Fire-resistant and earthquake-resistant steel for construction and production method thereof

A construction steel and refractory technology, applied in the field of construction steel, can solve problems such as complex production process, achieve excellent welding performance, improve purity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

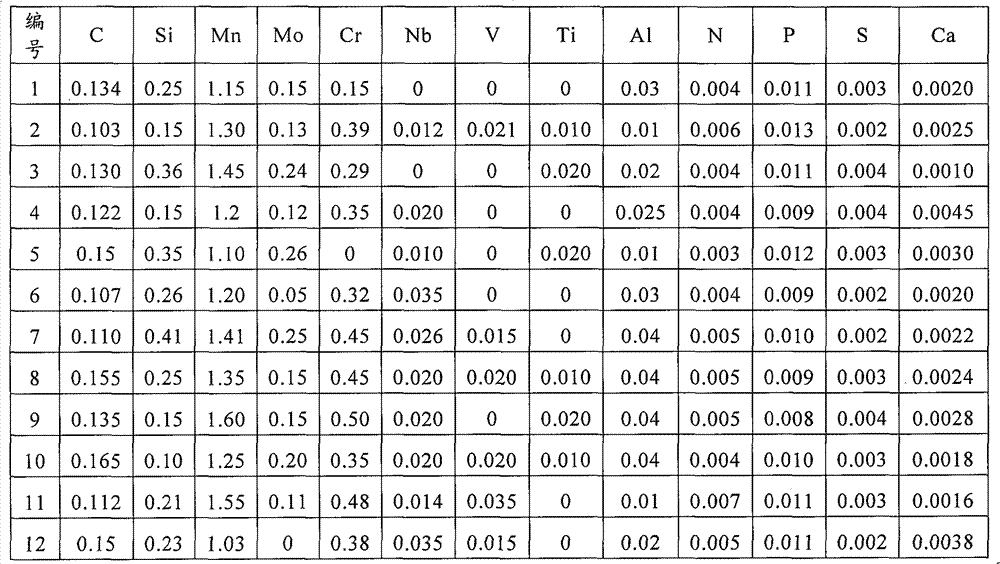

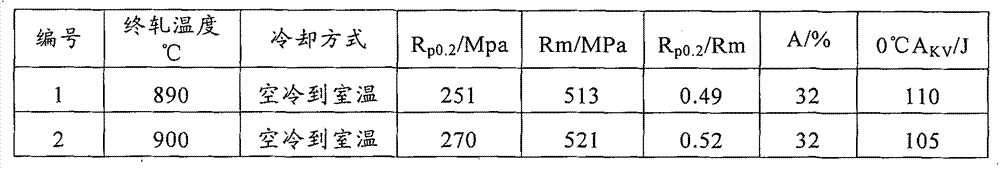

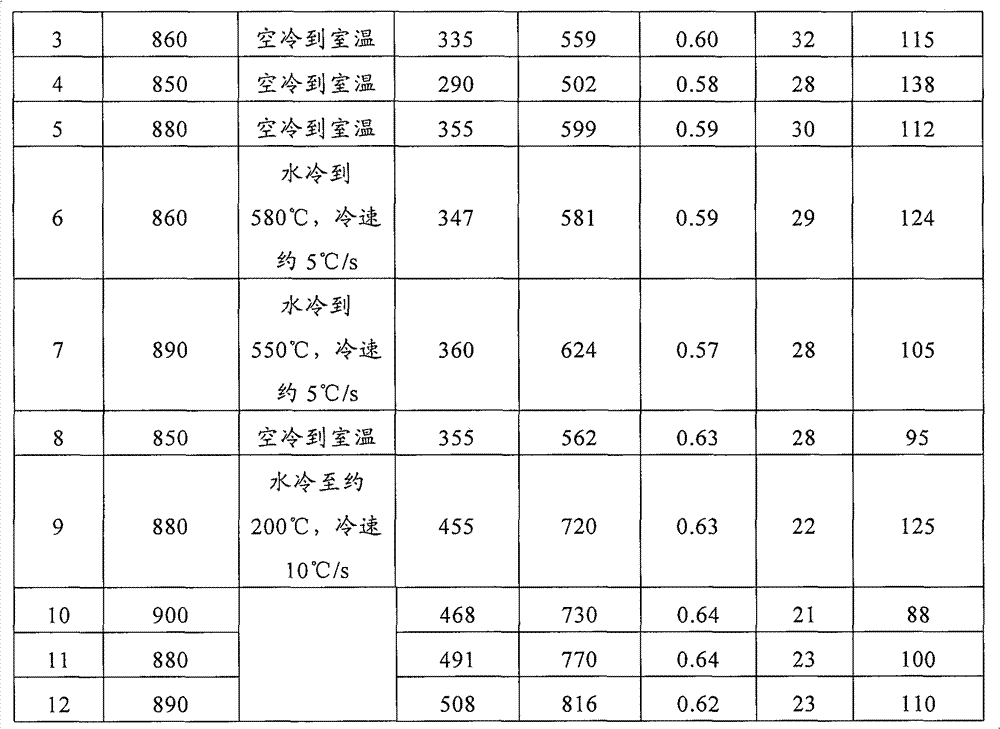

[0043] Specifically, according to the steel composition requirements of the present invention, seven batches of the steel of the present invention were smelted in a vacuum induction furnace, the steel ingot was heated at a temperature of 1180±10° C., the holding time was 3 hours, and the thickness of the finish rolling was three times the final thickness of 60 mm. The rolling temperature is 860-900°C. After final rolling, it is air-cooled to room temperature, or cooled to room temperature at a cooling rate of 5-15°C / s. Example The steel plate was rolled 7 times in total, and the final thickness of the steel plate was 20mm.

[0044] The chemical compositions of the examples of the present invention are shown in Table 1.

[0045] Table 1

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com