Variable Lens System

a lens system and variable technology, applied in the field of optical lens systems, can solve the problems of limited magnification of known electrowetting lenses, limited field flattening and aberration reduction possibilities, and the module is only suitable for low-resolution cameras, so as to reduce building height, reduce building height, and long focal range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

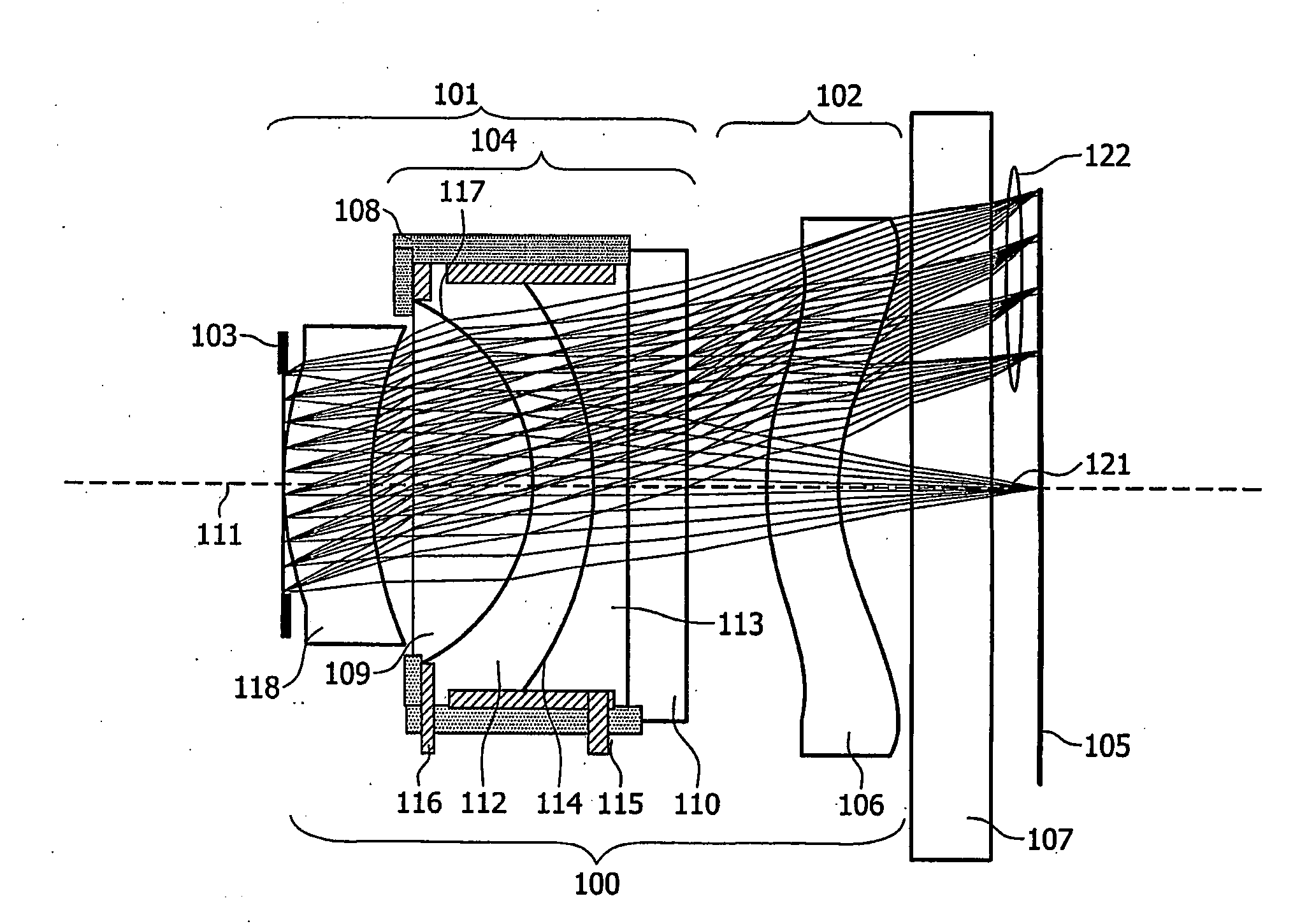

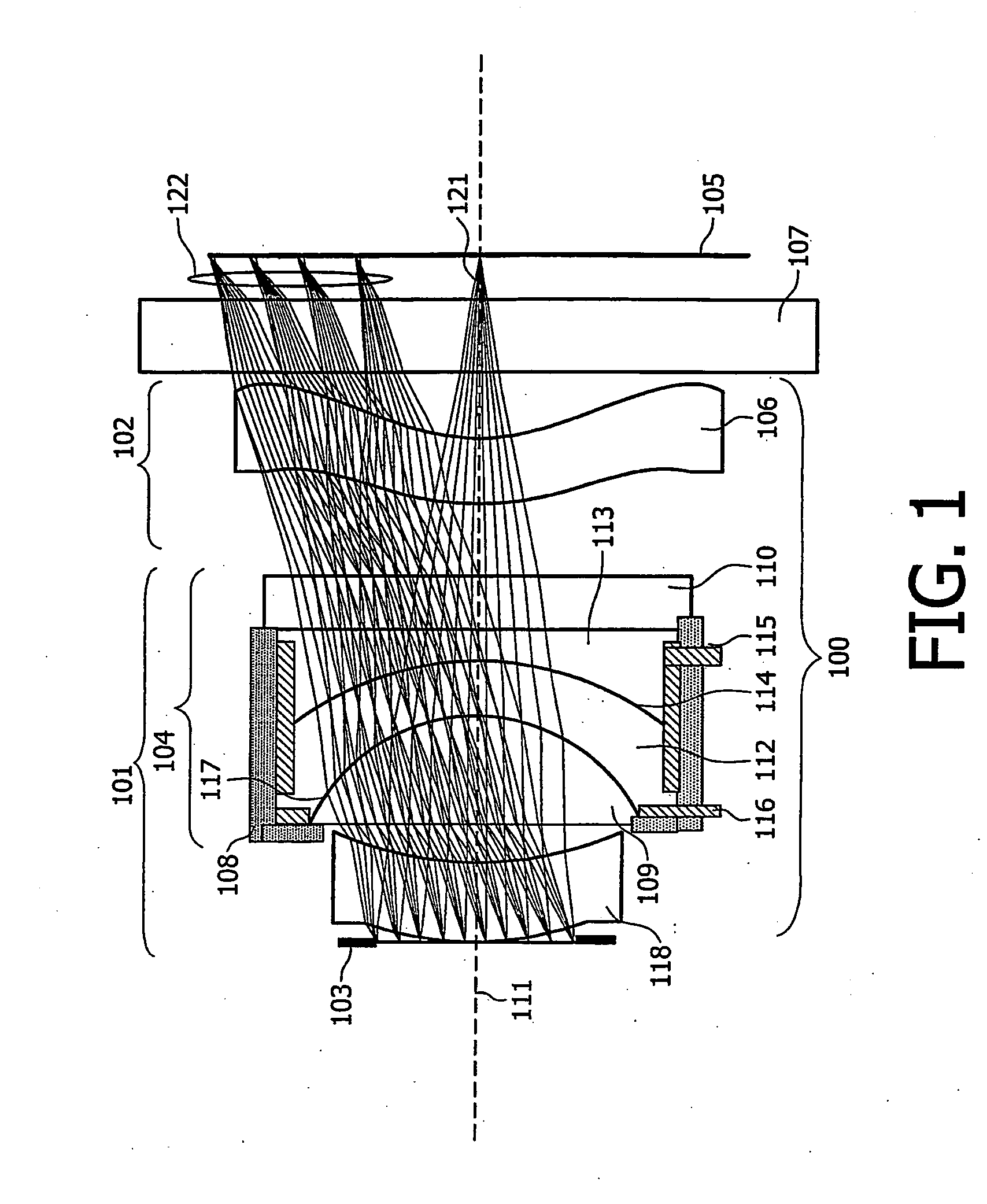

[0037]FIG. 1 schematically shows an optical lens system in accordance with the present invention. The optical lens system (100) comprises two lens groups 101 and 102 and a stop 103 located in front of the first lens group. The first lens group 101 comprises an electrowetting lens 104 as variable lens and acts as a variable focus lens. In the example shown in FIG. 1 the first lens group also determines the magnification of the optical lens system to match the size of the images to the size of the image sensor 105 located behind the optical lens system. The second lens group 102 comprises a field-flattening lens 106 that flattens the focal plane for light rays 122 entering from a field angle in the object space. The image sensor 105 is covered with a transparent cover 107, here a plan parallel plate.

[0038]The electrowetting lens includes a chamber 108 having an entrance window 109 and an exit window 110, and an optical axis 111 extending longitudinally through the chamber. The chamber...

