Prefabricated column of reserved concealed column channel, concealed column type complete assembled earthquake-resistant building and its method

A technology for prefabricated columns and buildings, applied in building structures, buildings, building components, etc., can solve the problems of assembly nodes failing to meet seismic requirements or installation requirements, and achieve the effect of shortening the construction period and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

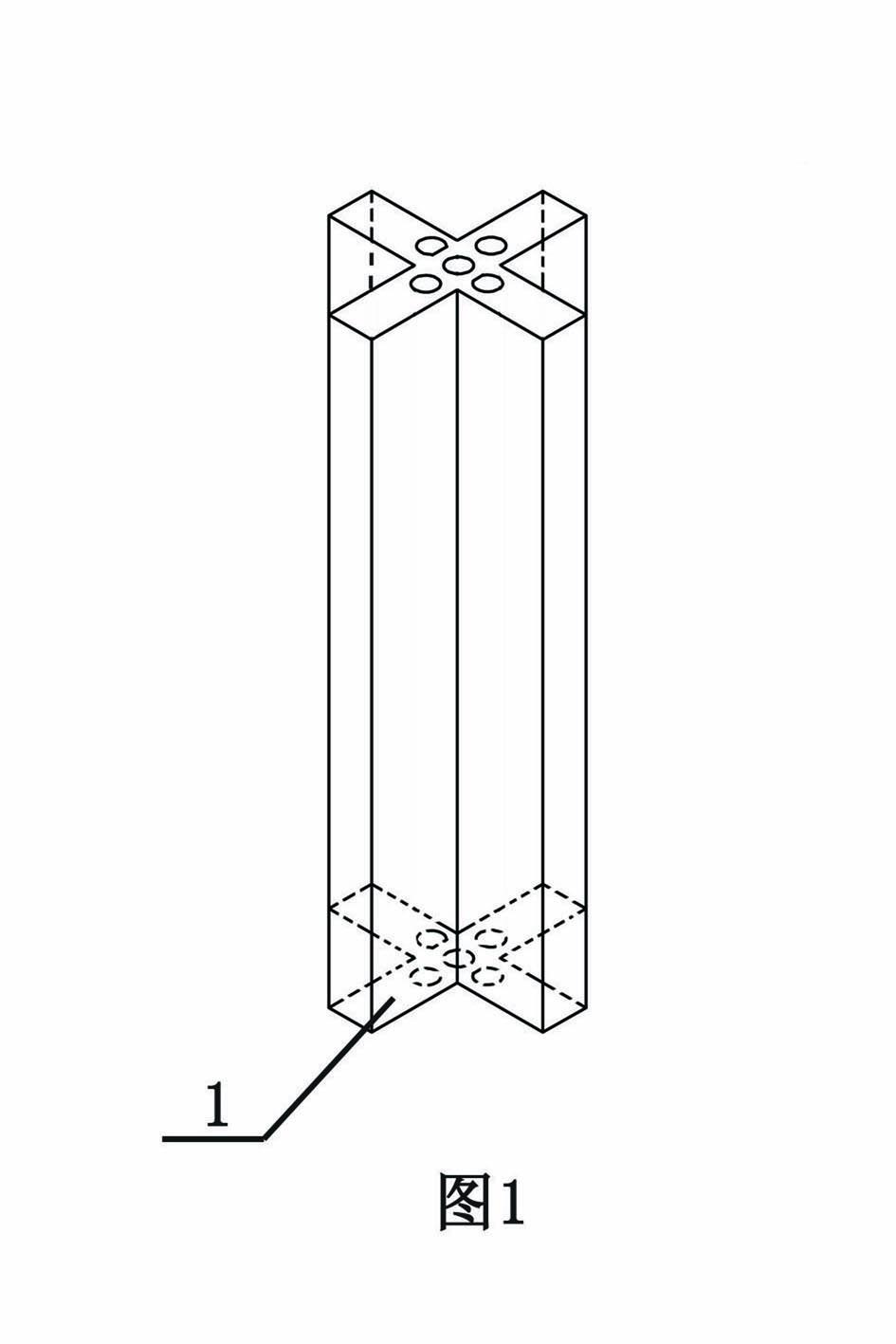

[0046] Embodiment one sees figure 1The feature of this prefabricated column with reserved hidden column channel is that the cross section is cross-shaped, and the side length of the horizontal section of the column rib of the cross column 1 is not less than 800mm.

