Continuous process of roll-forming stamped sheet

a continuous process and stamping technology, applied in the direction of girders, bumpers, manufacturing tools, etc., can solve the problems of inability to change the material properties within the part, the inability to change the cross section along the length of the part, and the limitations of roll-forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

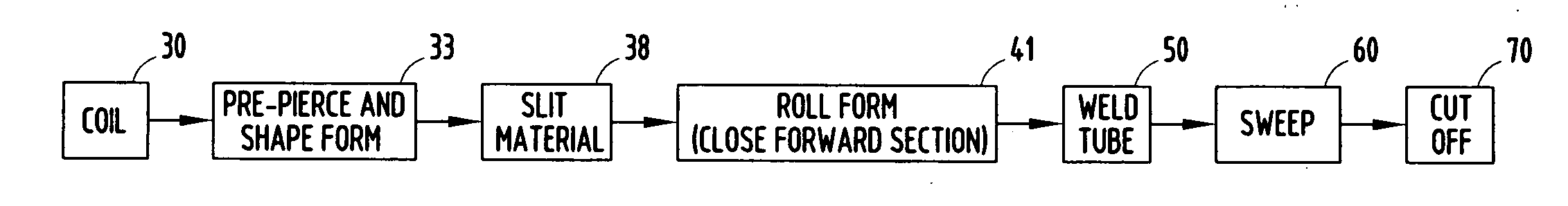

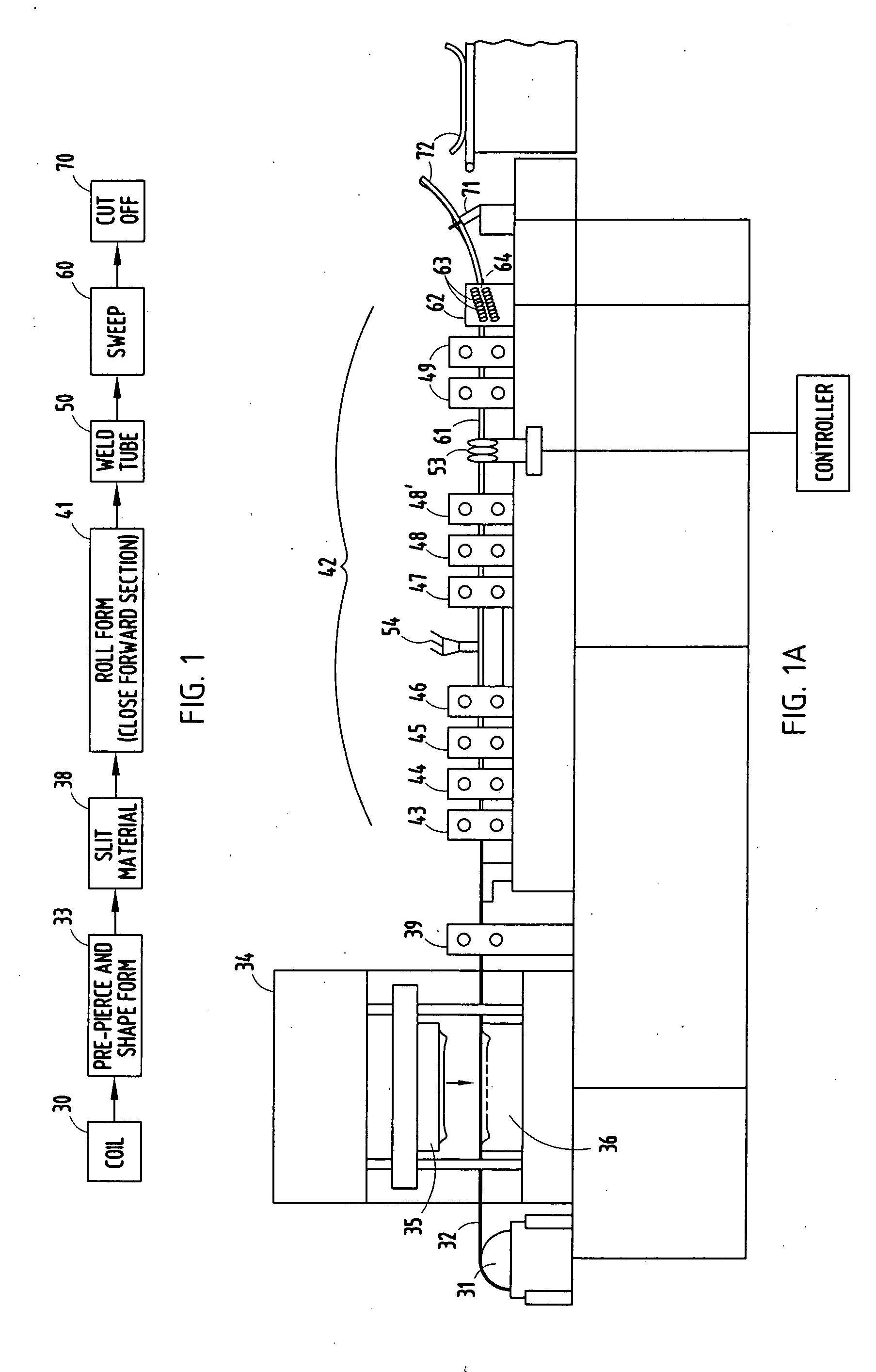

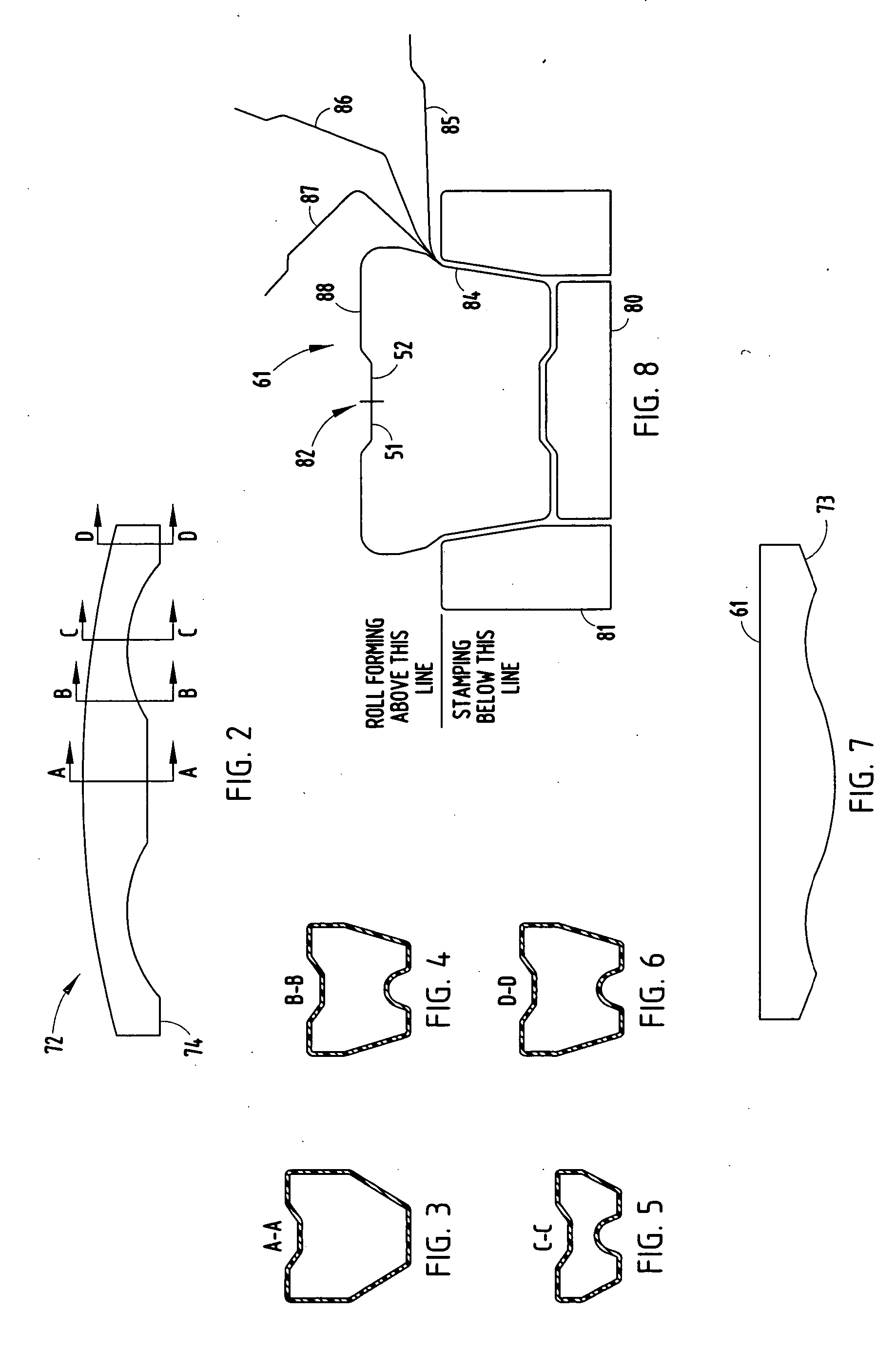

[0022] The current invention defines a way to produce roll-formed tubular beams with varying cross sections from high-strength sheet material, such as materials of over 80 ksi tensile strength and even ultra-high-strength steel of over 140 ksi tensile strength (sometimes called “UHSS” or “AUHSS” material). For example, a DP980 (DF140) material has successfully been used. The ability to change cross sections along the length of the beam is achieved by combining a pre-forming process via stamping with the roll-forming. The stamping process and roll-forming operations are done in-line and sequentially. Sequential processes in-line without the need for secondary handling results in a very cost efficient manufacturing process. The stamping press is used to pre-form material as well as pre-pierce the sheet material and add features before it travels through the roll-forming tooling. The stamping of the material while it is in the flat produces a shape with varying depth and geometry acros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com