Large-span tunnel excavation method for upper soft and lower hard compound strata

A composite stratum and tunnel excavation technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as the inability to ensure the safety of tunnel upper steps, the inability to realize mechanized construction, and the small working space of the excavation surface. Good benefits, reduced construction procedures, shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

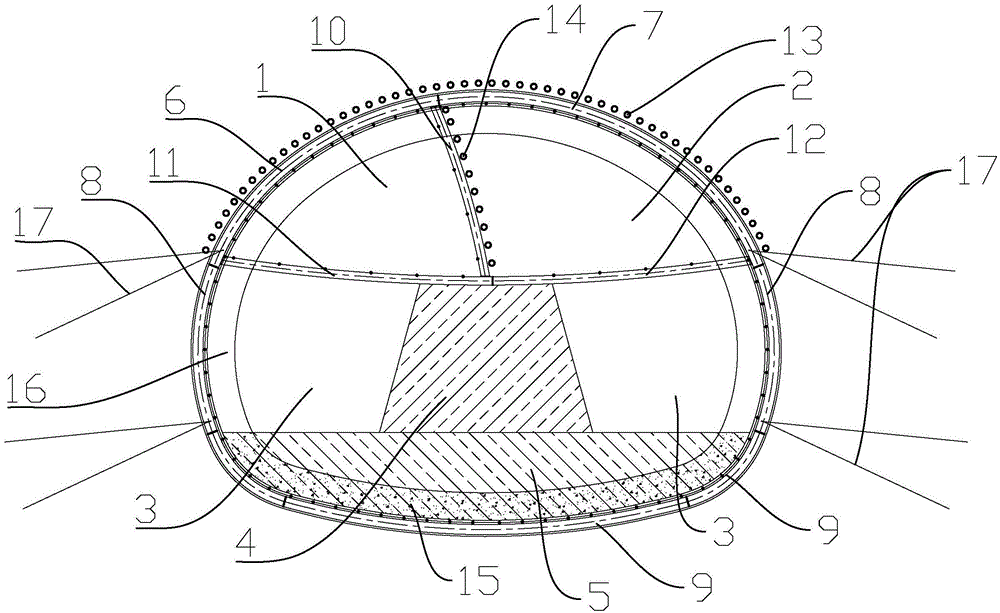

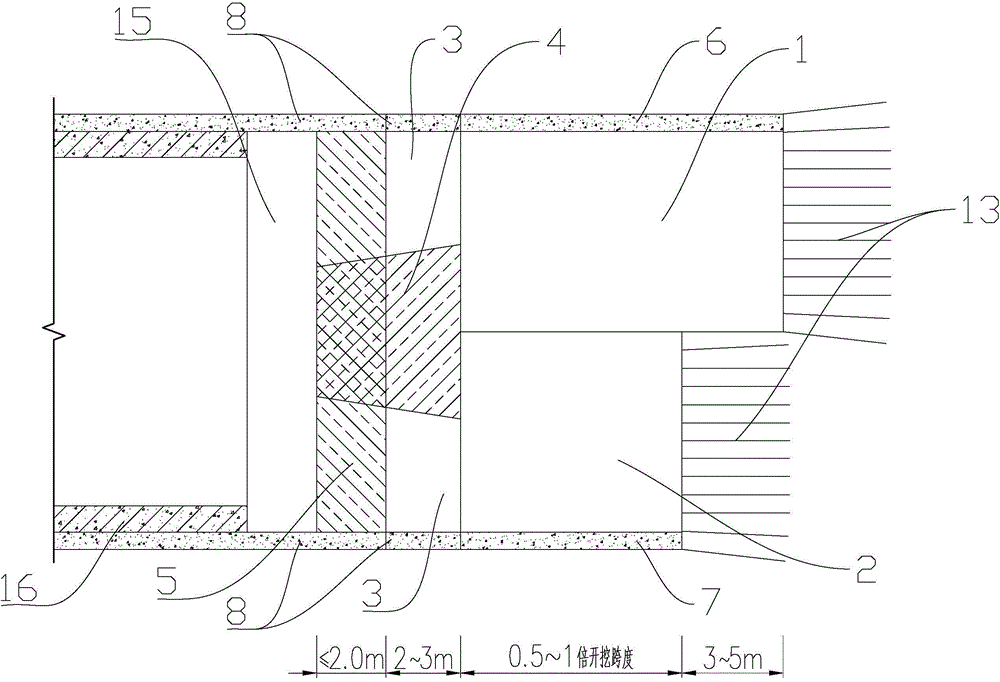

[0020] Such as figure 1 , figure 2 As shown, this embodiment is a method for excavating a long-span tunnel in an upper-soft and lower-hard composite stratum. In this method, the tunnel is divided into upper and lower steps for excavation. The specific steps are as follows:

[0021] a. According to the geological survey data, determine the dividing line between the soft and lower hard strata on the excavation surface, and select an economical and reasonable excavation height for the upper bench. The upper and lower bench dividing line should coincide with or be below the stratum dividing line.

[0022] b. The upper steps pass through the soft soil layer, and the middle partition method is used for construction; the upper steps are divided into the upper step first guide tunnel 1 and the upper step rear guide tunnel 2 for construction. protection (including the initial support 6 of the leading tunnel before going up the steps and the initial support 7 of the leading tunnel aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com