Lifting device used on rubbish compression machine (station)

A garbage compressor and garbage technology, which is applied in the direction of garbage transmission, garbage collection, storage devices, etc., can solve the problems of increasing space height, inconvenient maintenance of oil cylinders, complex structure, etc., and achieve stable operation, convenient maintenance and installation, and remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

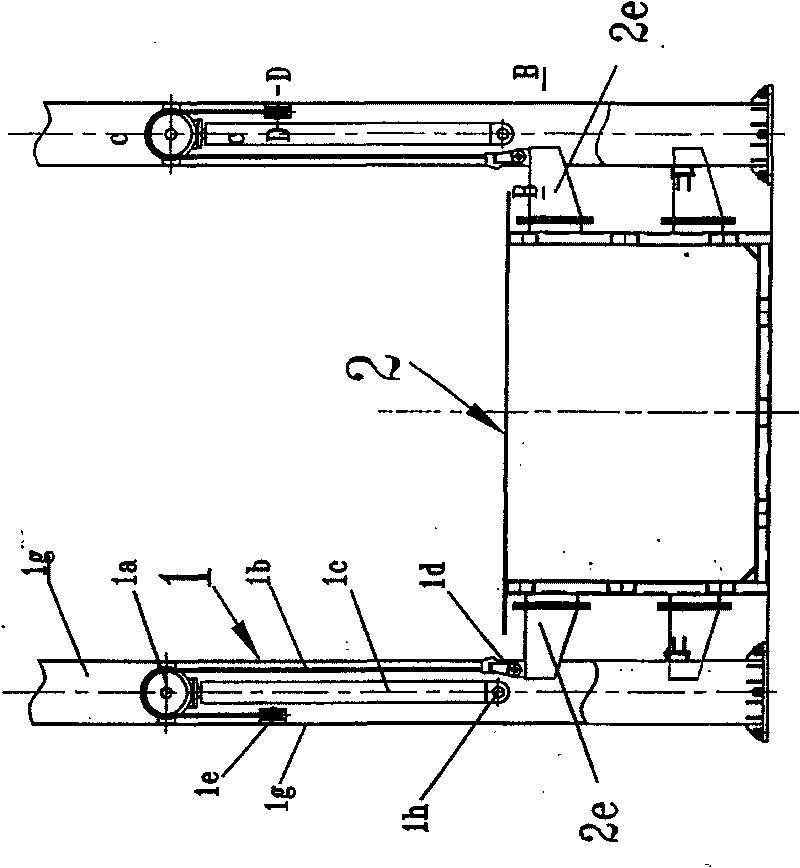

[0017] Embodiment 1: see Figure 1-Figure 4

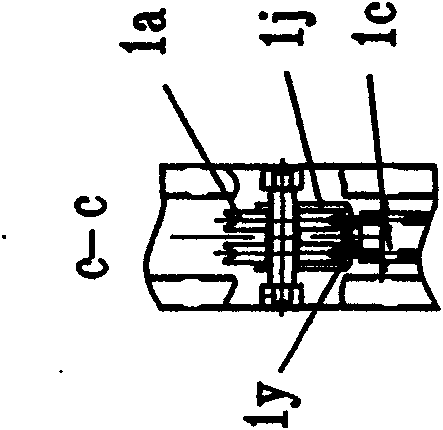

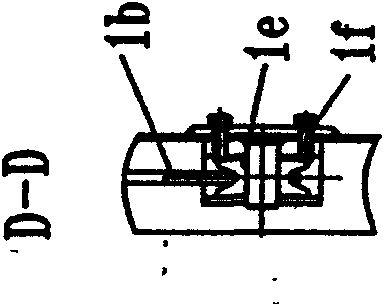

[0018] A lifting device used on a garbage compressor, including a garbage compressor and a lifting device, is characterized in that: a cantilever beam 2e is fixed on the garbage volume box 2 of the garbage compressor; the lifting device 1 is composed of a column 1g , an oil cylinder lifting mechanism, and a pulley and sliding rope transmission mechanism; the four columns are arranged on both sides of the garbage bin, and their cross-sections are concave-shaped and hollow with openings, which are formed by pressing steel plates, and the cavities are respectively disposed from the opening Enter the oil cylinder lifting mechanism and the pulley sliding rope transmission mechanism; the described oil cylinder lifting mechanism is composed of the lifting cylinder 1c, the piston 1y, the transmission pulley seat 1j fixed on the top of the piston, and the oil cylinder seat 1h fixed on the lower end of the oil cylinder, wherein the oil cylin...

Embodiment 2

[0020] Example 2: see Figure 5

[0021] A lifting device used on a garbage compression station, including a garbage compression station and a lifting device. The difference between this lifting device and Embodiment 1 is that the lifting lug 2g is fixed on the cantilever beam 2e of the garbage volume box 2, The end of the sliding rope 1b is hinged on the suspension hook 2L with a rope clamp 1d, and the suspension hook is connected with the lifting lug.

[0022] The working principle of this lifting device is: the oil cylinder lifting mechanism drives the pulley and the sliding rope transmission mechanism drives the garbage volume box to lift; during work, the load-bearing pulley only bears the load and its position is fixed. When the lifting cylinder is lifted by one meter, the transmission pulley on the top of the piston Thereupon one meter rises, because the sliding rope on the driving pulley is fixed around or hinged at one end in the load-bearing pulley, so the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com