Method for casting concrete 0# block support by continuous beam cantilever

A technology of pouring concrete and supporting methods, which is applied to bridges, buildings, bridge construction, etc., can solve the problems of difficulty in ensuring the rigidity of supports, many support materials, and uneconomical steel pipe supports for high-pier bridges, and achieve simple structure, easy installation, and use less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

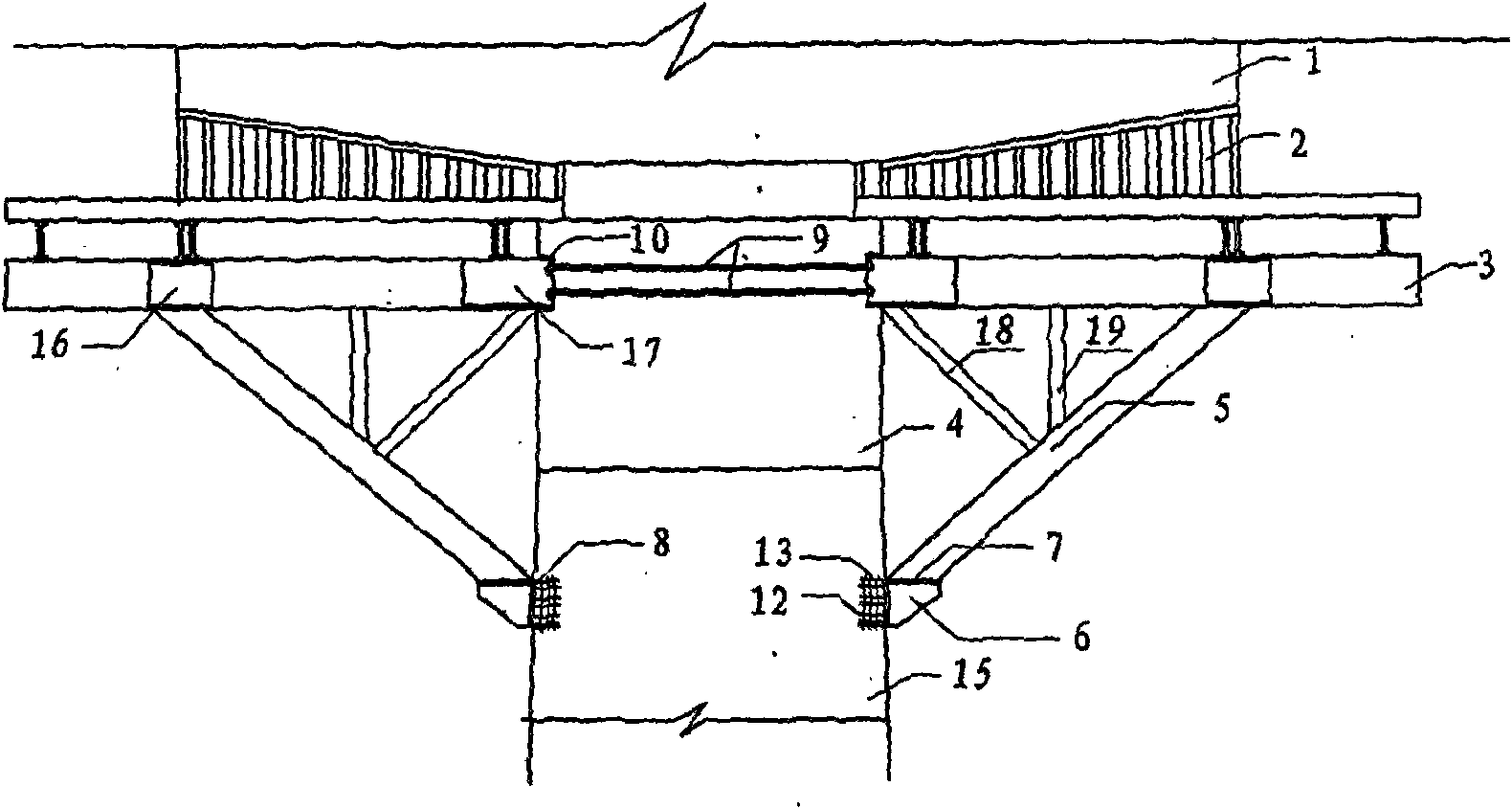

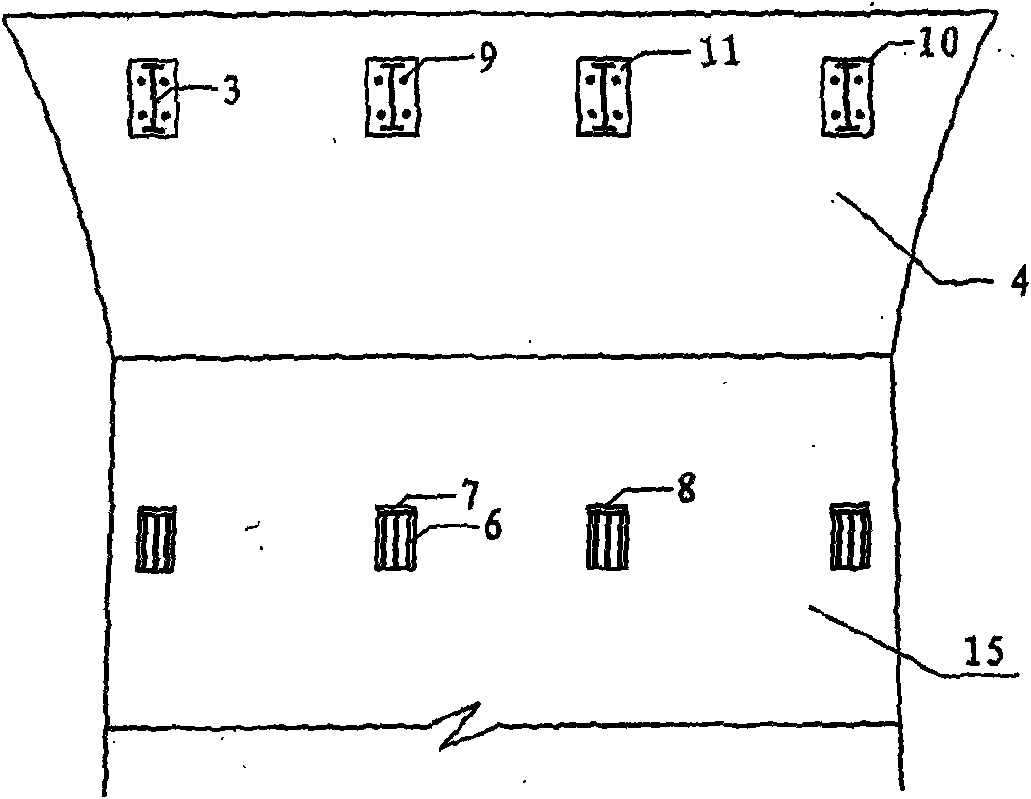

[0018] Example: The construction of the Beishahe Super Bridge on the Yiha-Dalian Passenger Dedicated Line as an example:

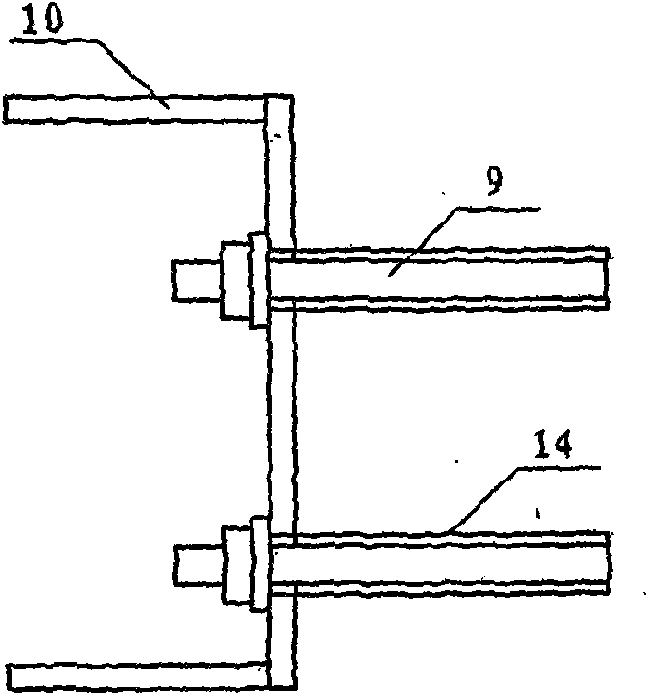

[0019] Each triangular bracket consists of 1 triangular bracket I-steel horizontal bar made of I 56 I-steel, 1 triangular bracket I-steel diagonal brace made of I 40 I-steel, and 1 triangular bracket I-steel diagonal brace made of I 40 I-steel, and 1 with] The triangular bracket channel steel vertical brace made of 40 channel steel and one triangular bracket channel steel diagonal brace made of ]40 channel steel are composed of the triangular bracket I-steel horizontal bar length of 5.5m, and the triangular bracket The length of the I-beam diagonal brace is 5.0m, and the triangle bracket I-beam diagonal brace is welded to the triangle bracket I-beam horizontal rod at a distance of 4.2m from one end of the triangle bracket I-beam horizontal rod to form an included angle of about 43° , the welding seam is required to be free of defects, fully welded, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com