Construction method for two-side reinforcing engineering structure

A technology of engineering structure and construction method, which is applied in the direction of bridge reinforcement, building structure, building maintenance, etc., and can solve the unfavorable application of high-strength composite prestressed tensioning and anchoring, low work efficiency, easy to damage the main steel bar, etc. problems, to achieve remarkable application effect, convenient operation, and reduce the difficulty of design and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

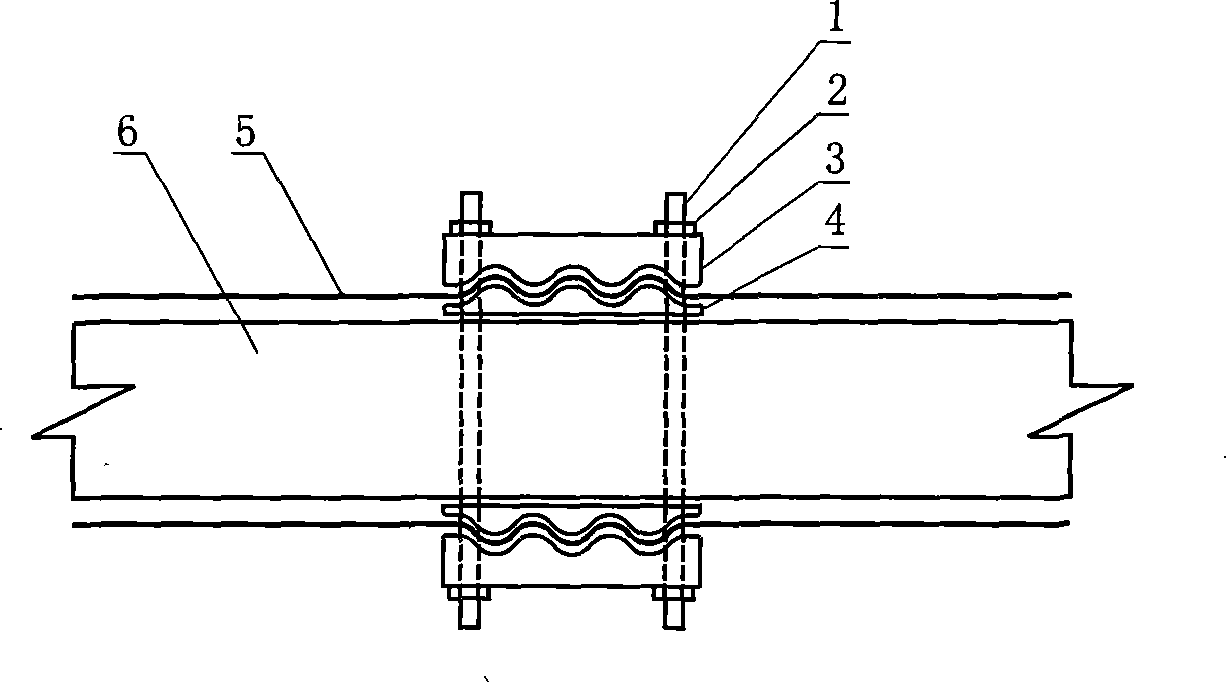

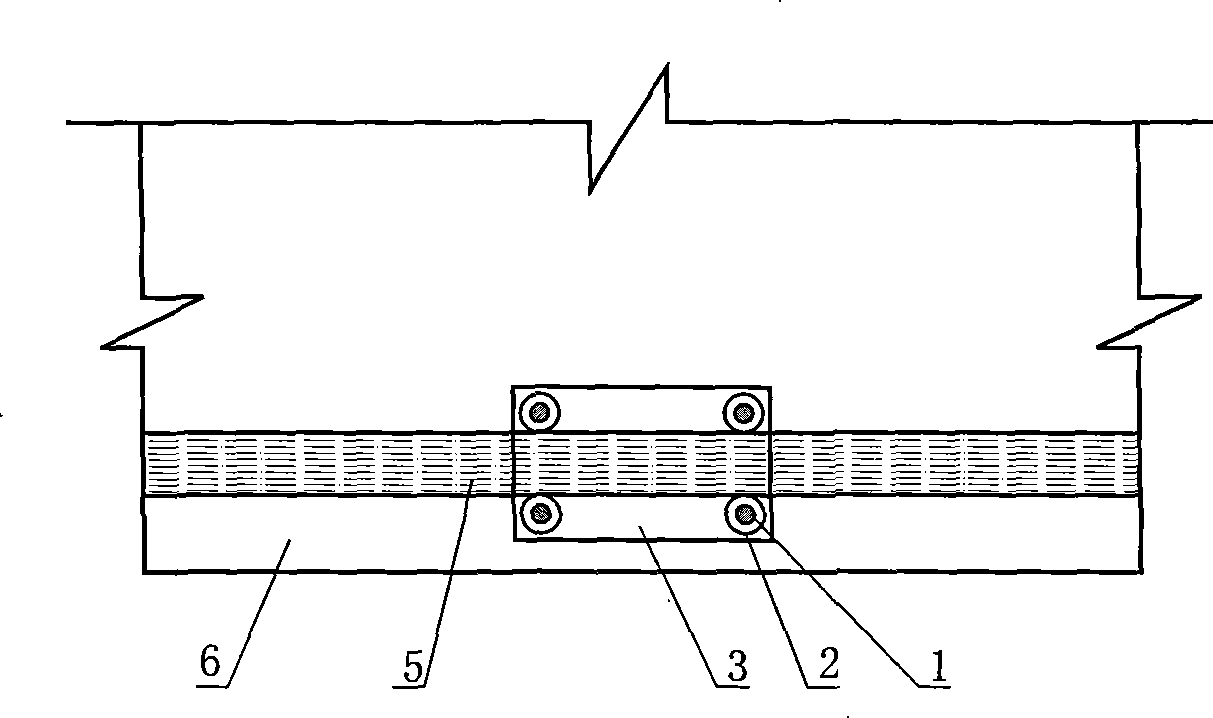

[0030] As shown in Figures 4 to 6, a construction method for reinforcing a reinforced concrete T-beam engineering structure with a length of 30 meters, a height of 1.75 meters, and a web thickness of 0.18 meters with carbon fiber composite material sheets on both sides.

[0031] The T-shaped beam 7 has a length of 30 meters, a beam height of 1.75 meters, and a web thickness of 0.18 meters. The T-shaped beam is a prestressed reinforced concrete beam, and the prestressed steel bars 9 are mainly arranged in the horseshoe-shaped structure at the bottom of the T-shaped beam. Since the original design was based on the 20-grade load standard for automobiles, the load-carrying capacity could not meet the standard of super-20-grade vehicles for actual traffic, so it needed to be reinforced to increase its bearing capacity. If the reinforcement scheme adopts the "construction method of prestressed tensioning and anchoring of high-strength composite materials" with the patent number ZL021...

Embodiment 2

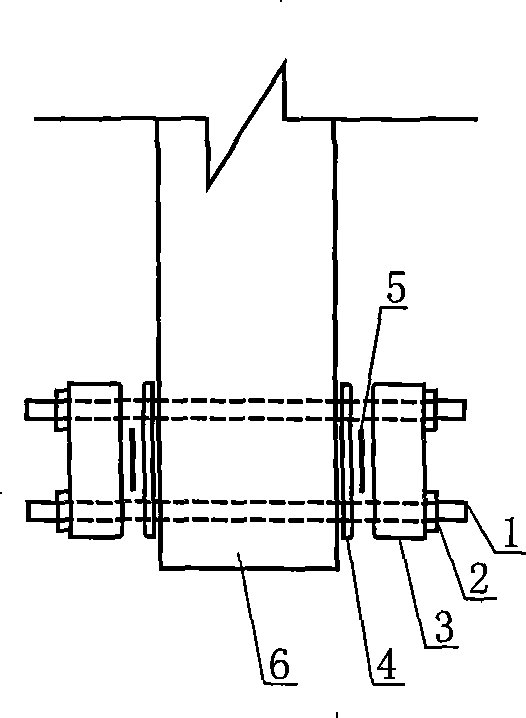

[0044] As shown in Figures 7 to 9, a construction method for reinforcing a pine square engineering structure with a length of 5 meters, a width of 0.3 meters, and a thickness of 0.2 meters with basalt fiber composite material sheets on both sides.

