Construction method for haunching bi-directional tension prestressed concrete complex beam-column joints

A technology of beam-column joints and construction methods, which is applied in the direction of architecture and building construction, can solve the problems of difficult construction quality guarantee, intricate distribution, and complicated construction technology in the core area of beam-column joints, so as to ensure that the joint domain The effect of bearing capacity, speeding up the construction progress and ensuring the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

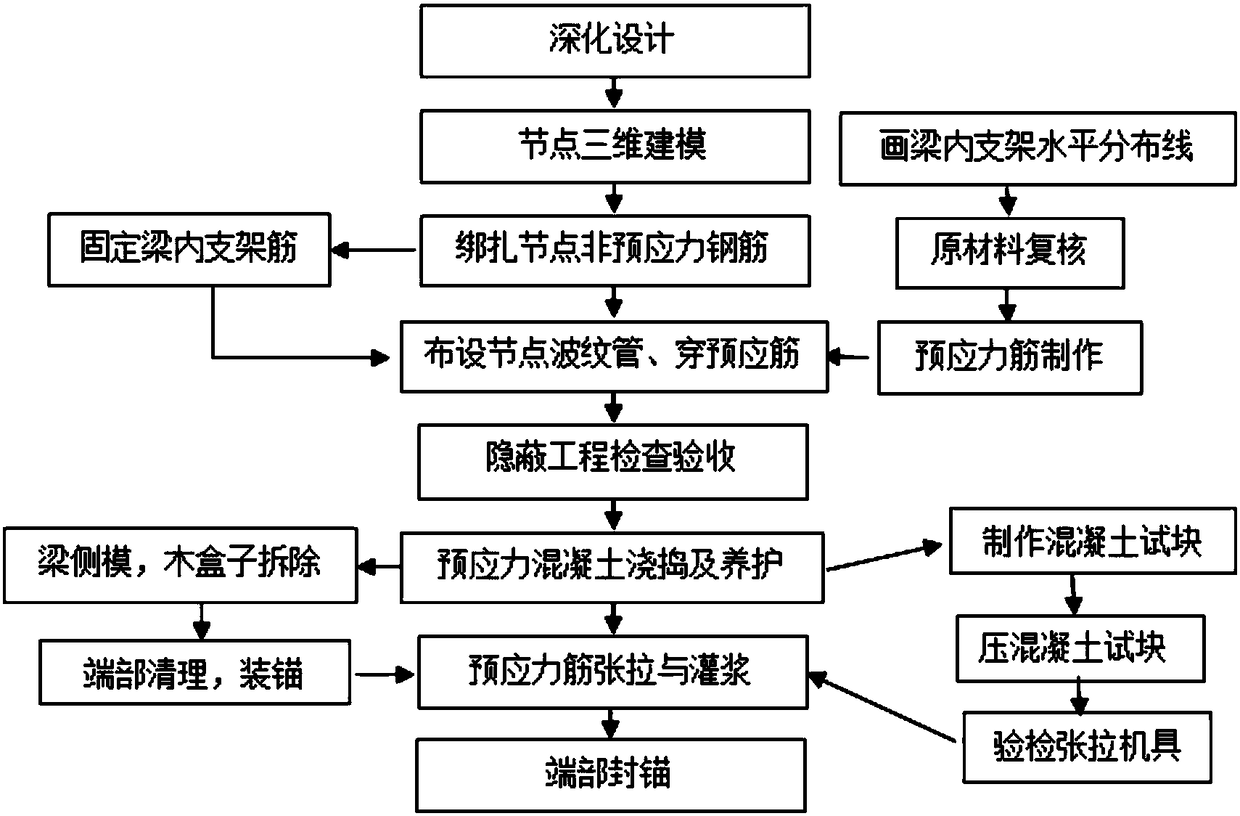

[0036] This embodiment discloses a construction method for complex beam-column joints of bidirectionally tensioned prestressed concrete with haunches, see figure 1 , including the following steps:

