Attaching mechanism and ejecting method for super high-rise construction elevator

A technology for construction elevators and super high-rises, which is applied to elevators, elevators, transportation and packaging in buildings. It can solve the problems of inconvenient disassembly of attached walls, and achieve the effect of improving installation efficiency and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

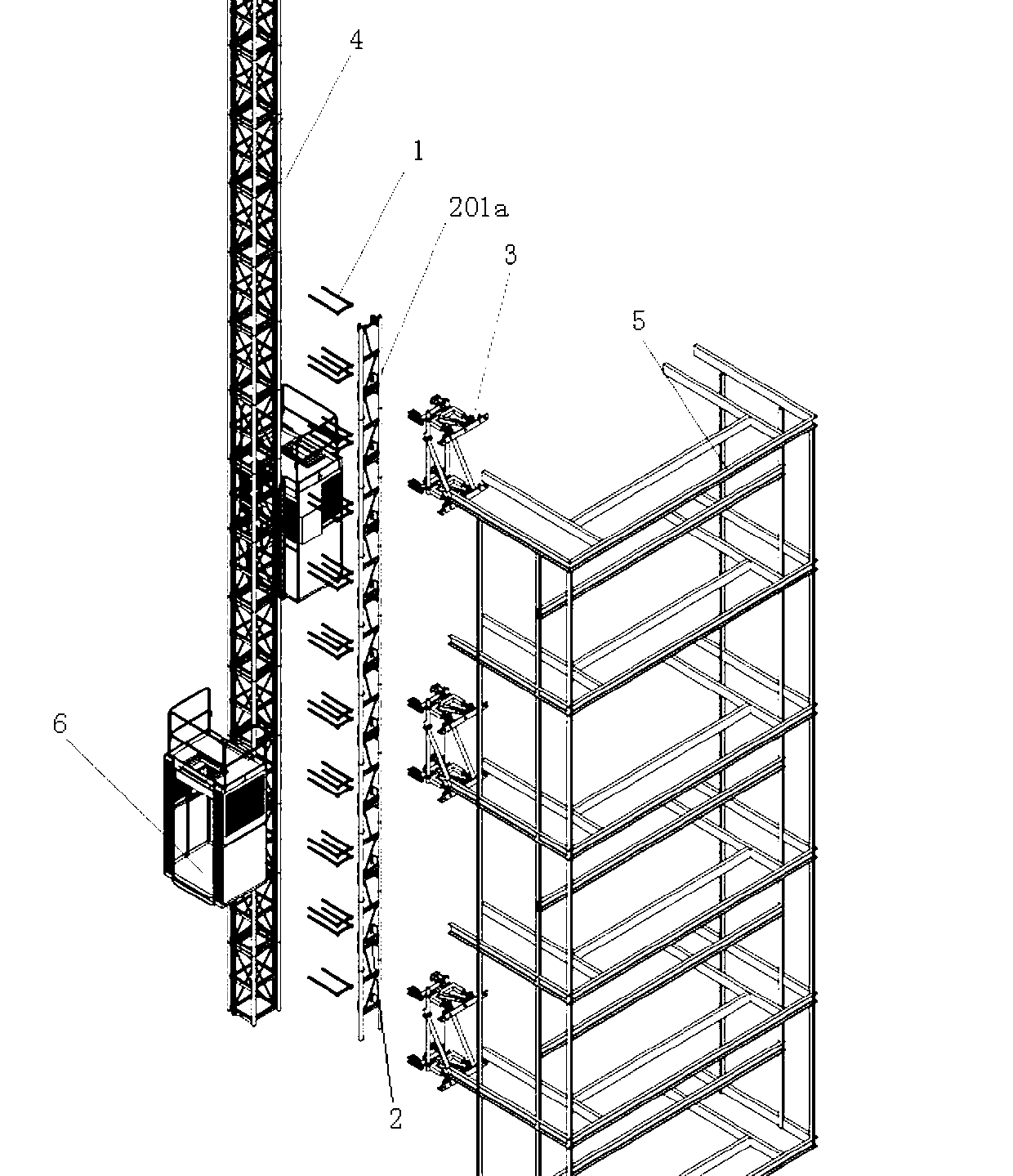

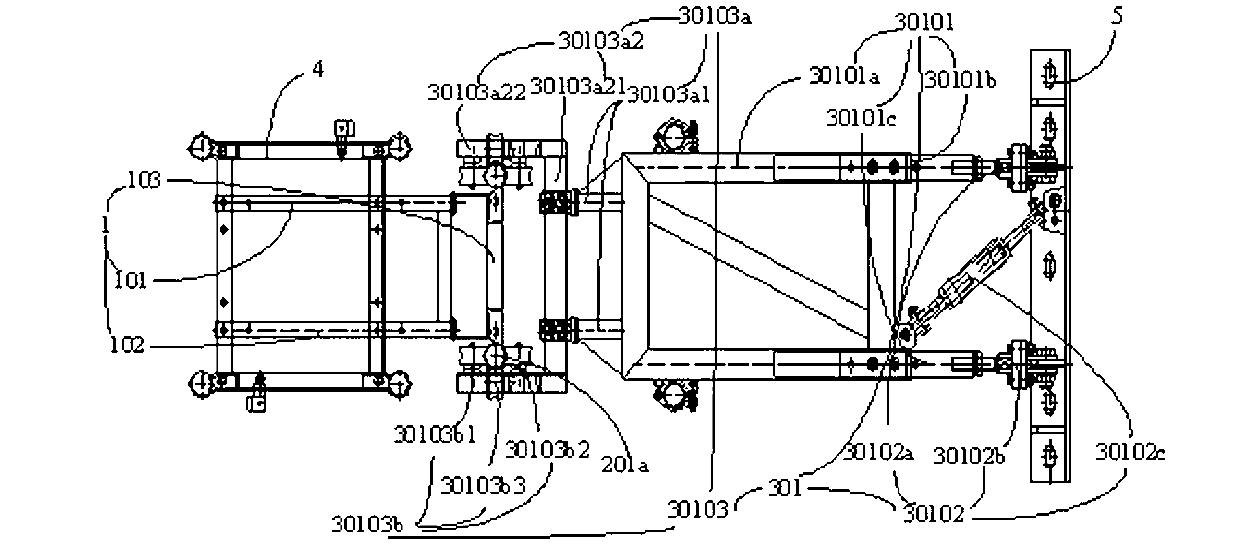

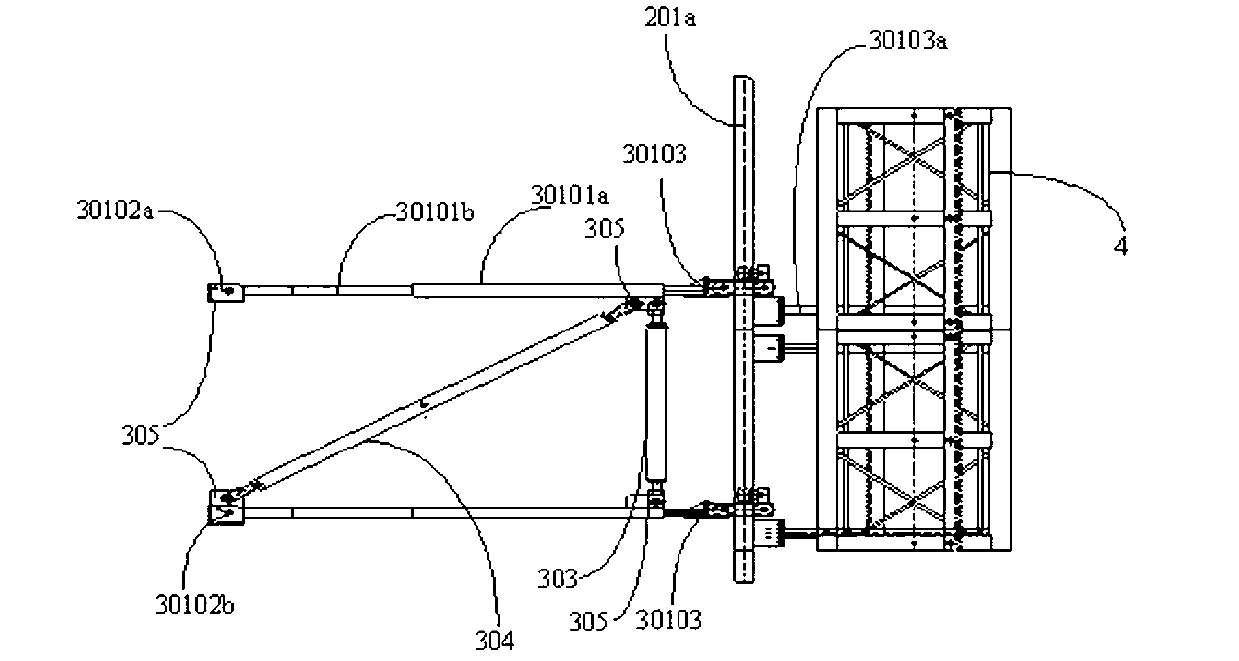

[0025] Please also refer to figure 1 , the present invention provides an attachment mechanism for a super high-rise construction elevator, which is applied in the top formwork system, and includes a wall attachment 1, a guide rail assembly 2 and a rolling assembly 3, one end of the attachment wall attachment 1 is fixedly connected to the elevator standard section 4, and the other One end is fixed with the guide rail part 2 by bolts; one end of the rolling part 3 is fixedly connected with the inner frame of the jacking formwork 5 by bolts, and the other end is rollingly connected with the guide rail part 2; wherein, when the jacking formwork 5 is jacked up, The wall attachment 1 and the guide rail member 2 are fixed, and the rolling member 3 rolls on the guide rail member 2 and is lifted together with the jacking formwork 5 .

[0026] Specifically, the guide rail part 2 is an assembly composed of a section of guide rail standard sections 201, and the guide rail standard section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com