In-wheel motor drive device

A technology of in-wheel motor and driving device, which is applied in the directions of gear transmission, electromechanical device, electric device, etc., can solve the problems of decreased durability and lubricating performance of the in-wheel motor driving device 101, and achieve excellent durability and restrain temperature rise. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

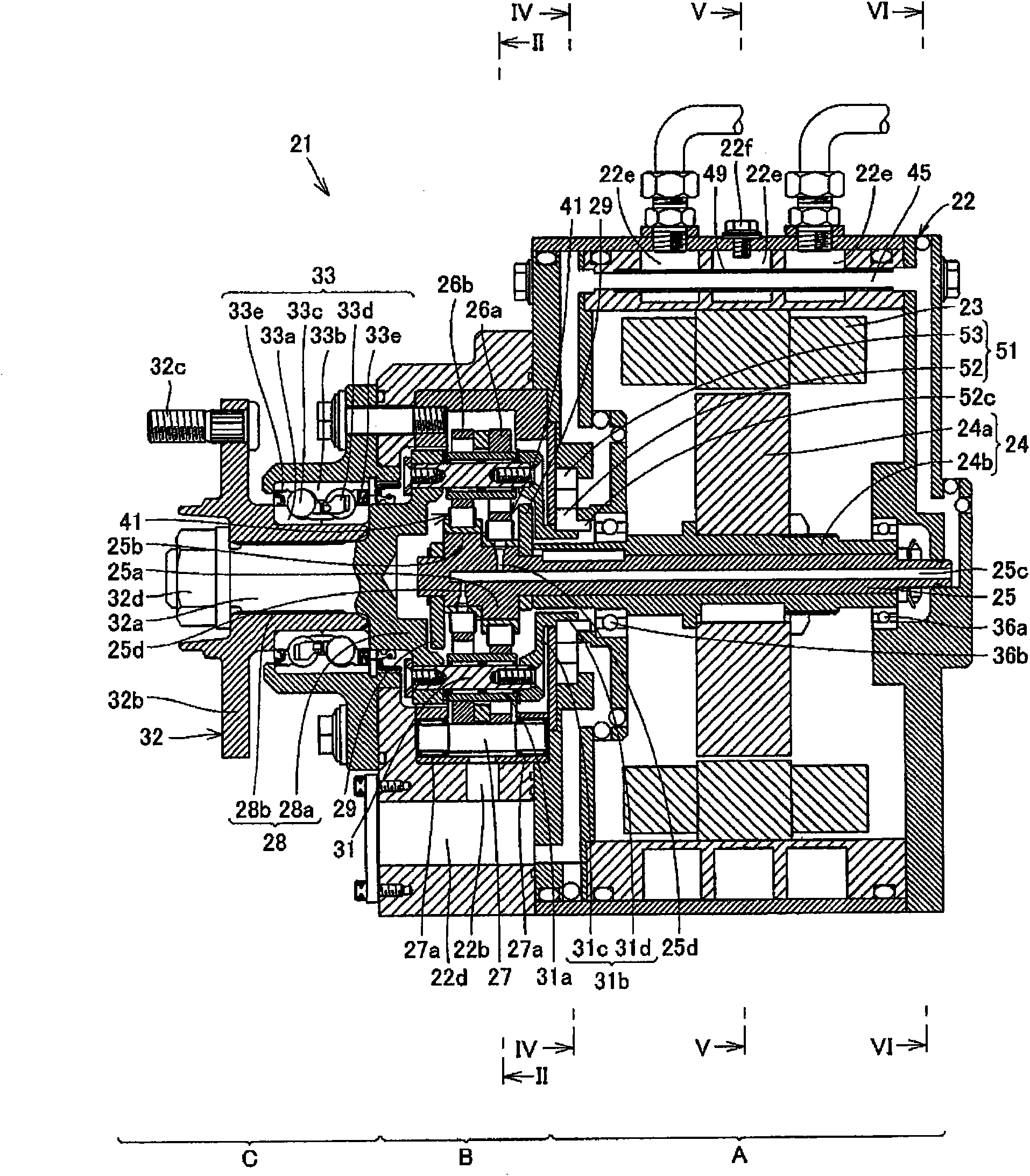

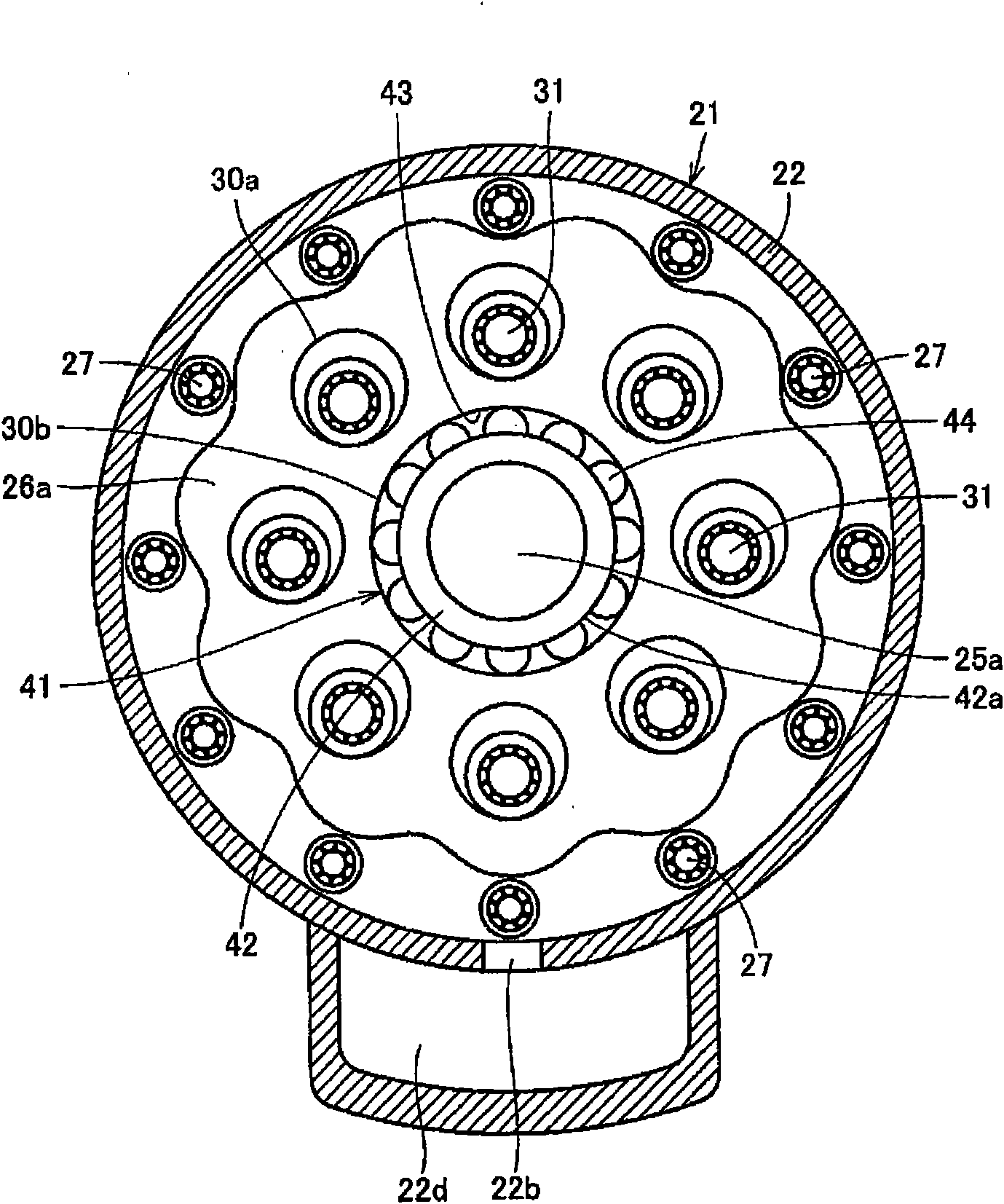

