Keel for dry hanging stone curtain wall and mounting method of keel

A technology of dry-hanging stone materials and installation methods, which is applied to the processing of building materials, walls, building components, etc., can solve the problems of high-altitude operations and high-altitude electric welding operations, etc., to reduce safety hazards, shorten construction periods, and improve The effect of installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

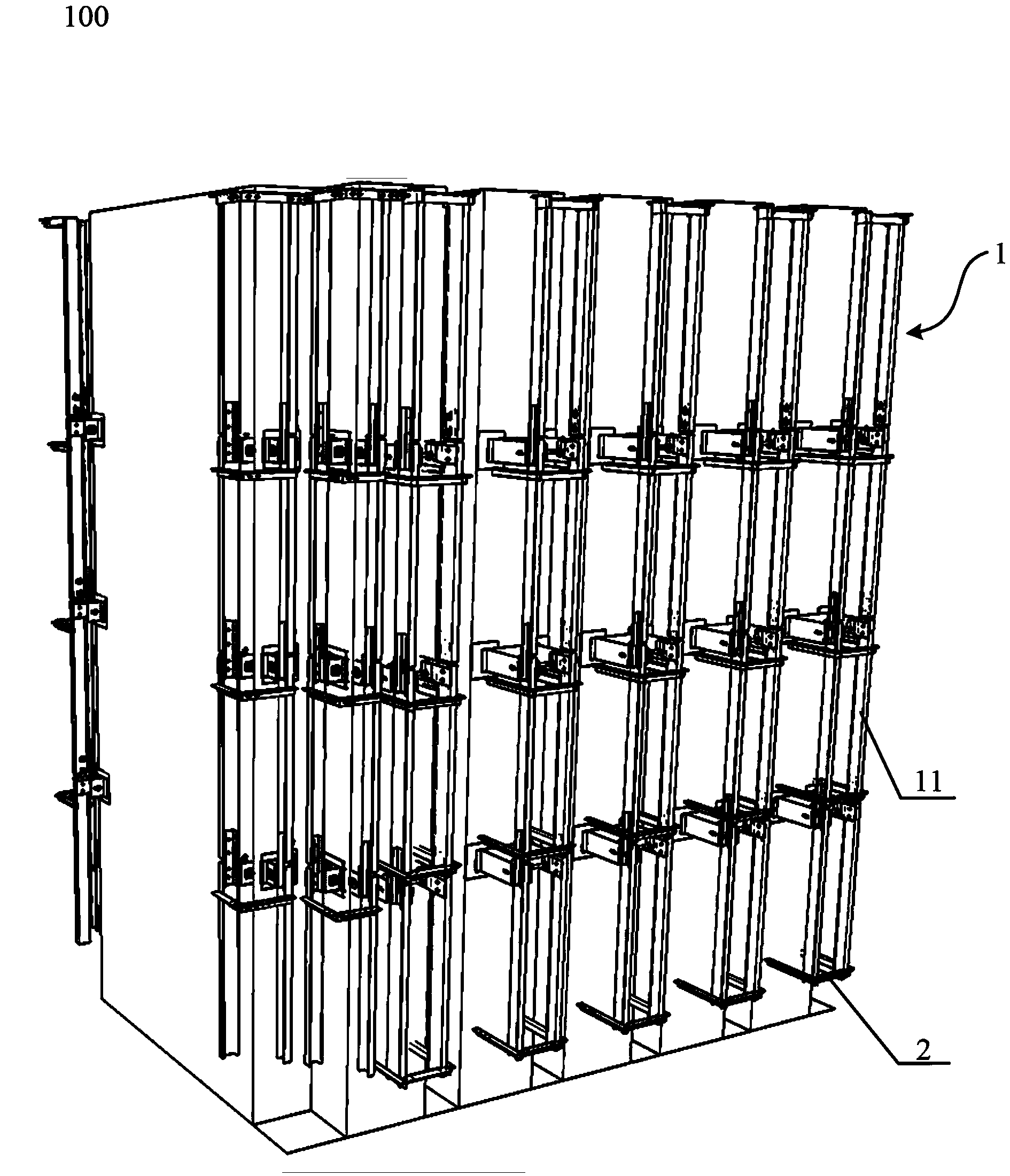

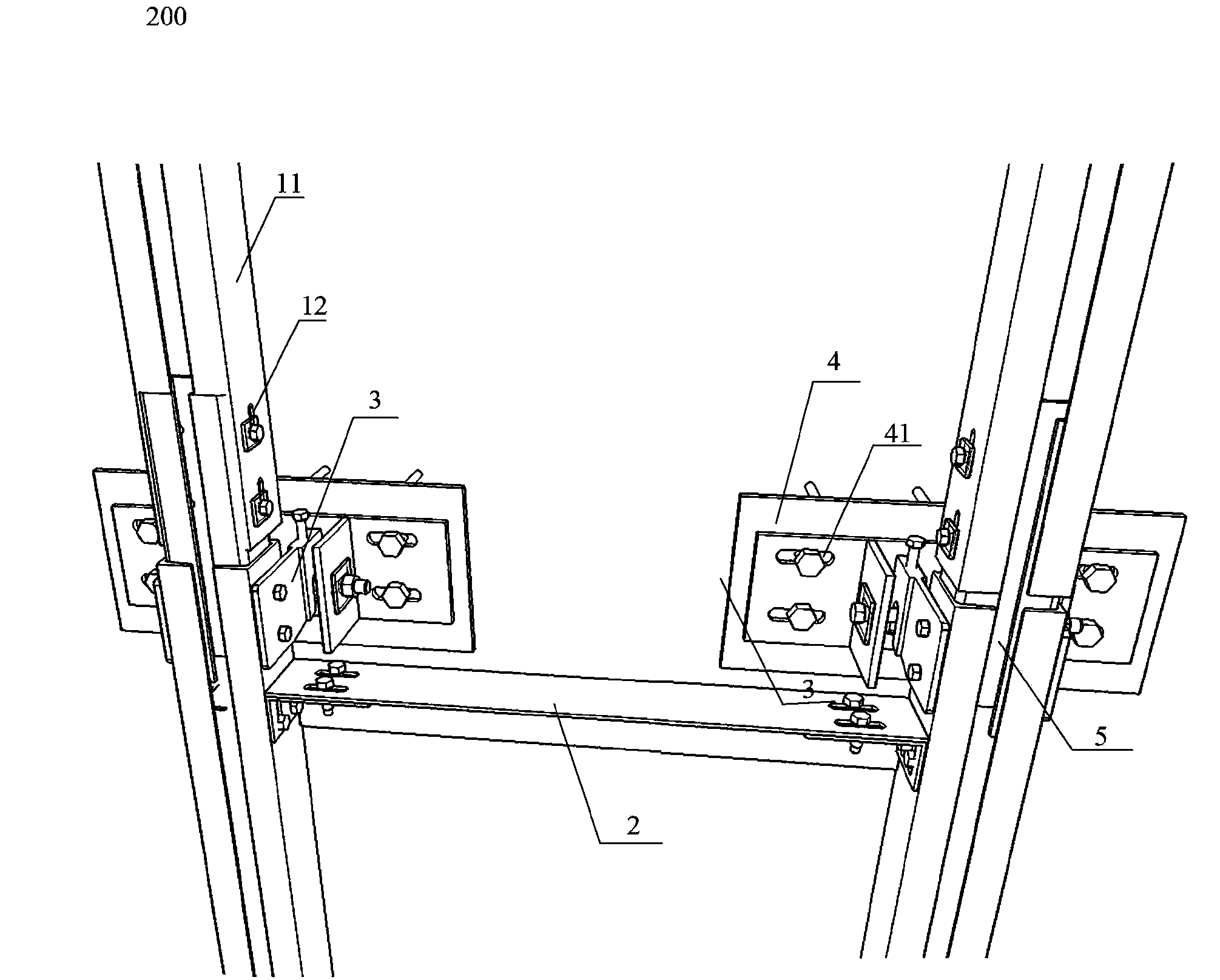

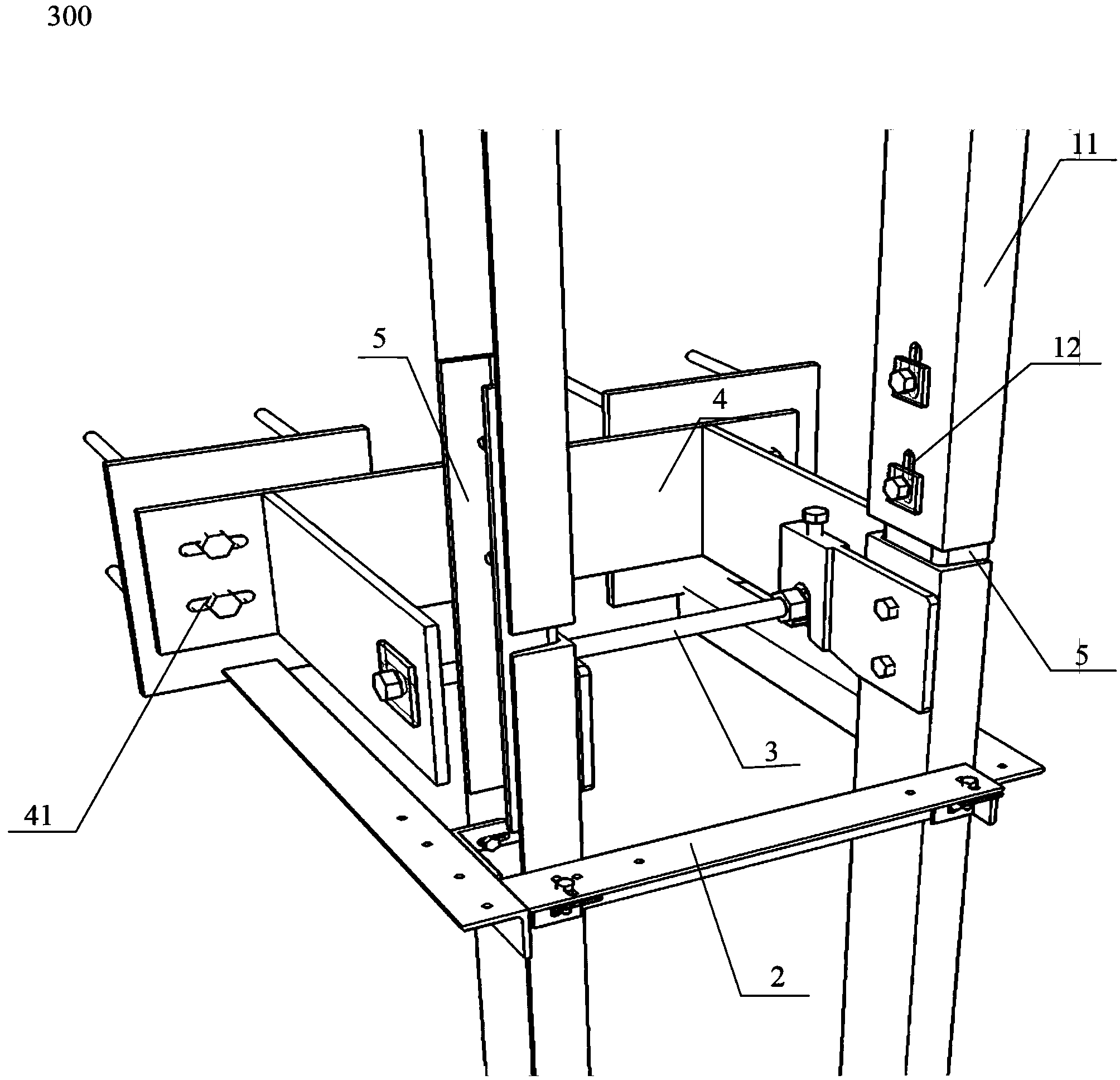

[0067] Such as figure 1 As shown, the keel 100 for dry-hanging stone curtain wall of this embodiment includes several steel frame units 1 and several dry-hanging connectors 2, and the steel frame units 1 and the dry-hanging connectors 2 are all manufactured in the factory, Each