Dolly for overhead and gantry cranes

A crane and trolley technology, which is applied in the direction of load-carrying pulley, traveling mechanism, clockwork mechanism, etc., can solve the problems of increasing the bearing capacity of the main beam of the crane, the weight of the trolley, and the high energy consumption, so as to reduce the weight and cost, and reduce the height of the building. , the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

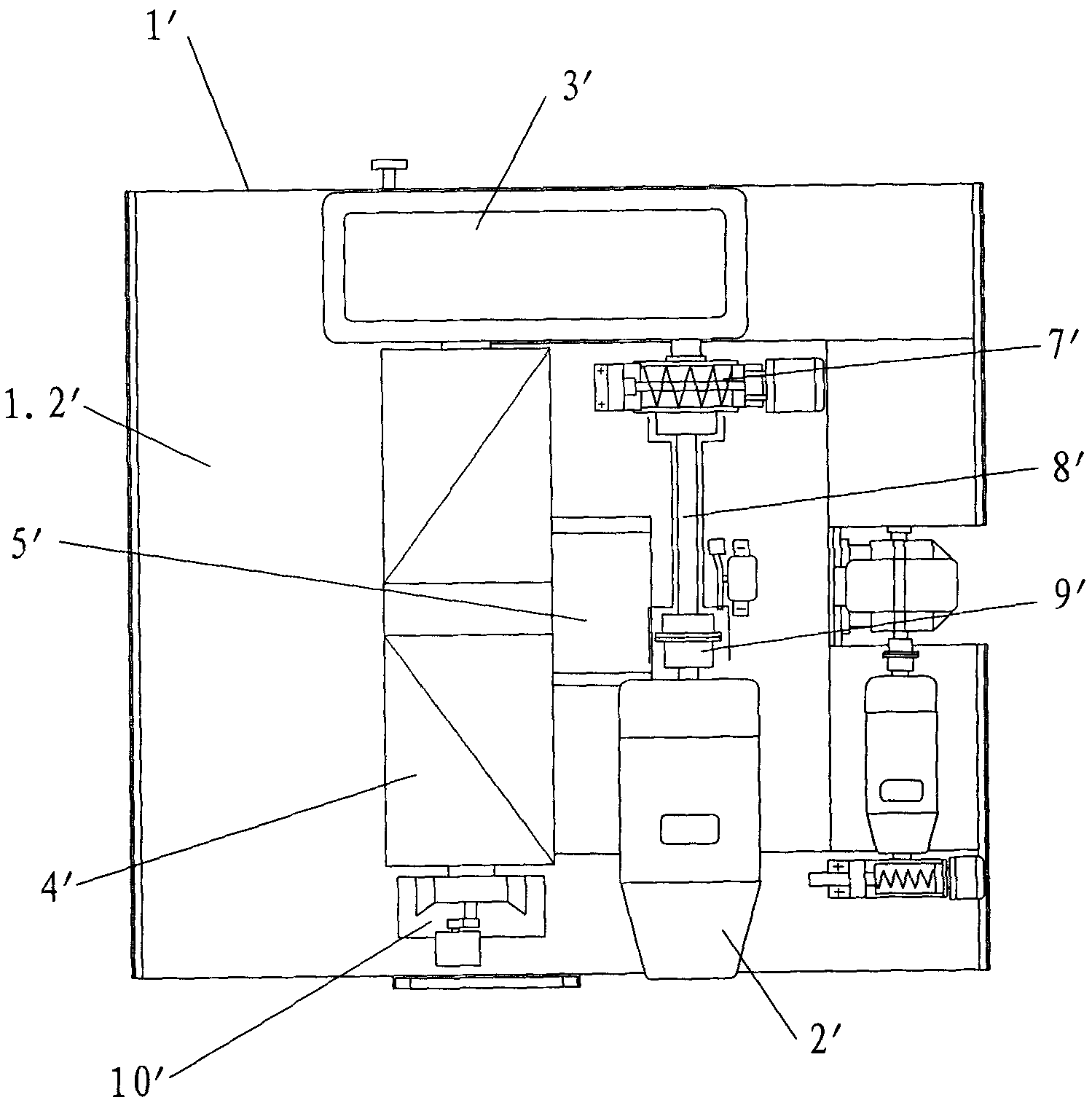

