Method for realizing seepage prevention of bridge wall by means of polyvinyl chloride film

A technology of polyvinyl chloride membrane and dam wall, which is applied in the direction of dams, barrages, weirs, etc., to achieve the effects of reducing land acquisition and resettlement, saving construction period and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

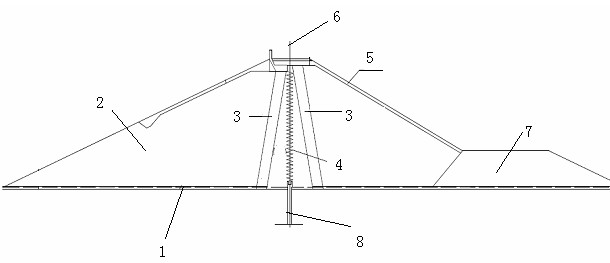

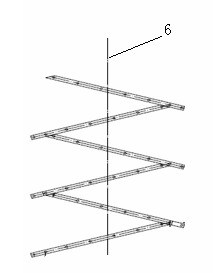

[0020] The method for carrying out anti-seepage of dam wall with polyvinyl chloride film of the present invention is to adopt polyvinyl chloride film, place the center of dam core wall and carry out anti-seepage, the formation of anti-seepage dam wall is: the bottom of the dam is a sand cushion 1, and the middle is The polyvinyl chloride membrane cut-off wall 2, the two concrete cut-off walls are the transition material layer 3, the outside of the transition material layer is the dam shell 2, and the surface of the dam shell is stone masonry slope protection 5, such as figure 1 shown. The arrangement of the PVC membrane in the PVC membrane cut-off wall is folded and raised in a zigzag in the vertical direction, such as Figure 4 shown.

[0021] The construction method of concrete cut-off wall is as follows:

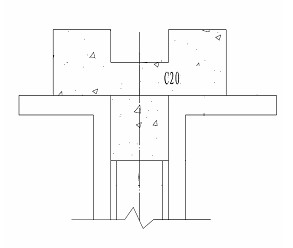

[0022] 1) Treatment of the head 8 of the anti-seepage wall of the polyvinyl chloride membrane: the head of the anti-seepage wall is the weak point of the pouring quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com