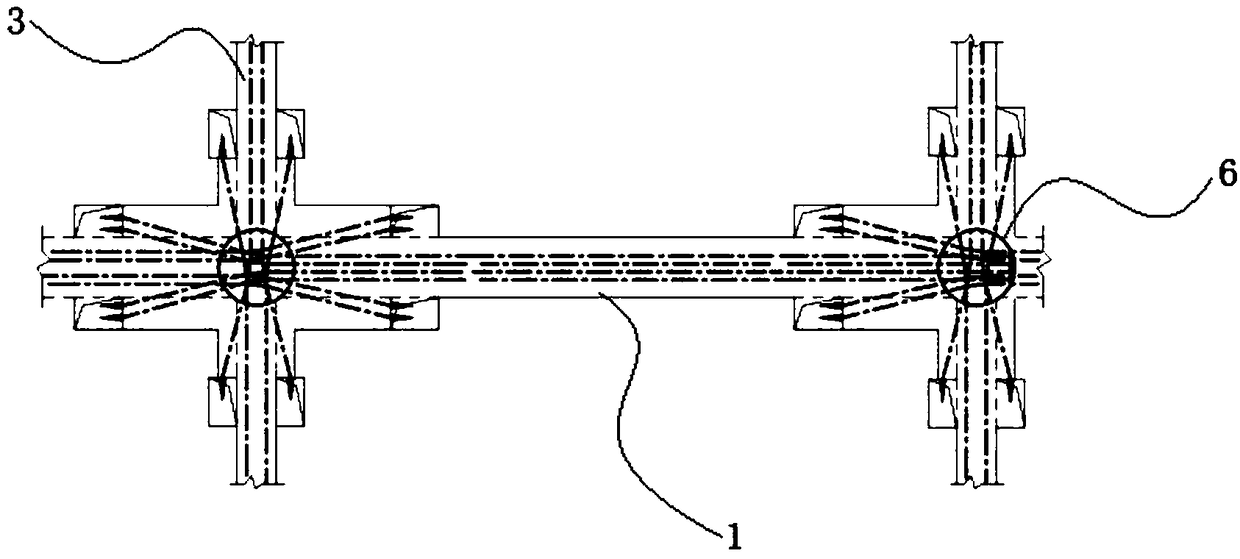

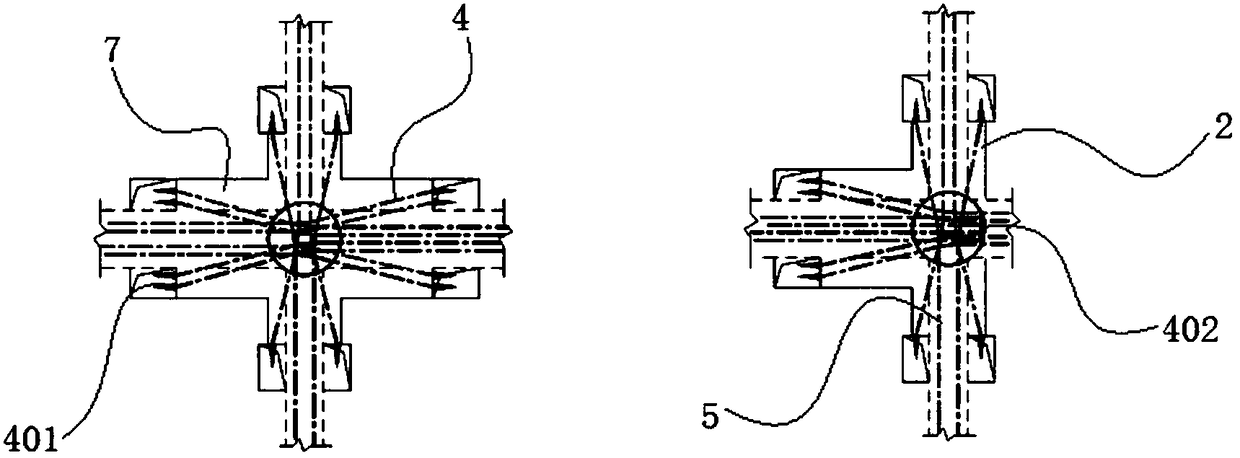

[0037] 1) Deepen the design of the frame beam, and determine the form of beam side addition and the sagittal shape of the prestressed tendons in the frame beam. see figure 2 , in this embodiment, the beam-column joint includes a column 6 and a frame beam I1 and a frame beam II3 connected to the column 6 . The frame beam I1 and the frame beam II3 are cross-connected on the node area in a cross shape. The frame beam II3 is horizontally haunched from the column edge of the beam-column joint to form the haunch I2. The axillation forms of the axillation I2 and the axillation II7 are both horizontal rectangular axillations. Tension anchors are buried at the ends of the added haunches I2 and II7. see image 3 , the prestressed tendon I4 is arranged in the frame beam I1, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com