steel frame unit 1 includes at least one channel steel 11 , and the dry-hanging connector 2 spans between adjacent channel steels 11 and is fixedly connected to the channel steel 11 .

[0068] The steel frame unit 1 is prefabricated according to the actual situation of the wall to be decorated, and several steel frame units 1 and dry-hanging connectors 2 can be prefabricated according to the actual situation of the wall to be decorated. Specifically, the wall to be decorated can be divided into several planes, columns and corners.

[0069] For the plane situation, the steel frame unit 1 can only use one channel steel 11, which can make the transportation of various components from the factory to the co...

Embodiment 2

[0080] This embodiment provides a method for installing the keel of the dry-hanging stone curtain wall in the first embodiment. Image 6 It is the flow chart of the installation method for the keel of the dry hanging stone curtain wall of the present embodiment, Figure 7 It is a construction schematic diagram of the installation method for the keel of the dry-hanging stone curtain wall according to the second embodiment of the present invention. Combine below Image 6 with Figure 7Describe in detail the installation method for the keel of the dry-hanging stone curtain wall of this embodiment, including the following steps:

[0081] Step 1: Prepare several steel frame units, the dry-hanging connectors, the transverse anchors and the sleeve cores according to the predetermined requirements in the factory;

[0082] Specifically, it is first necessary to measure and analyze the wall to be decorated, calculate the quantity and shape of the required dry-hanging stone according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com