Construction method of railway tunnel lining side wall concrete

A construction method and concrete technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of numerous pouring procedures, increased construction difficulty and cost, poor integrity of the tunnel lining concrete circle, etc., to enhance the structure and appearance quality, The effect of shortening the construction period and reducing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

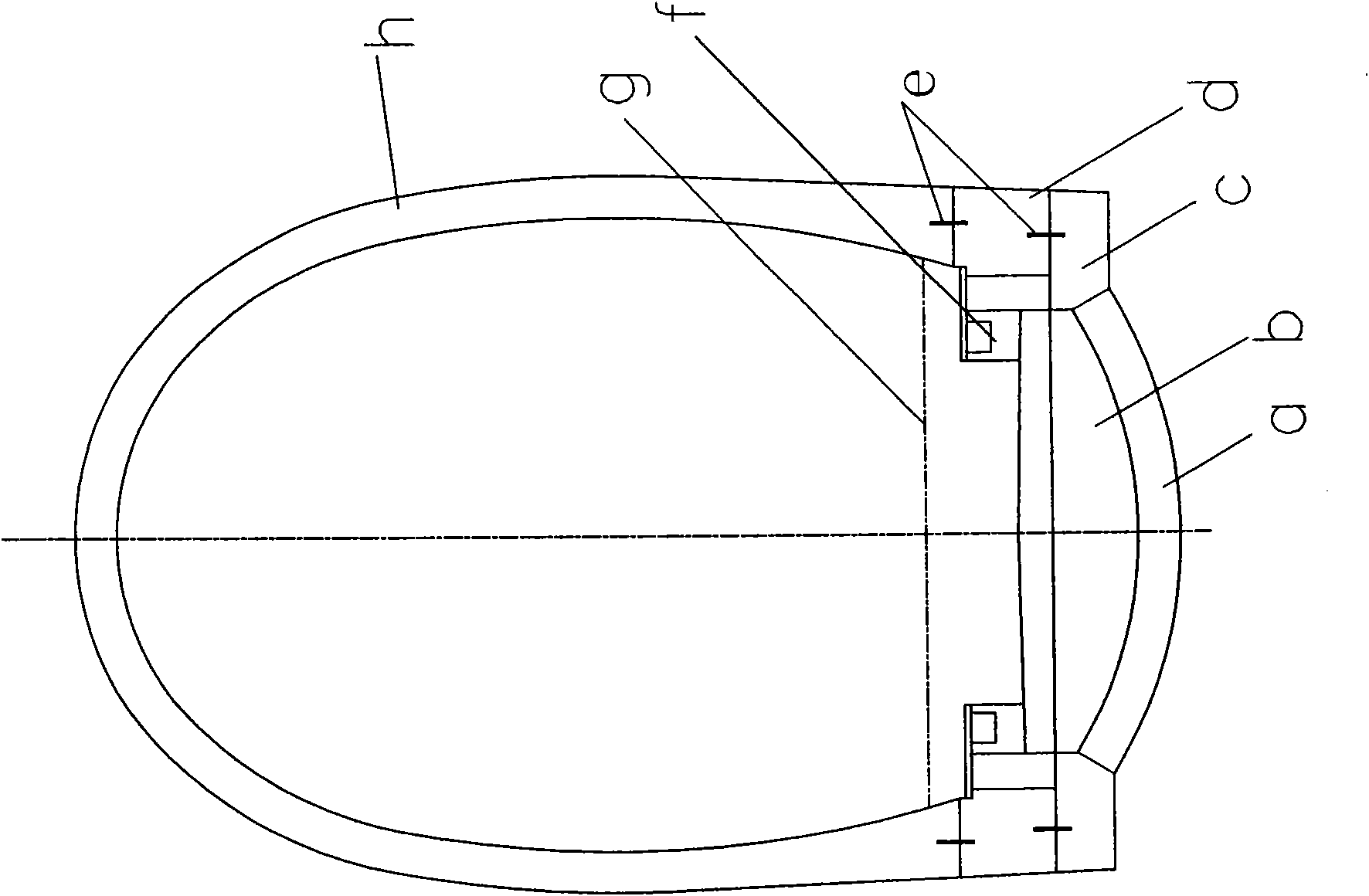

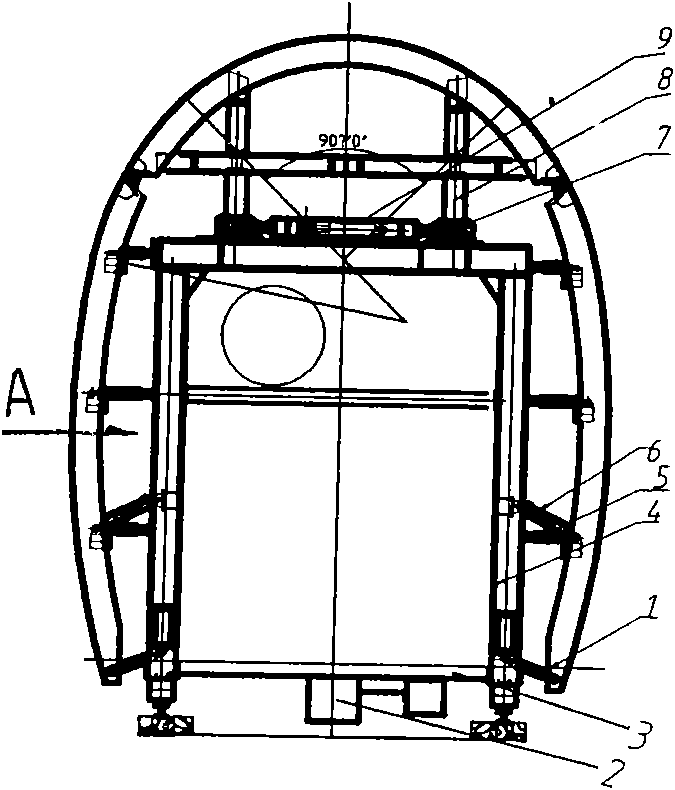

[0031] exist figure 1 In the known or prior art railway tunnel lining concrete construction steps, the existing railway tunnel lining trolley and formwork structure are used: inverted arch concrete a; the part below the ditch f is filled with concrete b; the part of the