Embodiment 2

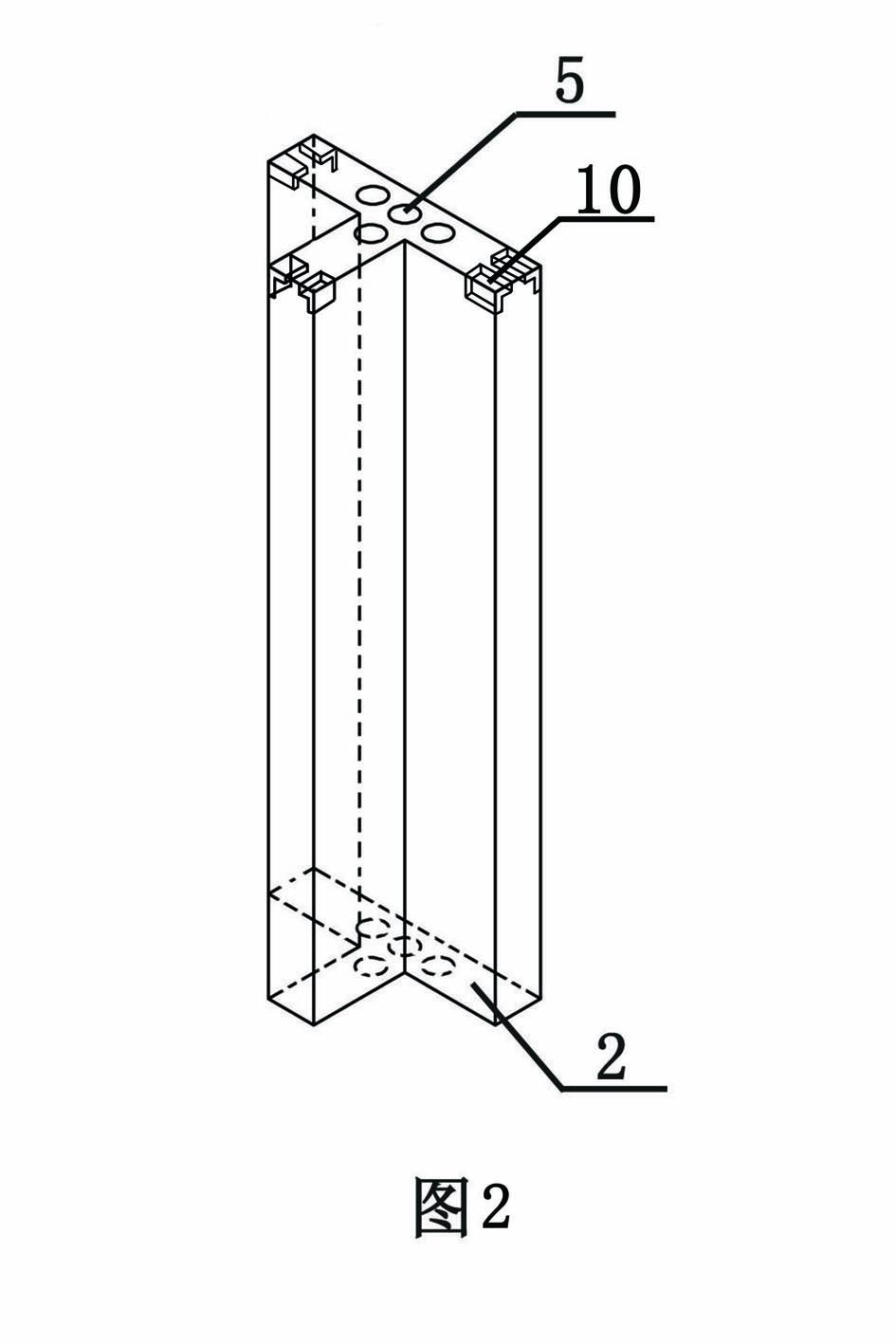

[0047] Embodiment two see figure 2 The feature of this prefabricated column with reserved hidden column channel is that the cross section is T-shaped, and the side length of the horizontal section of the column rib of the T-shaped column 2 is not less than 800mm.