[0045] In many wooden structures, relatively dense wood is often used as a tension member, such as the lower chord of a wooden truss structure. There is a tension-bearing pine square 10, which is 5 meters long, 0.3 meters wide, and 0.2 meters thick. According to the needs of use, its ability to withstand tension must be improved. The method of pasting steel plates on its surface can improve its tensile strength. , but the cost of anticorrosion of steel is high and maintenance is difficult. Using the method of the present invention, using basalt fiber composite material sheet (abbreviated as BFRP sheet) 17 double-sided reinforced pine squares can also improve its tensile capacity, and the construction is convenient. Fast, in additio...

Embodiment 3

[0058] Such as Figure 10 , 11 Shown, a kind of double-sided reinforcement with glass fiber composite material sheet is a construction method for a brick wall engineering structure with a height of 3200 mm, a width of 3000 mm, and a thickness of 240 mm.

[0059] In many masonry structures (brick masonry, masonry masonry, etc.), due to their long service life or poor quality of masonry, the seismic performance of masonry structures is weak and seismic reinforcement is required. An existing brick wall needs to be reinforced against earthquakes, and its dimensions are 3200mm high, 3000mm wide and 240mm thick. If external prestressed steel bars are used for seismic reinforcement, there are problems of anti-corrosion of the prestressed steel bars and high maintenance costs in the later period. The method of the present invention can overcome this difficulty. Adopt the concrete construction steps of construction method of the present invention as follows:

[0060] (1) Bottom corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com