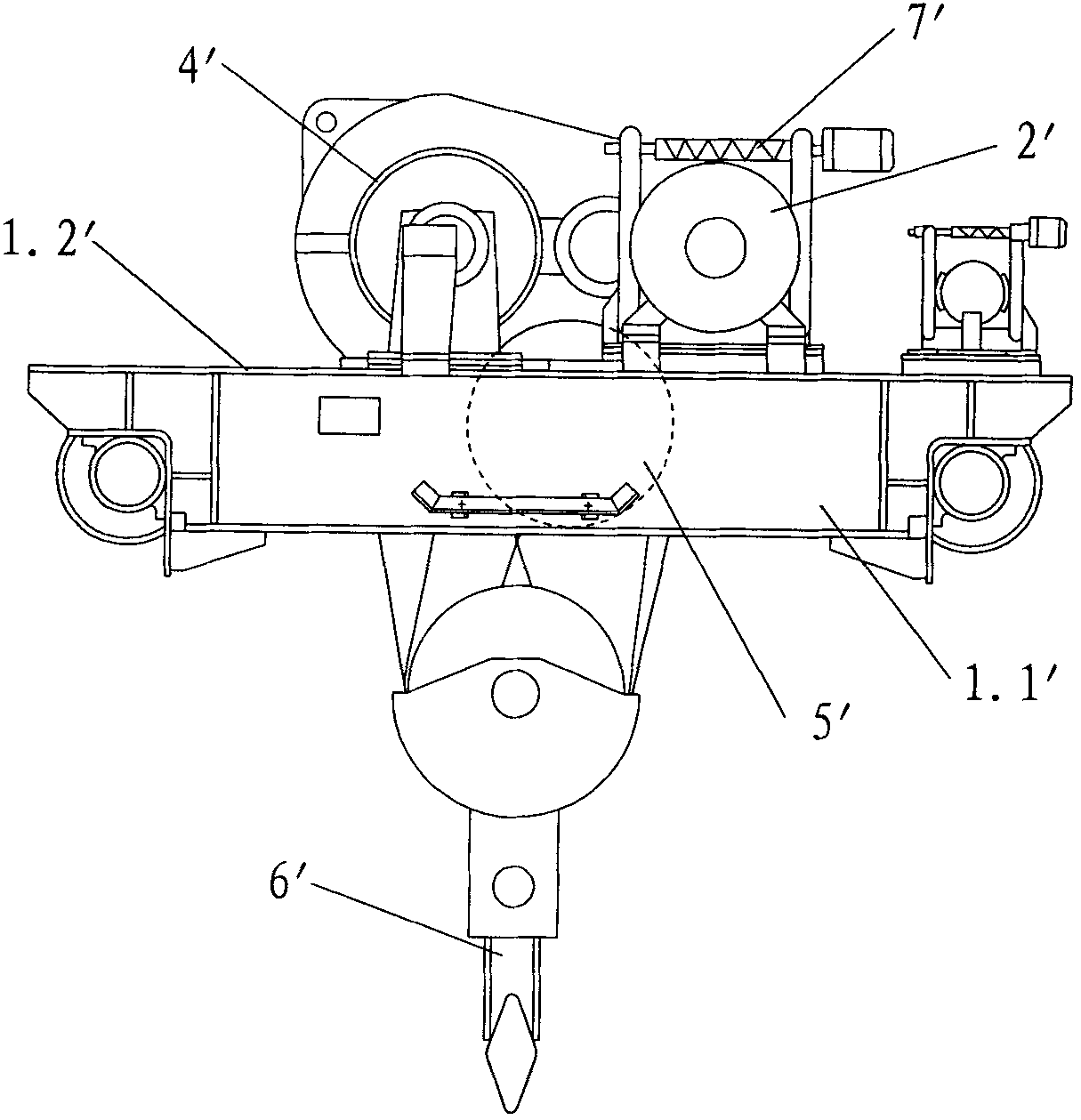

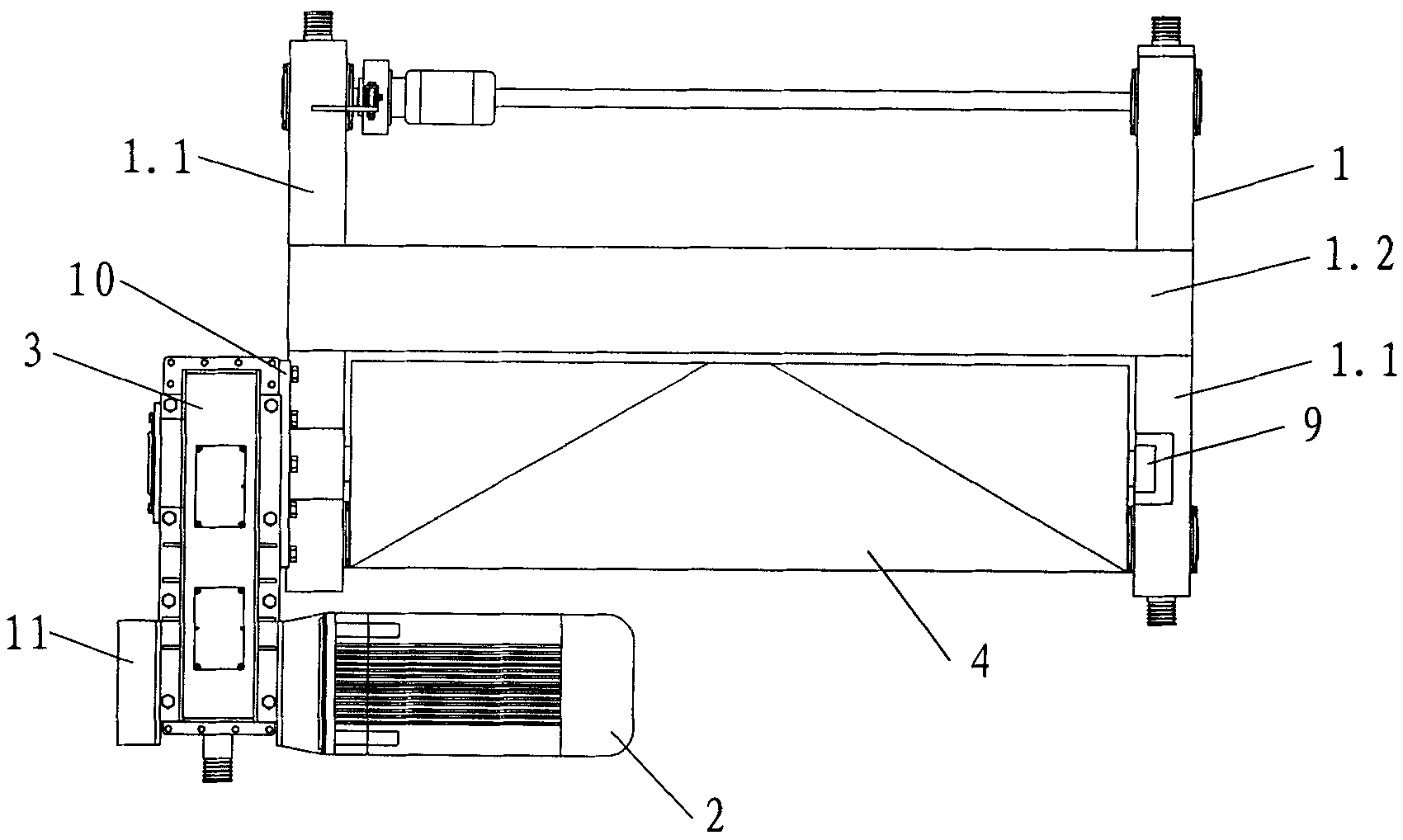

[0025] see image 3 , Figure 4 and Figure 5 As shown, the trolley for the gantry crane of the present invention has a lifting mechanism comprising a vehicle frame 1, a motor 2, a reducer 3, a reel 4, a fixed pulley block 5, a hook 6, a driving wheel set 7 and a driven wheel set 8. The vehicle frame 1 includes an end beam 1.1 and a main beam 1.2, the two end beams 1.1 are two, the main beam 1.2 is one, and the two end beams 1.1 are fixed on the main beam respectively. The two ends of the beam 1.2 form a frame structure, and the ends of the main beam 1.2 are respectively located at the middle positions of the two end beams 1.1. The reel 4 is located in the frame structure and parallel to the main beam 1.2. The reel 4 is rotatably mounted on the two end beams 1.1. In this specific embodiment, the two ends of the reel 4 are axially limited b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com