second embodiment

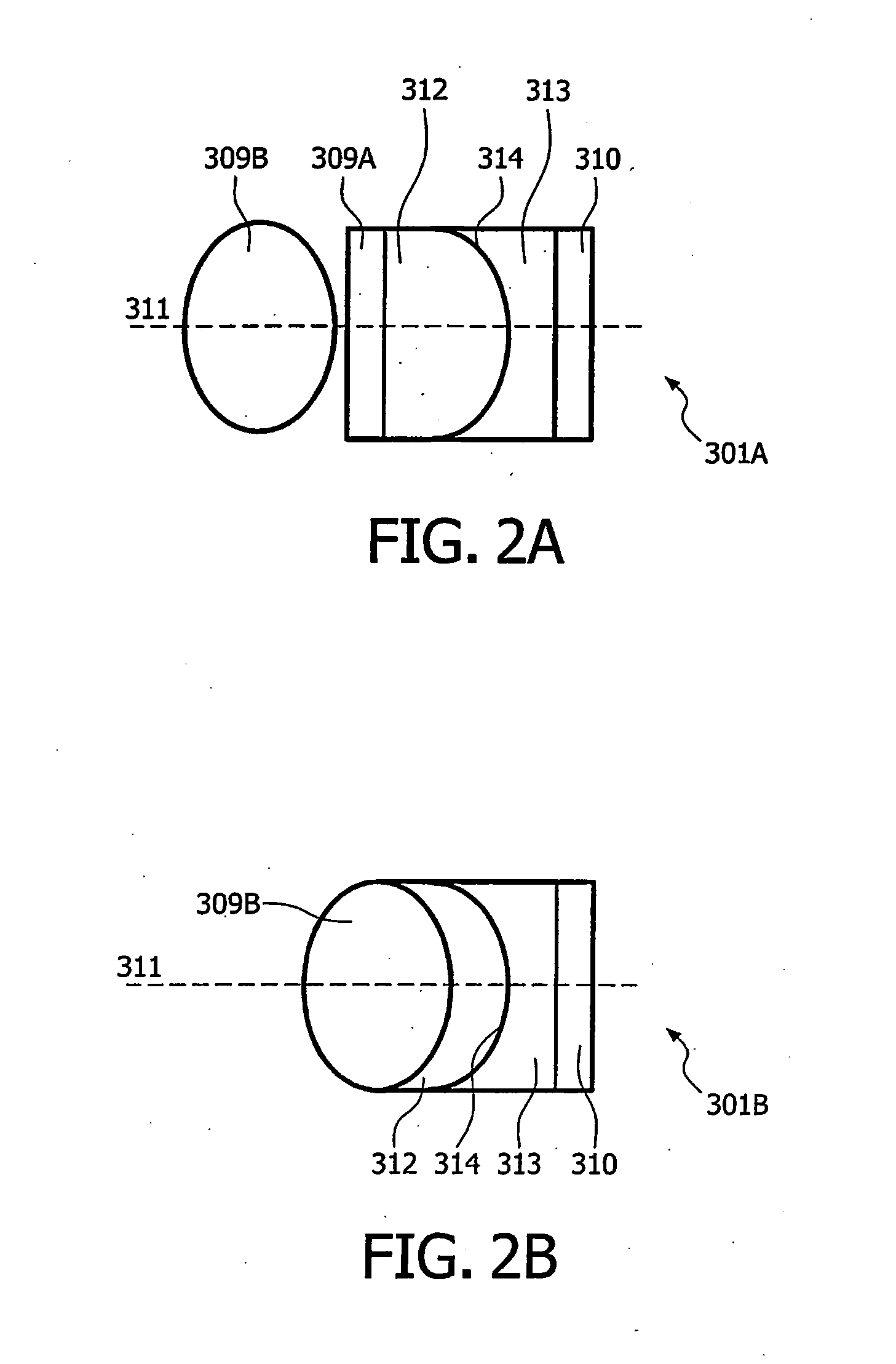

[0048]In the invention, the electrowetting lens can be made substantially achromatic by a proper choice of the materials of the contacting fluid 112 and the entrance window 109 in combination with an optimised surface curvature for the fluid-window interface 109. This choice of materials may be done on parameters such as refractive index and Abbe-number.

[0049]In order to be able to have sufficient freedom in choosing the appropriate lens materials and fluids it is required to allow of a wide range of refractive indices. This can result for example in a substantial difference in refractive index of the material used for the window and the contacting fluid. Allowing such a substantial difference in refractive indices also requires a substantial difference in Abbe-numbers for the window and fluid to optimise for a substantially achromatised electrowetting lens. The choice of materials for window, fluid and curvature also may be optimised for substantially achromatising the total optica...

third embodiment

[0053]FIG. 4 shows schematically an optical lens system according to the invention is schematically shown. In this embodiment a combination of choices of fluids and window materials (choices for e.g. refractive index and Abbe-number) with choices of the curvature of both the surfaces of the entrance and exit window is used to substantially reduce the aberrations introduced by the electrowetting lens or even total optical lens system. The optical lens system 200 comprises two lens groups 201 and 202 and a stop 203 located between the first and second lens group. The first lens group 201 comprises an electrowetting lens 204 as variable lens and acts as a variable focus lens. The second lens group 202 determines the optical magnification using a lens 220 to match size of the images with the size of the image sensor 205 located behind the optical lens system. Also it reduces the chief-ray angle by means of a field-flattening lens 206. The image sensor 205 is covered with a transparent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com