side wall foot concrete c below the ditch and buried Concrete d of the low side wall and embedded stubble reinforcement e; the first step is to pour the concrete below the bottom of the ditch, and the part above the bottom of the ditch f is filled with concrete to form the tunnel bottom g; the second step is pouring The concrete of the short side wall below the top of the ditch cover plate is completed; the third step is to pour the concrete arch wall h of the tunnel; three processes are required to complete the concrete pouring of the tunnel arch wall.

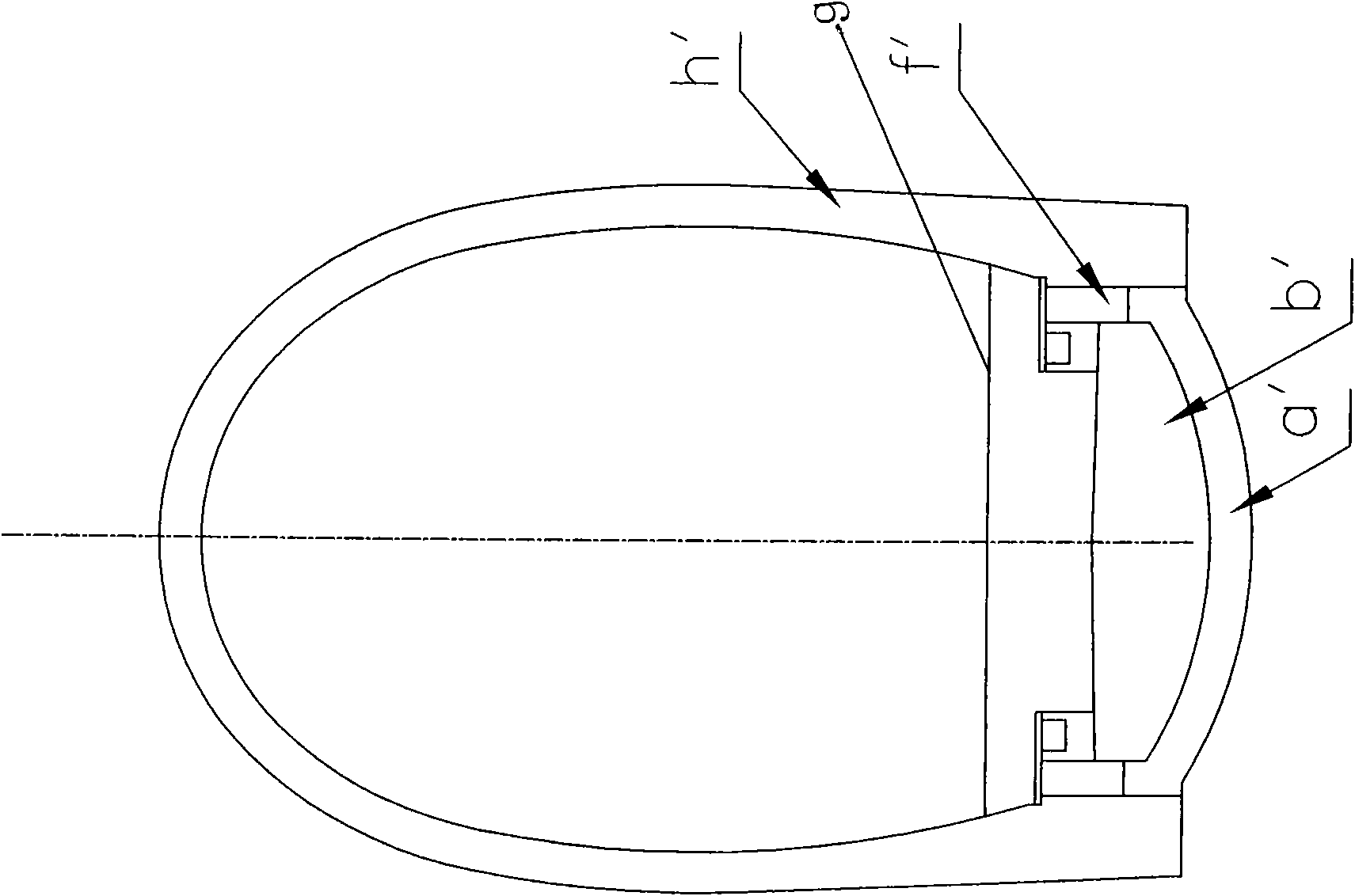

[0032] In the railway tunnel lining concrete construction steps of the present invention, the lining trolley and formwork structure of the present invention a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com