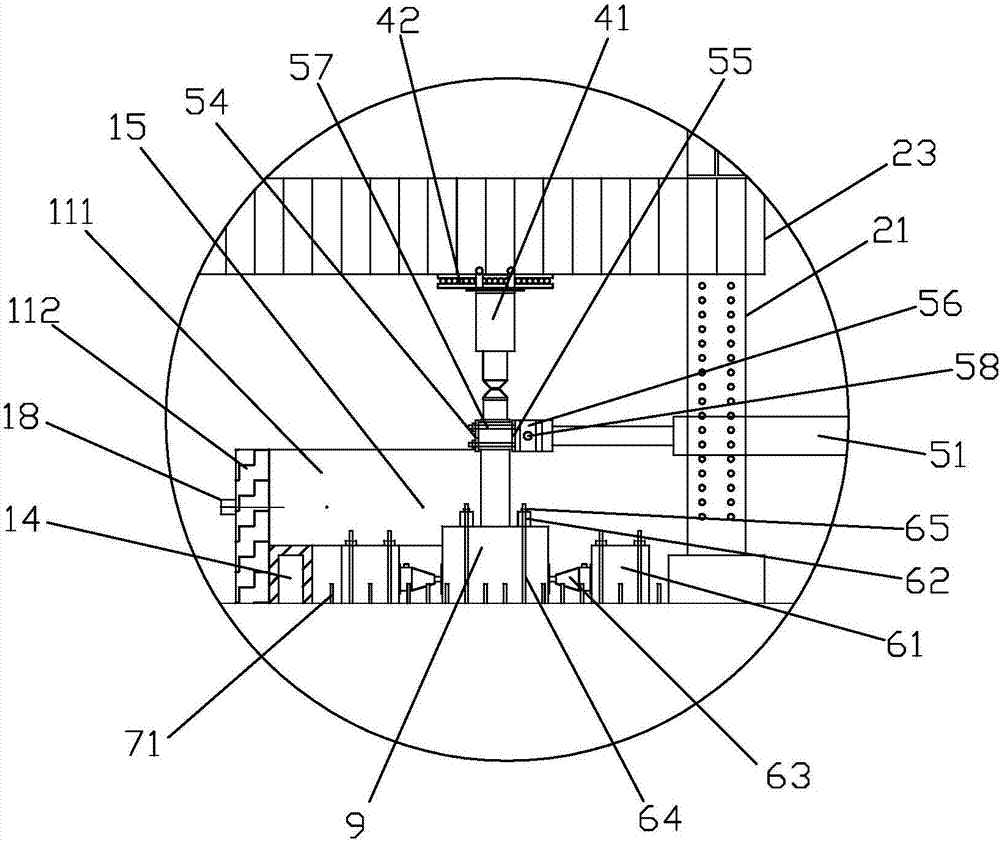

[0040] combine Figure 1 to Figure 6 , the quasi-static test device for non-surrounded concrete columns after fire in this embodiment includes a furnace body 1, a vertical reaction frame 2, a horizontal reaction wall 3, a vertical load loading device 4, a horizontal tension and compression servo loading device 5, Fixtures 6 , base platform 7 , data acquisition system and control center 8 . The basic platform 7 is used as the foundation of the furnace body 1, the vertical reaction frame 2, the horizontal reaction wall 3 and the fixing device 6. The vertical reaction frame 2 is composed of four steel columns 21, two longitudinal steel beams 22, and a middle horizontal steel beam 23. There are 2 rows of 18 ground anchors 71 pre-buried on the foundation platform 7, and the vertical distance between adjacent ground anchors 71 is 600 mm, and the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com