Compound early strength agent for cold-recycling of emulsified asphalt and preparation method and application of compound early strength agent

A technology of compounding early strength agent and emulsified asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of low early strength of emulsified asphalt cold regeneration, shorten the construction period, simple technology, and is conducive to popularization and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of EA502 cold recycled emulsified asphalt:

[0033] According to the preparation method of the emulsified asphalt in the content of the invention, the asphalt is selected from No. 70 road petroleum asphalt (Korean Ssangyong), and the emulsifier is selected from Runqiang-EA502 slow-cracking cold regeneration emulsifier (Jiangsu Subote New Material Co., Ltd.)

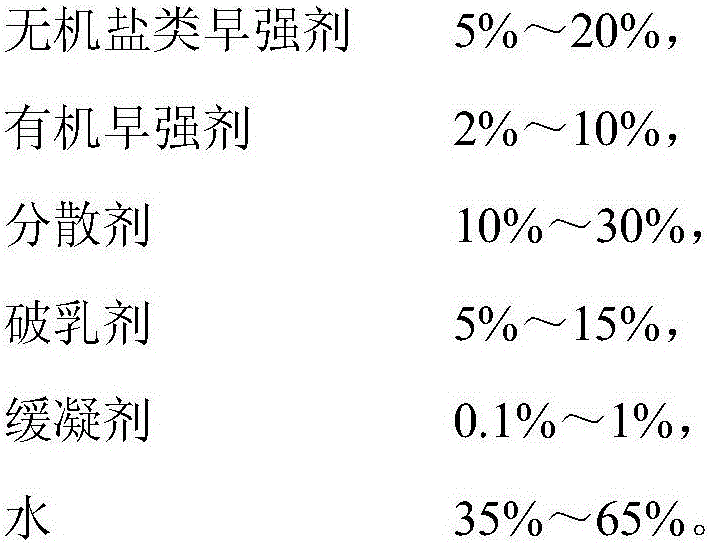

[0034] (2) The preparation of composite accelerator is as follows:

[0035] Weigh 7 parts of calcium chloride and 6 parts of sodium nitrate and dissolve them in 50 parts of water, then add 3 parts of diethanolamine, 2.5 parts of triethanolamine, 7 parts of sodium lignosulfonate water reducer, and 11 parts of polycarboxylate water reducer , 6 parts of alkylphenolic resin polyoxyethylene polyoxypropylene ether, 7 parts of polysiloxane polyoxyethylene polyoxypropylene ether and 0.5 part of sugar are stirred by suitable stirring equipment to obtain a uniform composite early strength agent solution;

[...

Embodiment 2

[0053] (1) The preparation of EA502 cold recycled emulsified asphalt is as follows:

[0054] EA502 cold regenerated emulsified asphalt is consistent with Example 1.

[0055] (2) The preparation of composite accelerator is as follows:

[0056] The preparation of the composite accelerator is consistent with that in Example 1.

[0057] (3) The preparation of compound early strength agent (early strength type) EA502 emulsified asphalt cold recycled mixture is as follows:

[0058] In addition to replacing the old milling and planing asphalt mixture of the Beijing-Taiwan Expressway He-Beng section overhaul project with the milling and planing old material of the Jiangxi Changtai Expressway Reconstruction and Expansion Project, other preparation methods, materials and steps are the same as those in Example 1. Early-strength EA502 emulsified asphalt cold regeneration The mix is prepared consistently.

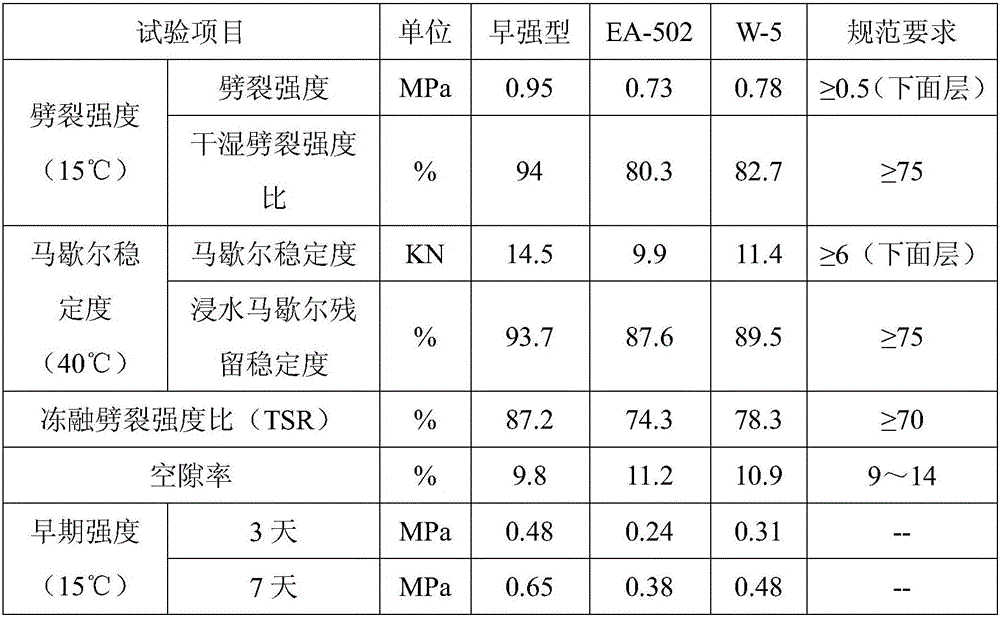

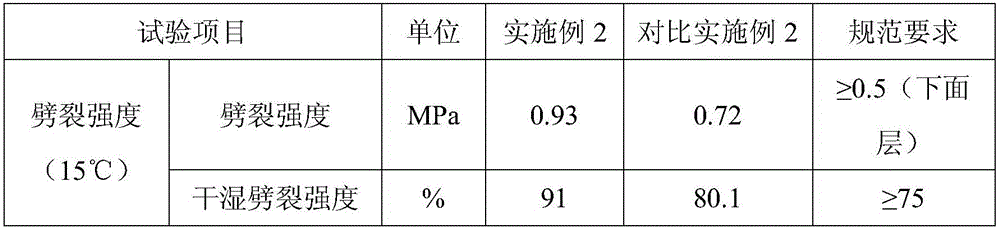

[0059] The properties of the early-strength EA502 emulsified asphalt cold recy...

Embodiment 3

[0071] (1) Preparation of EA502 cold recycled emulsified asphalt:

[0072] EA502 cold regenerated emulsified asphalt is consistent with Example 1.

[0073] (2) The preparation of composite accelerator is as follows:

[0074] Weigh 4 parts of calcium chloride, 3 parts of sodium sulfate and 6 parts of sodium nitrite and dissolve them in 50 parts of water, then add 3 parts of ethylene glycol, 2.5 parts of triethanolamine, 13 parts of acetone water reducer, and 5 parts of sulfamic acid Salt superplasticizer, 5 parts of high molecular weight polyoxyethylene polyoxypropylene ether, 8 parts of sodium sulfonate, 0.2 part of sodium sugar, 0.2 part of trisodium phosphate and 0.1 part of glycerol, stirred with suitable stirring equipment to obtain a uniform compound early strength agent solution;

[0075] (3) Adding compound early strength agent (early strength type) EA502 emulsified asphalt cold recycled mixture is prepared as follows:

[0076] Except for the change of the compound e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com