Non-net polyphenyl plate cast-in-place concrete exterior wall heat-preserving construction method

A construction method and external wall thermal insulation technology, applied in thermal insulation, walls, structural elements, etc., can solve problems such as shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

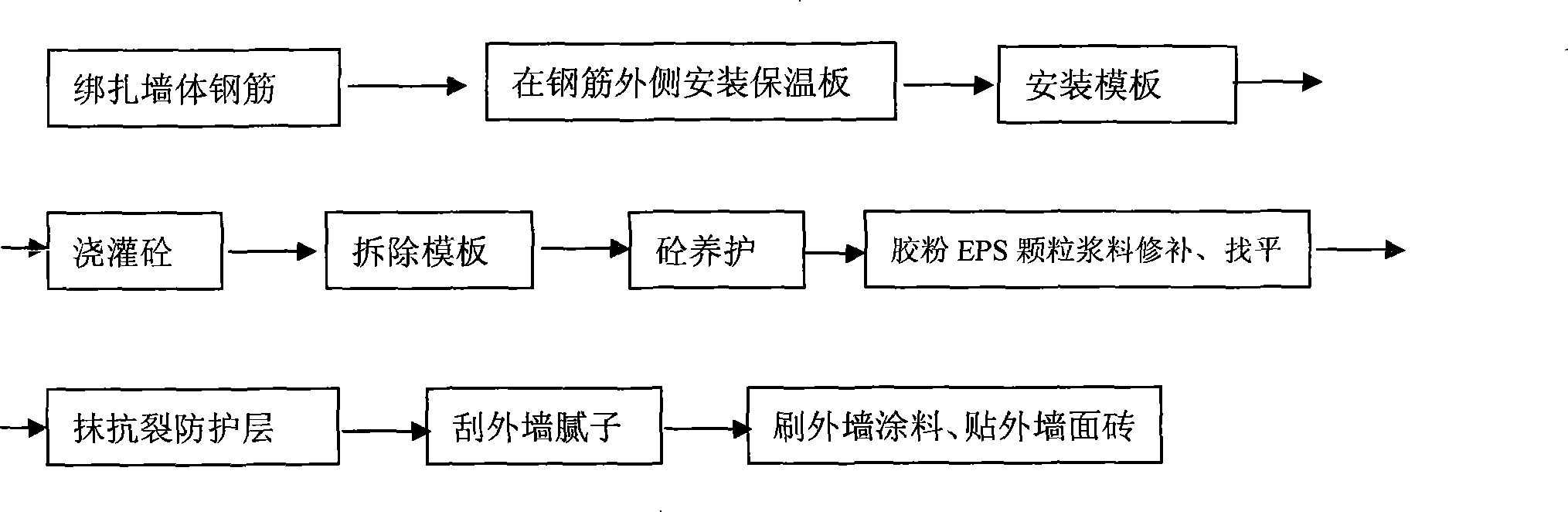

[0006] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0007] Given by process flow chart, the present invention is realized by the following steps:

[0008] 1. Binding the wall reinforcement:

[0009] The method is to bind steel bars on the outside of the wall, and the steel bars are bent to form shape, so as not to puncture the insulation board with straight ribs. After binding the steel bars of the wall, bind cement pads (plastic cards are not allowed) on the outside of the external wall steel bars. Each insulation board shall not be less than 6 pieces to ensure the thickness of the protective layer and ensure that the thickness of the protective layer is uniform. After the steel bar binding is completed, the concealed acceptance of the steel bar project shall be carried out in time.

[0010] 2. Install the insulation board on the outside of the steel bar, the method is:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com