Method and structure for enhancing brickwork structure and improving earthquake resistant performance of structure by using carbon fiber

A carbon fiber reinforcement, masonry structure technology, used in building maintenance, building construction, construction, etc., can solve the problem of not ensuring the co-working of carbon fiber tape and masonry structure, lack of organic connection of carbon fiber tape, increasing structure and foundation load and other problems, to achieve the effect of not occupying the original space, simple structure, and improving the seismic performance of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

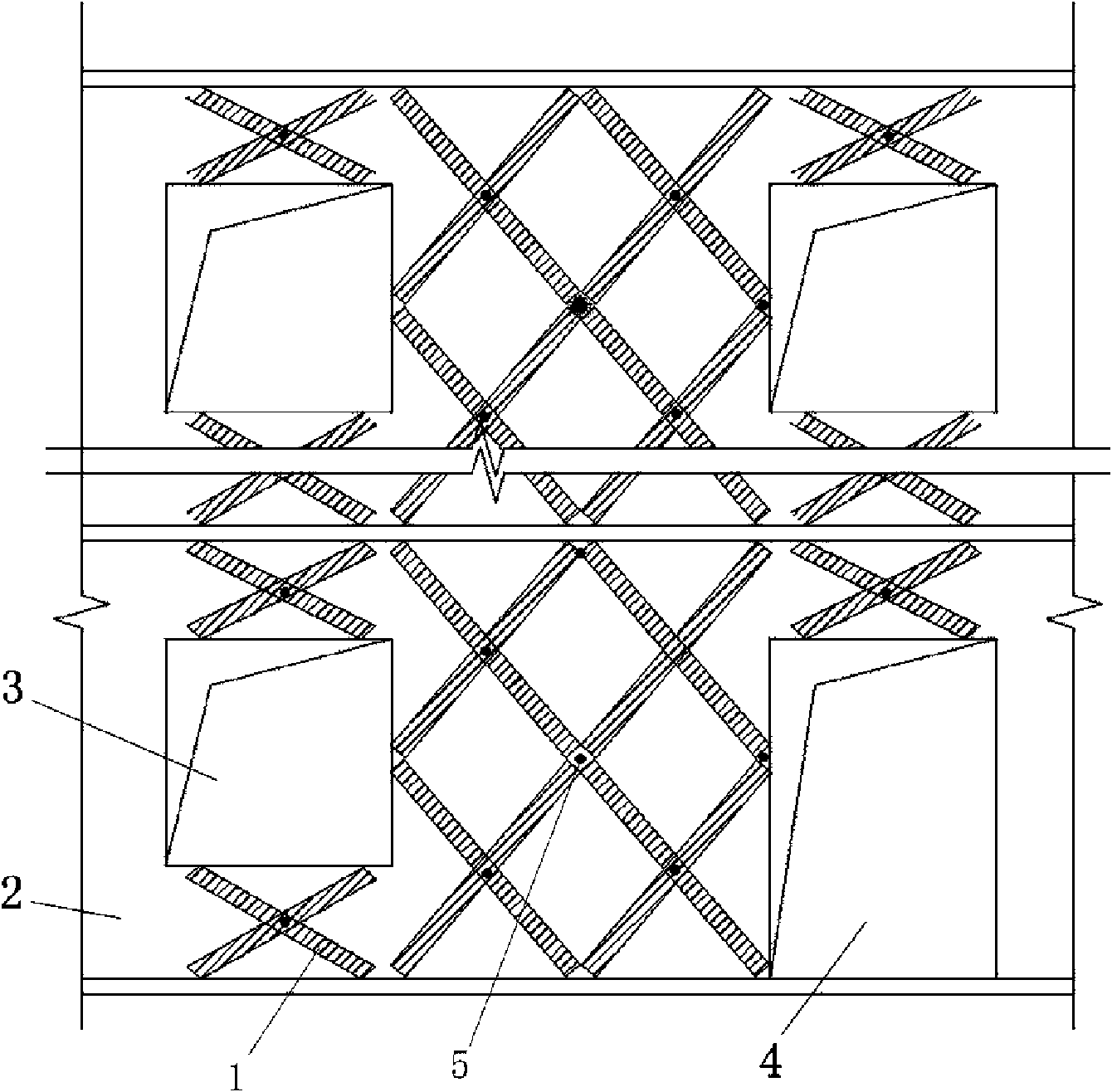

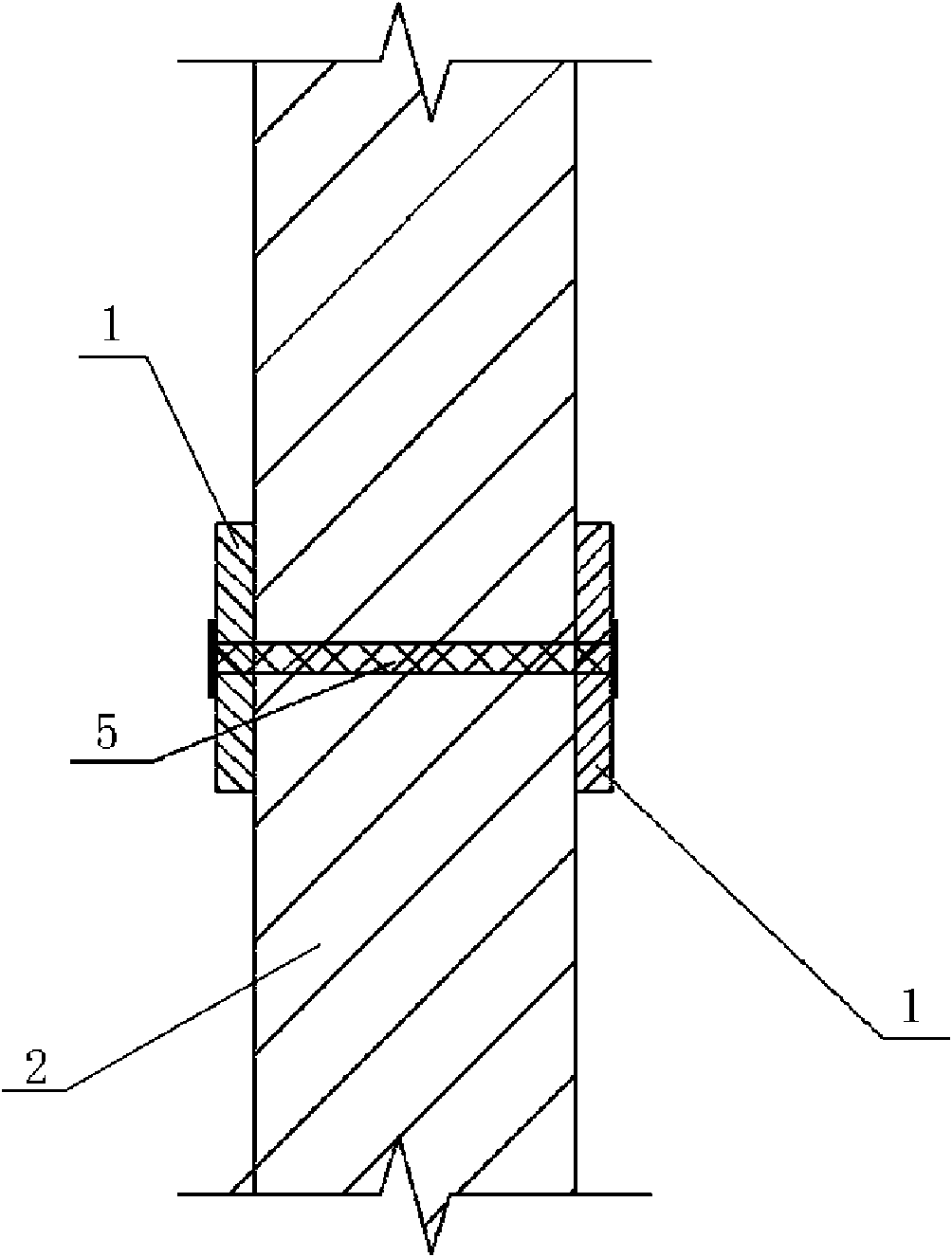

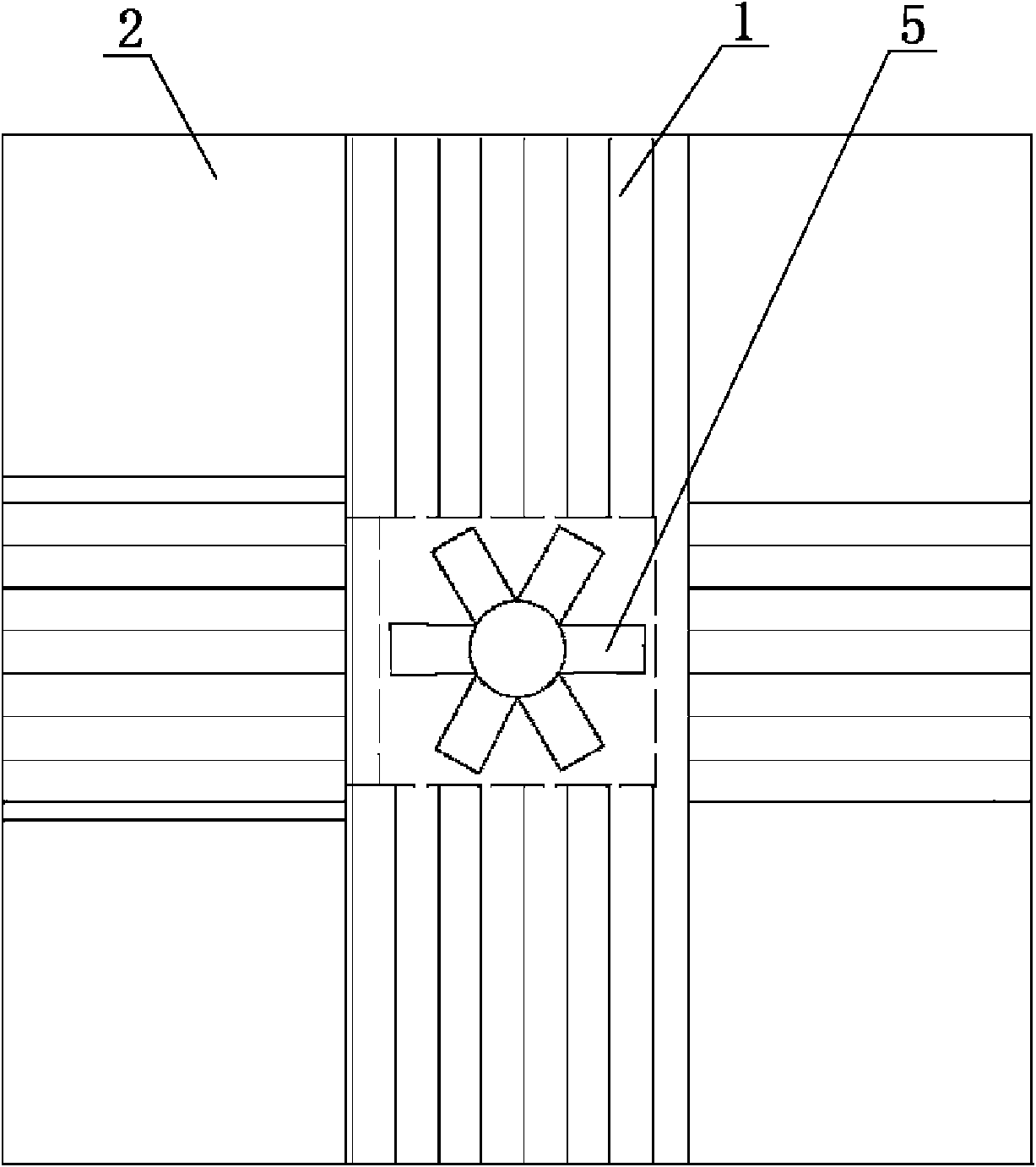

[0038] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0039] Such as Figure 1-3 Shown, the method for the seismic performance of carbon fiber reinforced masonry structure wall of the present invention, the concrete steps of its reinforcement transformation are as follows:

[0040] Step 1: Check the shear performance of the masonry structure according to the seismic design requirements, and determine the weak parts of the masonry structure wall shear performance according to the seismic design specifications, so as to determine the parts of the masonry structure wall reinforced with carbon fiber tape. Treat the surface of the oxidized and corroded masonry to meet the requirements of pasting carbon fiber cloth. The treatment method can be to plaster the surface with polymer mortar, remove the weathered and corroded parts or remove the 20mm~30mm dark gray joints, and re-plaster the surface and point out the joints. Carbon fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com