Hole-cleaning method for washing pile hole and pumping sand

A pile hole and hole bottom technology, which is applied in wellbore flushing, earthwork drilling, wellbore/well components, etc., can solve the problems of high investment in equipment, slow pile hole cleaning speed, and large amount of mud drilling slag transported outside , to achieve the effects of ensuring construction quality, saving construction costs, and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

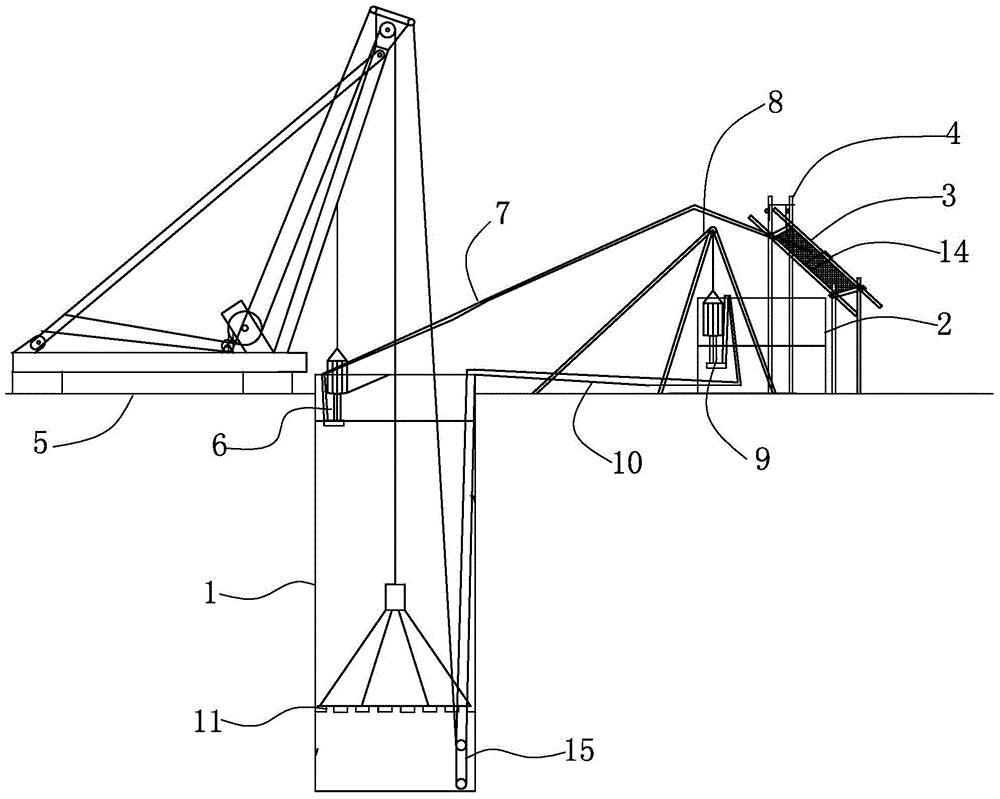

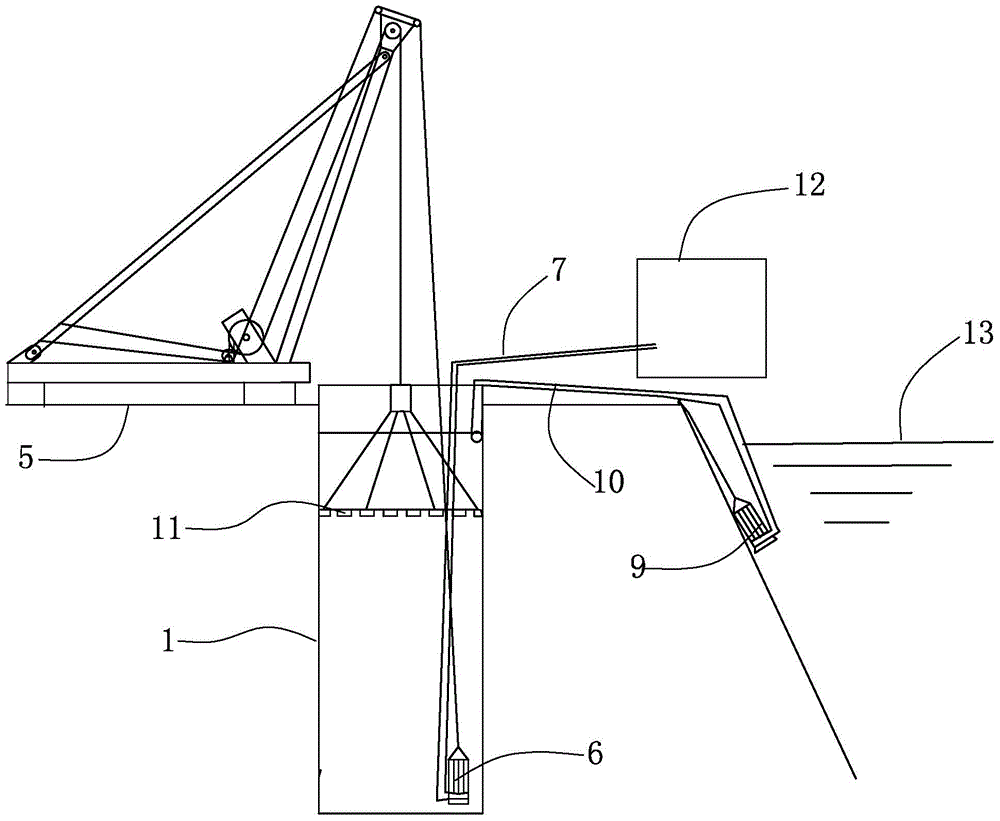

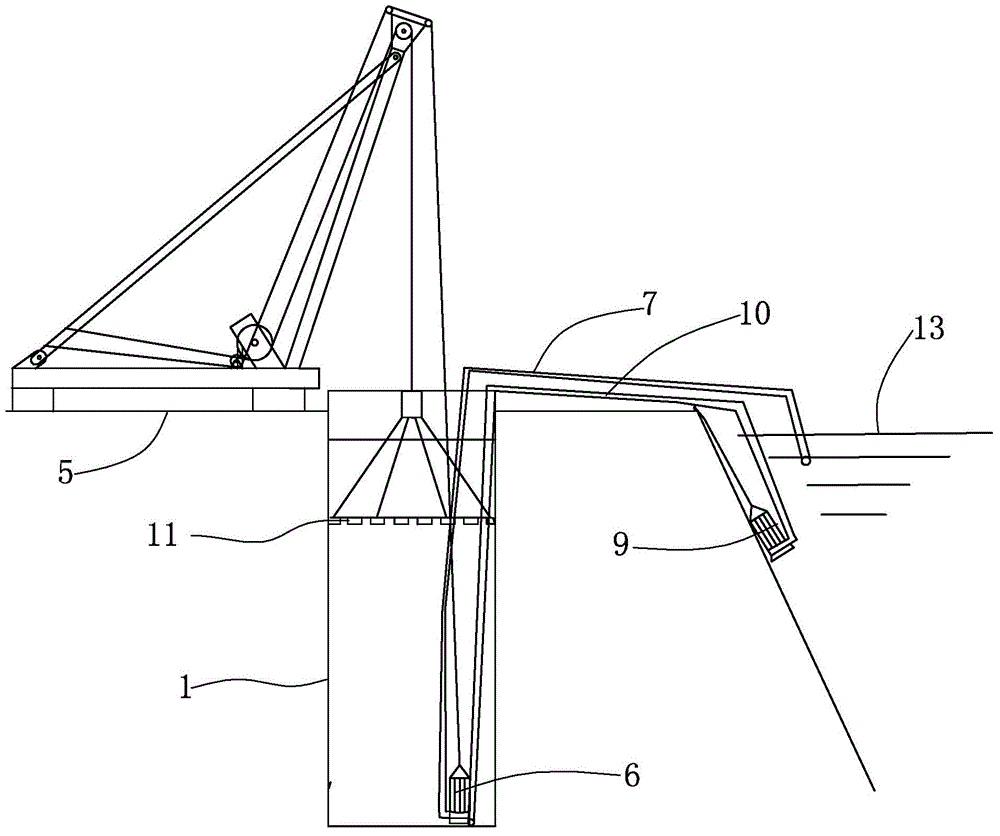

[0018] After the pile hole is formed, the pile hole needs to be drilled before pouring concrete. The hole drilling process includes sand screening, slurry pumping, and washing. Such as figure 1 , figure 2 , image 3 As shown, the implementation steps of the present invention are as follows:

[0019] (1) A mud cylinder 2 for storing mud is set near the pile hole 1, and a filter screen 3 is set above the mud cylinder 2, and the filter screen 3 is fixed on a filter screen bracket 4, and one end of the filter screen is higher. Low-inclined setting, and the edge of the lower end of the filter screen 3 is located outside the edge of the mud cylinder 2;

[0020] (2) A slurry suction pump 6 is suspended on the handlebar of the percussion drill 5 by a chain hoist, the slurry suction pump 6 is suspended in the pile hole 1, and the slurry suction pump 6 is connected to a slurry outlet pipe 7;

[0021] (3) A tripod 8 is provided on one side of the mud cylinder 2, a slurry pump 9 is suspended...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com