Method for reinforcing assembly type multilayer brick-concrete structure

A multi-layer brick and prefabricated technology, which is applied in building construction, protective buildings/shelters, and building maintenance, can solve problems such as complex construction procedures, long construction periods, and many wet operations, and achieve shortened construction periods and improved engineering quality. The effect of reducing the quantity and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

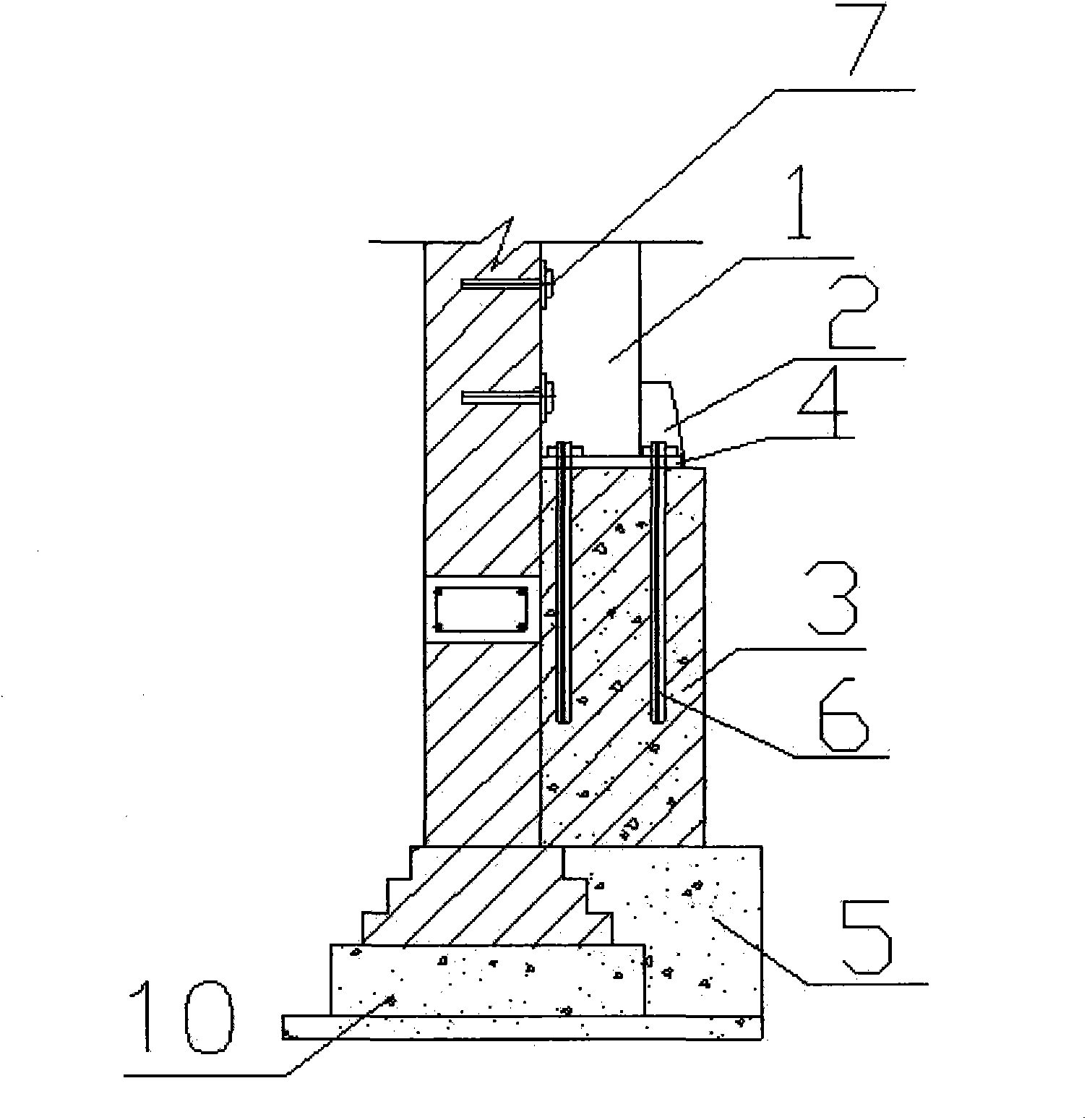

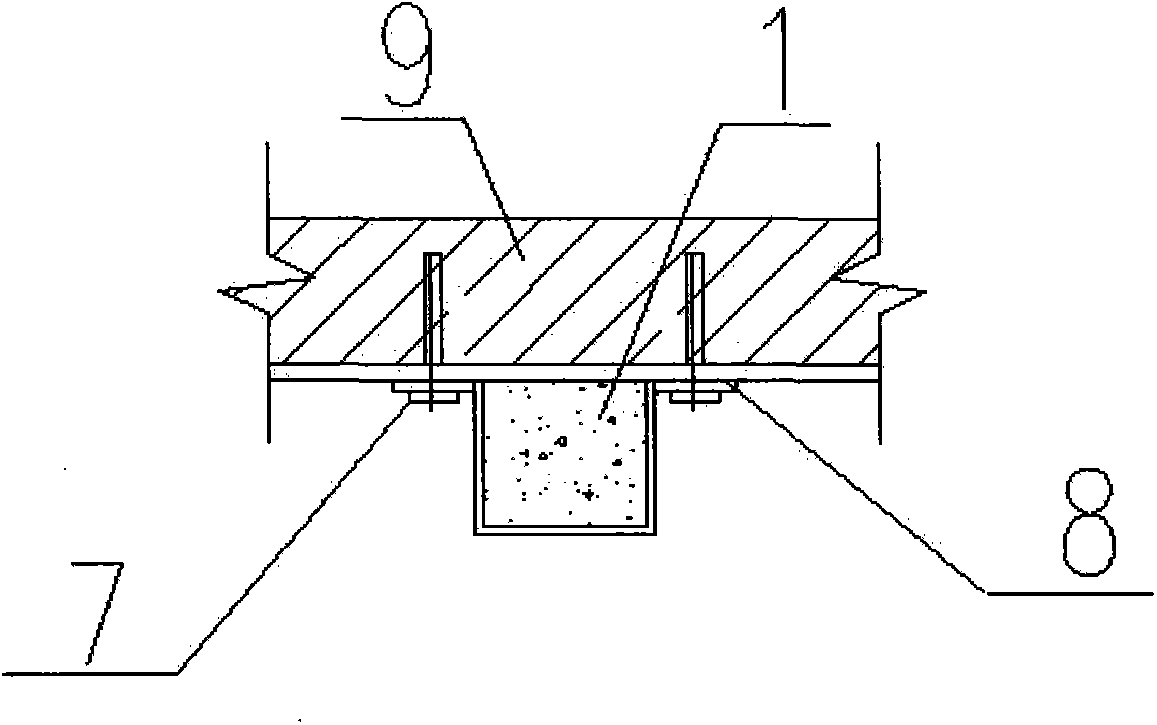

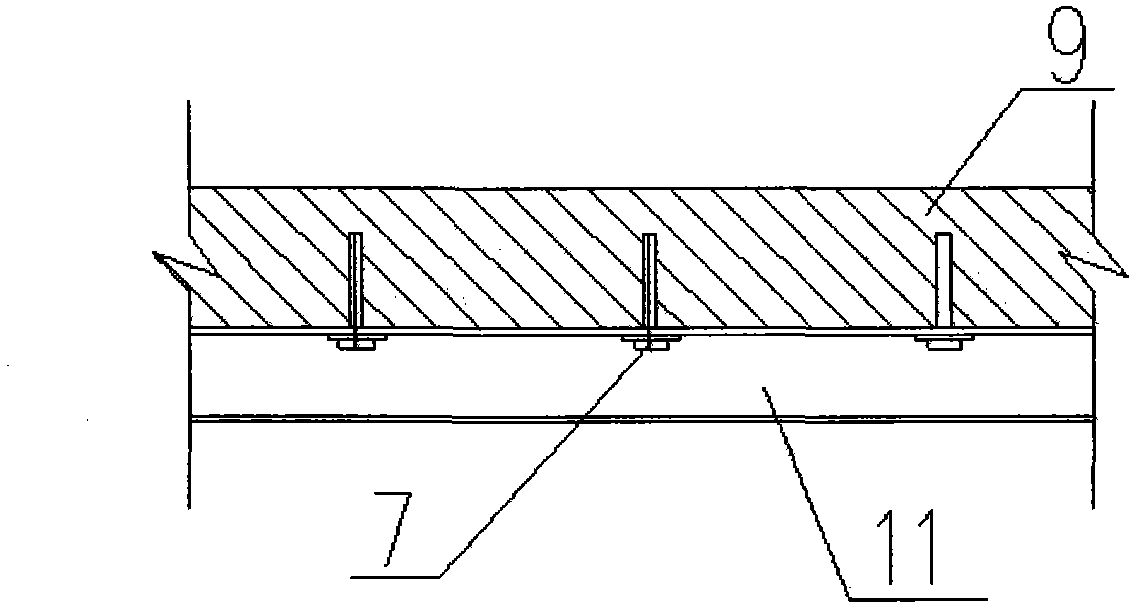

[0025] Such as Figure 1-5 Shown, a kind of prefabricated multilayer brick-concrete structure reinforcement method of the present invention, its specific implementation is as follows:

[0026] Including the original multi-storey brick-concrete structure, it also includes square steel concrete structural columns 1, channel steel ring beams 11 and flat steel tie rods. At the intersection of the walls, the lower part of the square steel concrete structural column 1 is provided with a structural column foundation. The structural column foundation includes the lower concrete base 5 and the upper cast-in-place concrete column pier 3. The concrete base 5 is connected with the original foundation 10 of the original multi-storey brick-concrete structure through the 4 bolt connections of the bottom plate of the structural column; The channel steel ring beams 11 are connected together by bolts of an additional partition support beam 12; prestressed flat steel tie rods are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com