Adhesive composition for optical components, adhesive for optical components, optical component with adhesive layer, and image display device

A technology for optical components and adhesive layers, applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of uneven color, light leakage, etc., and achieve difficult foaming and color suppression Excellent effect of non-uniformity and reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

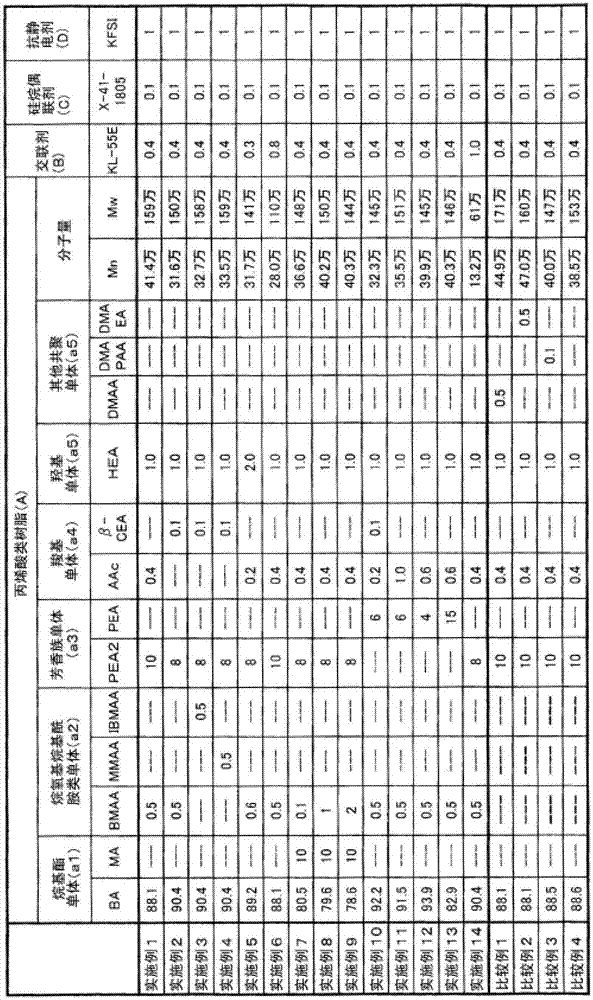

[0135]For Example 14, put 120 parts of ethyl acetate into a four-necked round-bottomed flask equipped with a reflux condenser, a stirrer, a nitrogen blowing port, and a thermometer, and heat up while stirring. When the internal temperature reaches 75°C, 0.05 parts of azobis Add all the solution of isobutyronitrile (polymerization initiator) dissolved in 5 parts of ethyl acetate, then keep the internal temperature at 74-76°C, add 90.4 parts of butyl acrylate (a1), 8 parts of phenoxydiethyl A mixed solution of diol acrylate (a3), 1 part of 2-hydroxyethyl acrylate (a5), 0.5 part of N-(n-butoxymethyl) acrylamide (a2), and 0.4 part of acrylic acid (a4) was passed through 2 It was added dropwise to the reaction system within hours. Then, after carrying out superposition|polymerization at internal temperature 74-76 degreeC for 5 hours, ethyl acetate was added, and an acrylic resin (A) solution was obtained.

[0136] In addition, for Comparative Examples 1 to 3, other copolymerizable...

Embodiment 1~14、 comparative example 1~4

[0161] The respective compounding components prepared and prepared as described above were compounded at the ratios shown in Table 1 to prepare an adhesive composition to be an adhesive-forming material for optical parts, which was diluted with methyl ethyl ketone (viscosity [500 ~1000mPa·s (25°C)]) to prepare an adhesive composition solution.

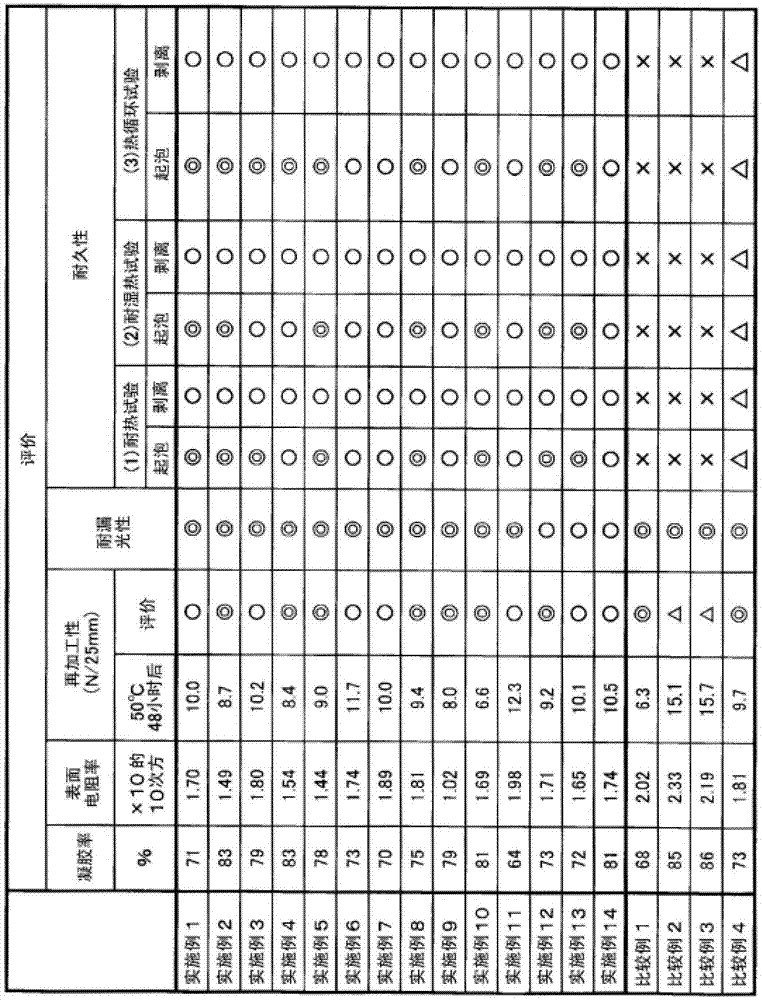

[0162] Next, the above-mentioned adhesive composition solution was coated on a polyester-based release sheet so that the thickness after drying was 25 μm, and after drying at 90° C. for 3 minutes, the side of the formed adhesive composition layer was transferred to After coating on a polyethylene terephthalate (PET) film (thickness 38 μm), it was cured for 10 days at a temperature of 23° C. and a relative humidity of 65% to obtain a PET film with an adhesive layer.

[0163] Using the PET film with an adhesive layer obtained in this way, the gel fraction and surface resistivity were measured and evaluated by various methods shown below....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com