Hydraulic system for adjustment of level posture of hard-rock heading machine

A hard rock roadheader and horizontal posture technology, which is applied in fluid pressure actuation system testing, mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as damage to mechanical components, large impact of load pressure fluctuations, and tunnel deviation from the predetermined track. , to speed up the construction progress and improve the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

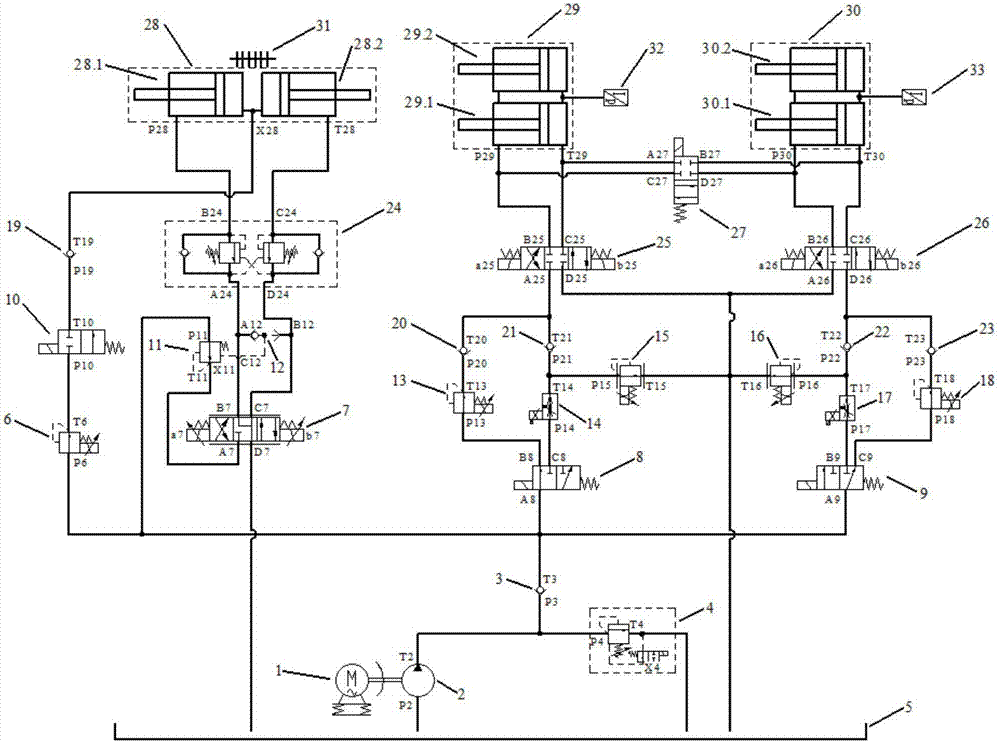

[0015] Such as figure 1As shown, the present invention includes a motor 1, a high-pressure pump 2, an electromagnetic unloading valve 4, a first check valve 3, a second check valve 19, a third check valve 20, a fourth check valve 21, and a fifth check valve. One-way valve 22, sixth one-way valve 23, first proportional pressure reducing valve 6, second proportional pressure reducing valve 13, third proportional pressure reducing valve 18, three-position four-way electromagnetic proportional reversing valve 7, first two One-position three-way electromagnetic reversing valve 8, second two-position three-way electromagnetic reversing valve 9, two-position two-way electromagnetic reversing valve 10, differential pressure reducing valve 11, shuttle valve 12, first speed regulating valve 14, second Two speed regulating valves 17, the first proportional relief...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com