Electrical energy storage cell, electrical energy storage module and method for producing an electrical energy storage cell

A technology for electric energy storage and battery storage, which is applied in secondary battery manufacturing, alkaline battery manufacturing, primary battery to battery grouping, etc. It can solve the problems of increased wear and tear of switchgear, low efficiency of BDI, and increased manufacturing technology to achieve contact resistance. The effect of reducing, optimizing filling, and reducing construction space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

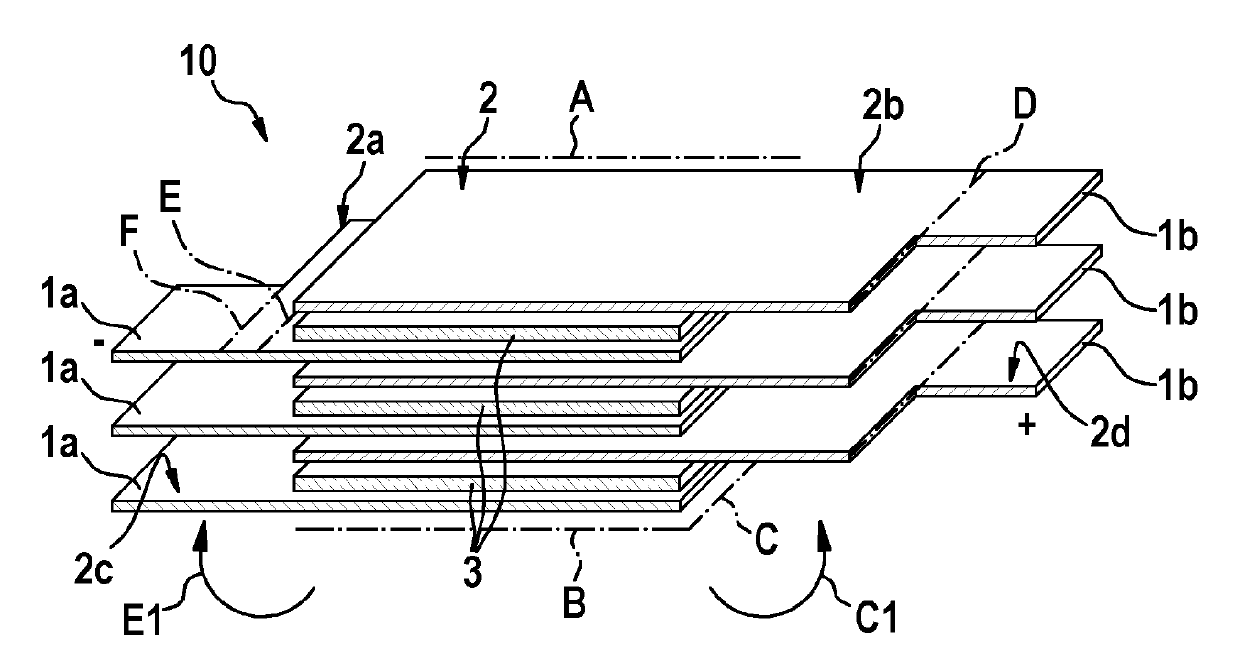

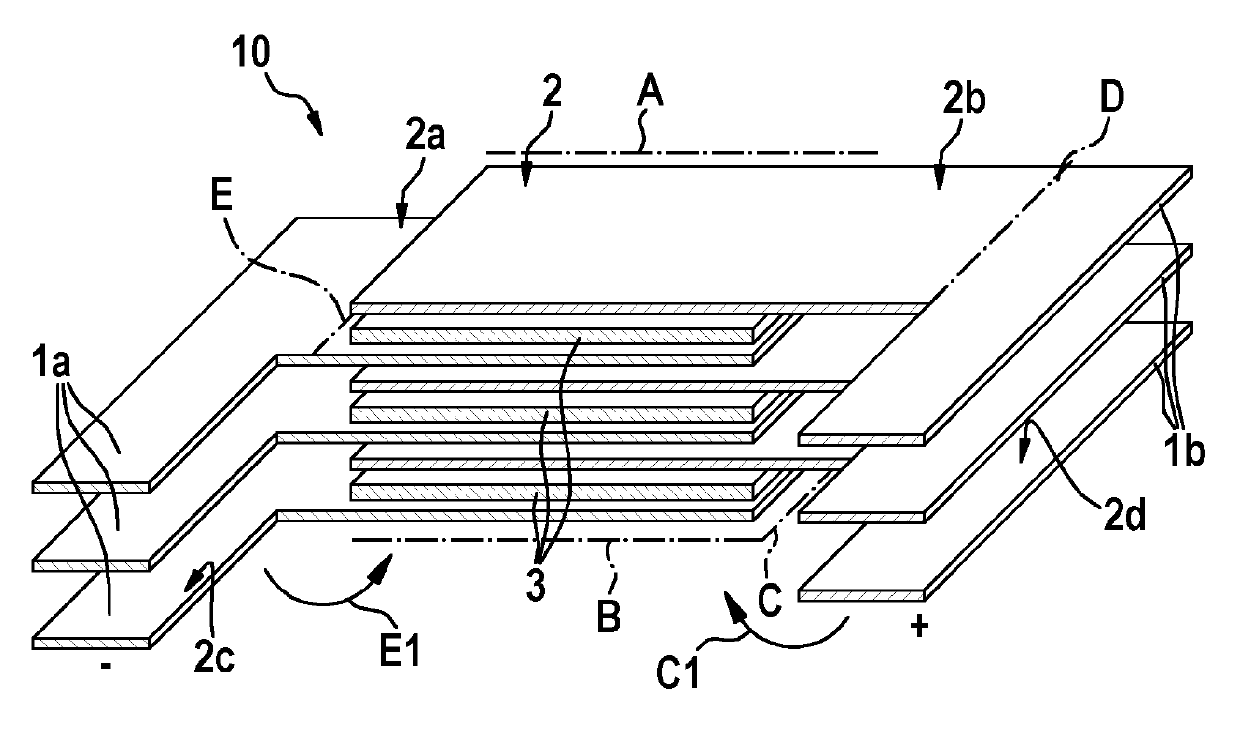

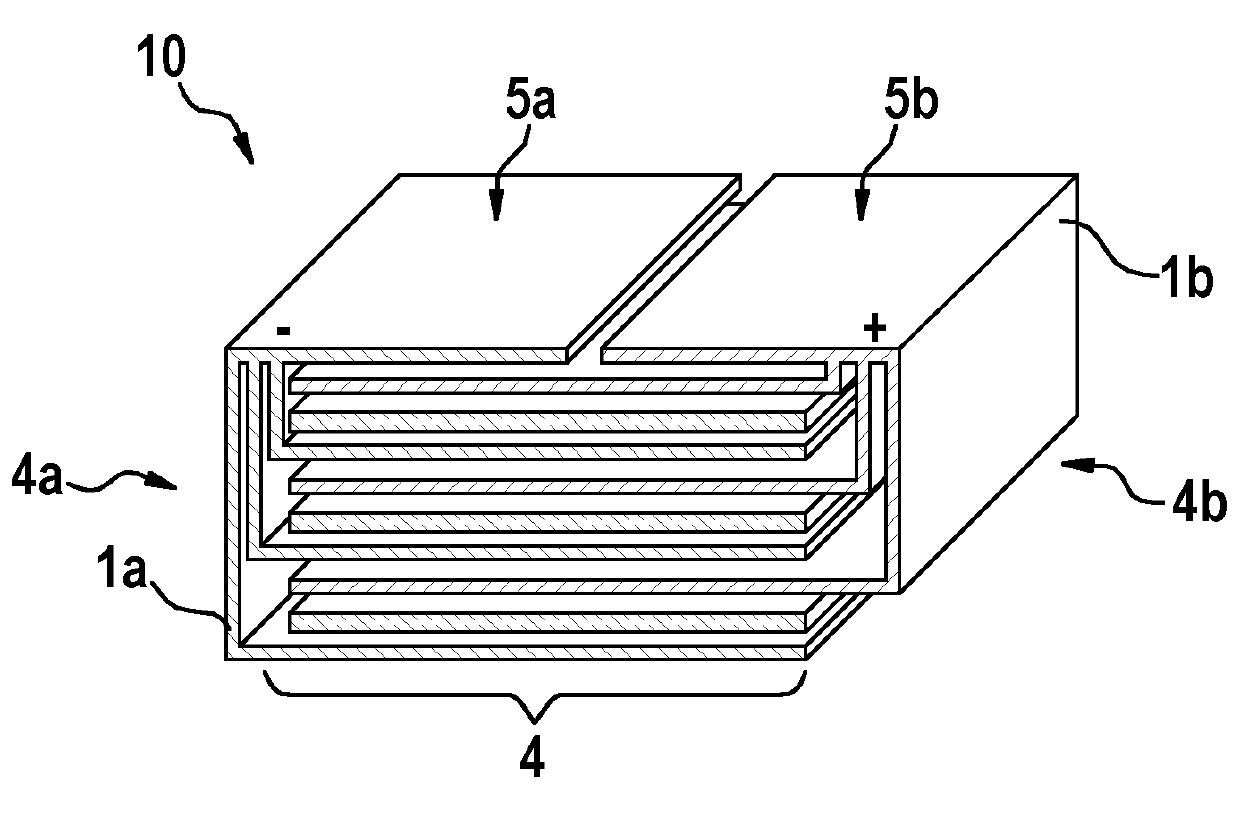

[0040] Electrical energy storage batteries within the meaning of the present invention include all devices which are capable of storing electrical energy for a predetermined period of time and delivering it again for another period of time. Energy storage cells within the meaning of the invention include all types of secondary and primary energy stores, in particular capacitive, electrochemical (Faraday) and combined storage types. The period of time considered can here range from a few seconds up to hours, days or years. Electrical energy storage batteries may include, for example, batteries based on lead, zinc, sodium, lithium, magnesium, sulfur or other metals, elements or alloys, lithium ion batteries, lithium polymer batteries, nickel metal hydride batteries, supercapacitors, supercapacitors, electric Capacitor, BatCap or similar system. The function of the electrical energy storage cells encompassed by the invention can be based here on intercalation electrodes, reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com