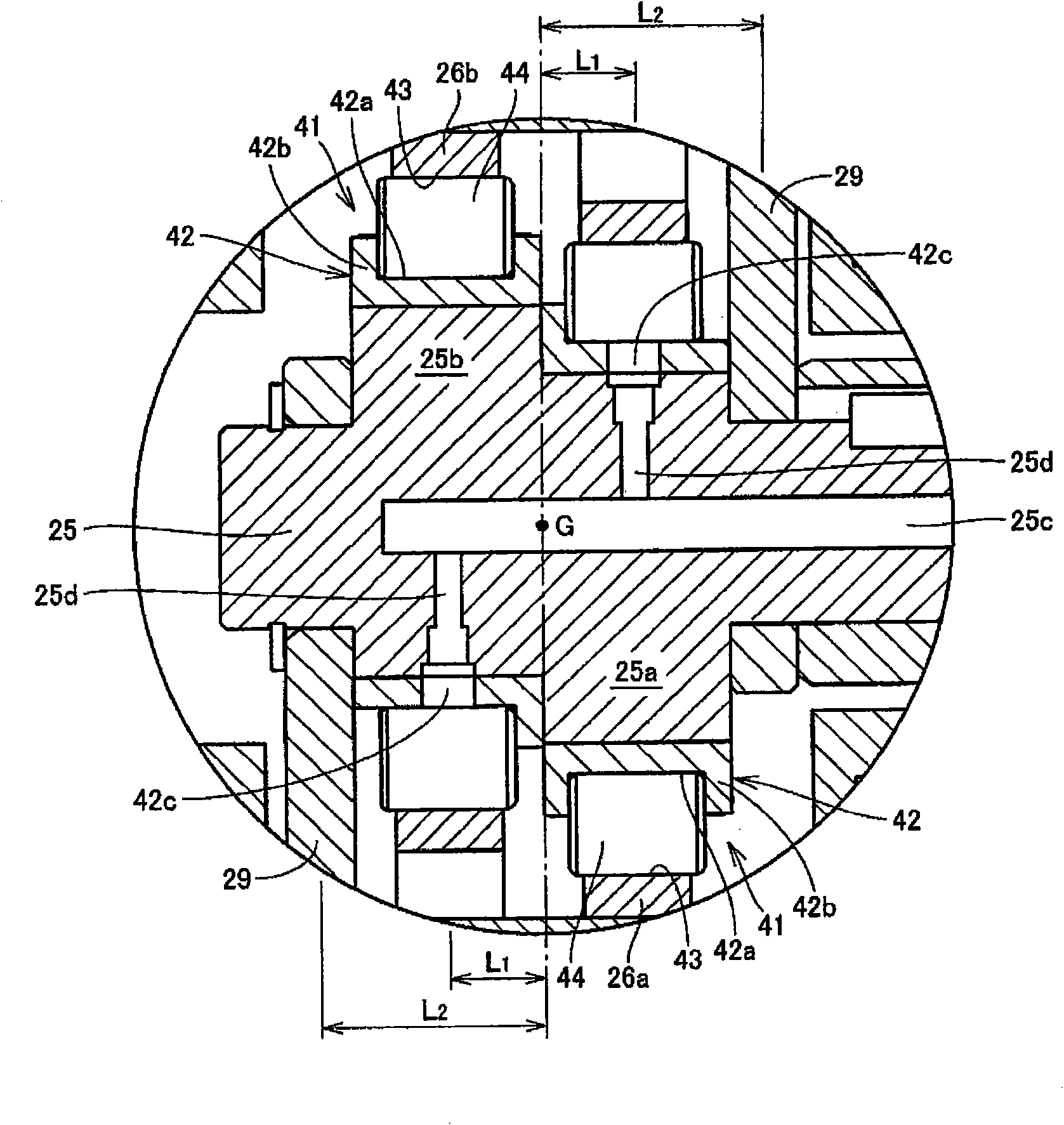

[0027] refer to Figure 1 to Figure 9 , the in-wheel motor drive device 21 according to one embodiment of the present invention will be described.

[0028] Figure 8 is a schematic diagram of an electric vehicle 11 employing an in-wheel motor drive device 21 according to an embodiment of the present invention, Figure 9 It is a schematic view of the electric vehicle 11 viewed from the rear. refer to Figure 8 The electric vehicle 11 includes a chassis 12 , front wheels 13 as steering wheels, rear wheels 14 as drive wheels, and an in-wheel motor driving device 21 that transmits driving force to the left and right rear wheels 14 . refer to Figure 9 , the rear wheel 14 is accommodated inside the wheel shell 12a of the chassis 12, and is fixed to the lower portion of the chassis 12 via a suspension device (suspension) 12b.

[0029] The suspension device 12b supports the rear wheel 14 by a cantilever extending left and right, and absorbs vibration received by the rear wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com