High-rise building garbage transportation system

A technology for transportation systems and high-rise buildings, applied in the directions of buildings, building components, building structures, etc., can solve the problems of increased costs, reduced working surfaces, and excessive construction sections of facades, so as to save costs and improve construction. Efficiency, the effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

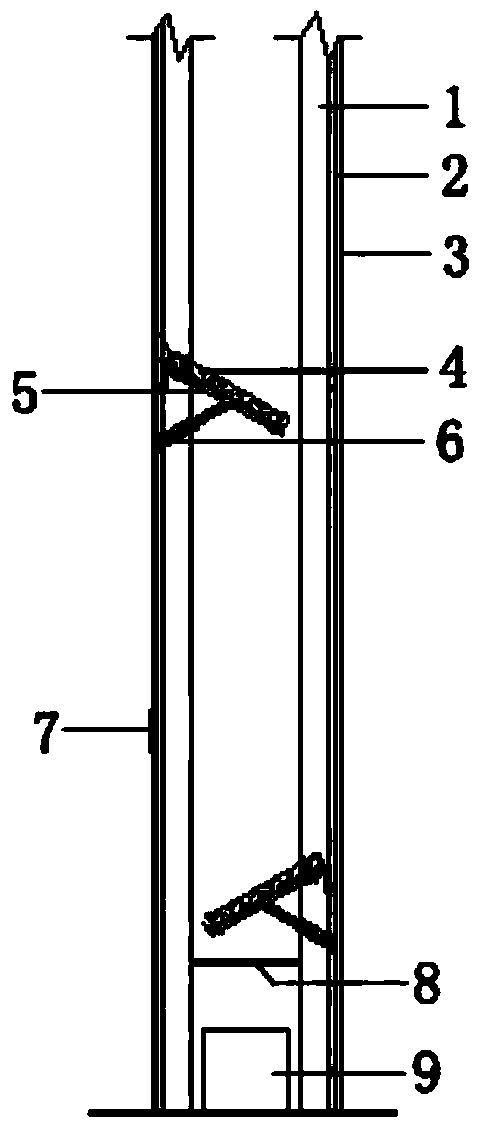

[0020] As shown in the figure, a high-rise building waste transportation system includes a special garbage bin arranged in the vertical opening of the core tube of the tower; it also includes an energy reduction device arranged on the inner wall of the special garbage bin, and a weight limiting device 8 arranged at the bottom of the special garbage bin And the garbage sorting and recycling device installed at the garbage outlet on the first floor.

[0021] The energy-reducing device is a spring plate, and its structure is divided into three parts, the upper surface layer is a tire 4, the lower surface layer is a steel plate a5, and the bottom is a profiled spring 6. The tire 4 is a waste tire. The total length of the spring 6 is 210mm, the outer diameter is 25mm, the material is piano wire, and the total number of coils is 20.

[0022] There are four bolt connections between the tire 4 and the steel plate a5.

[0023] The steel plate a5 is a checkered steel plate.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com