Embodiment 3

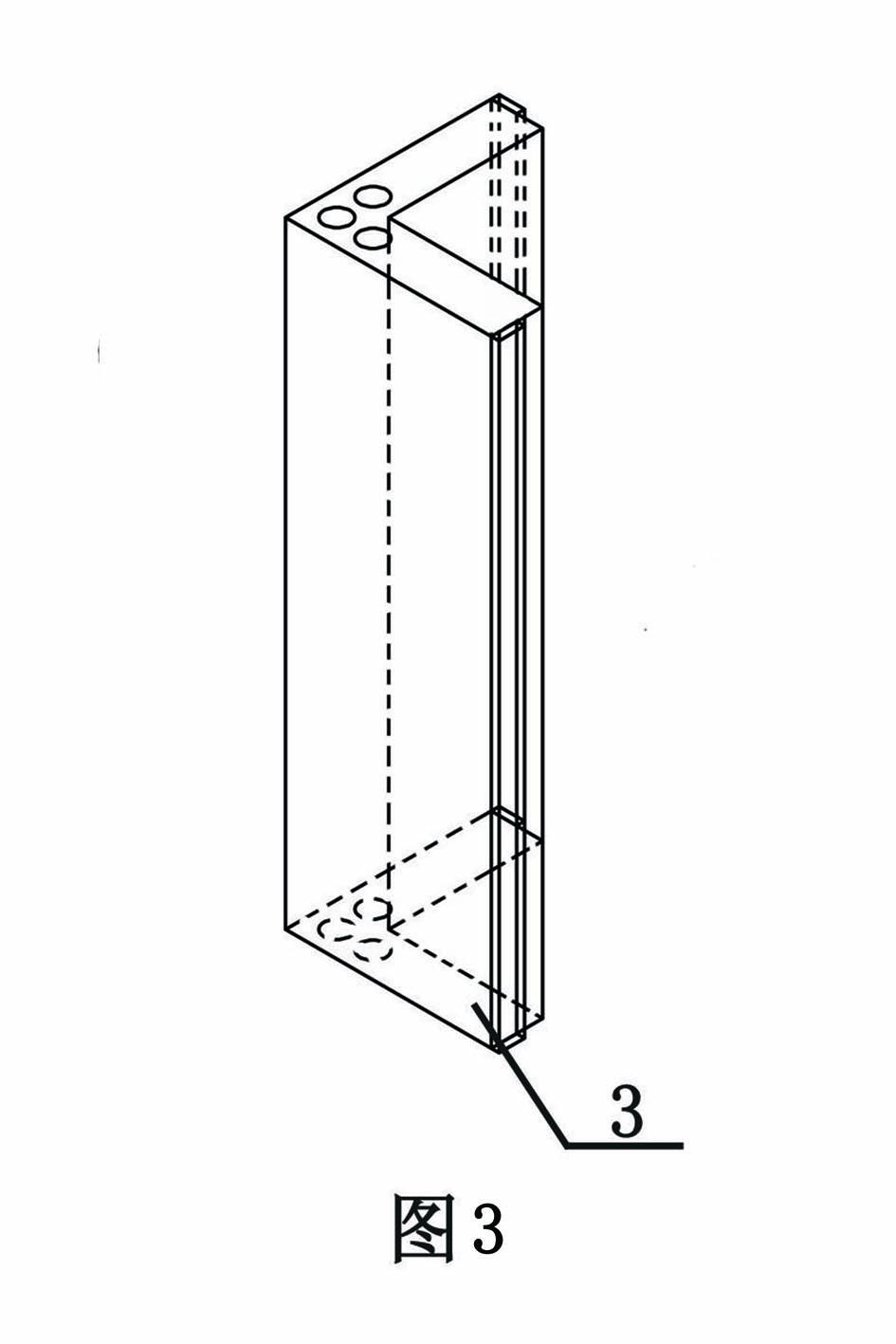

[0048] Embodiment three see image 3 The feature of this prefabricated column with reserved hidden column channel is that the cross section is L-shaped, and the side length of the horizontal section of the column rib of the corner column 3 is not less than 550mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com