A heat treatment method for high-strength and toughness hot-formed steel sheets for automobiles

A heat treatment method and high-strength toughness technology, which is applied in the field of heat treatment of high-strength and toughness hot-formed steel sheets for automobiles, can solve the problems of poor plasticity and high strength, and achieve the effects of improving elongation, improving toughness, and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

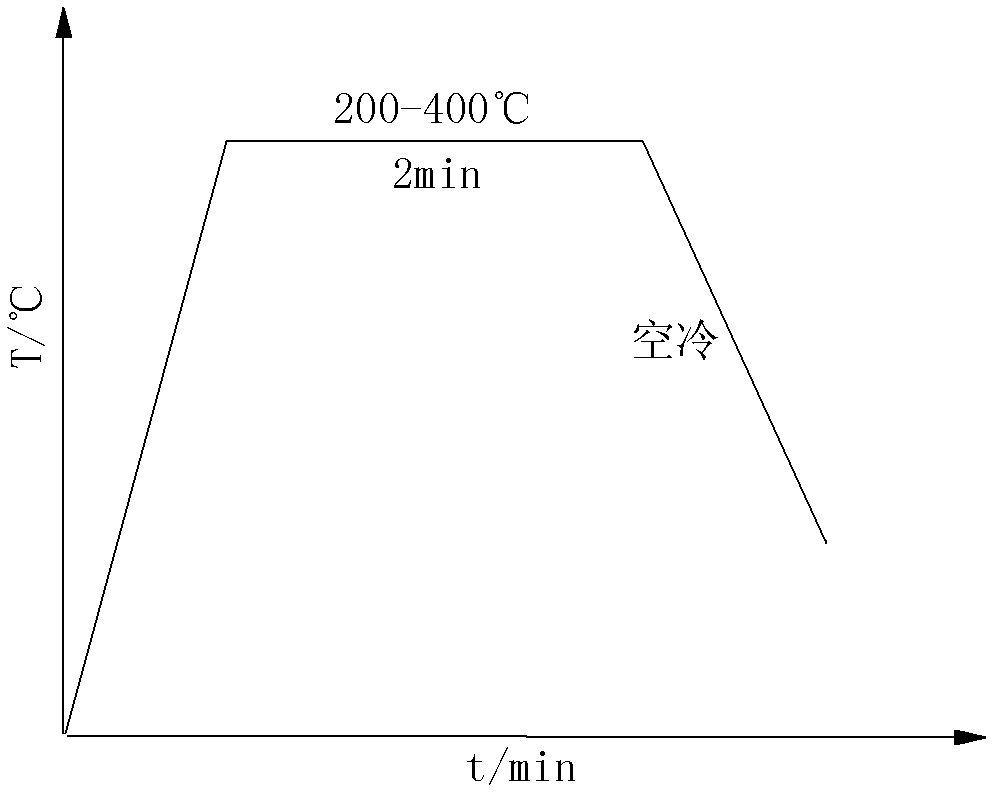

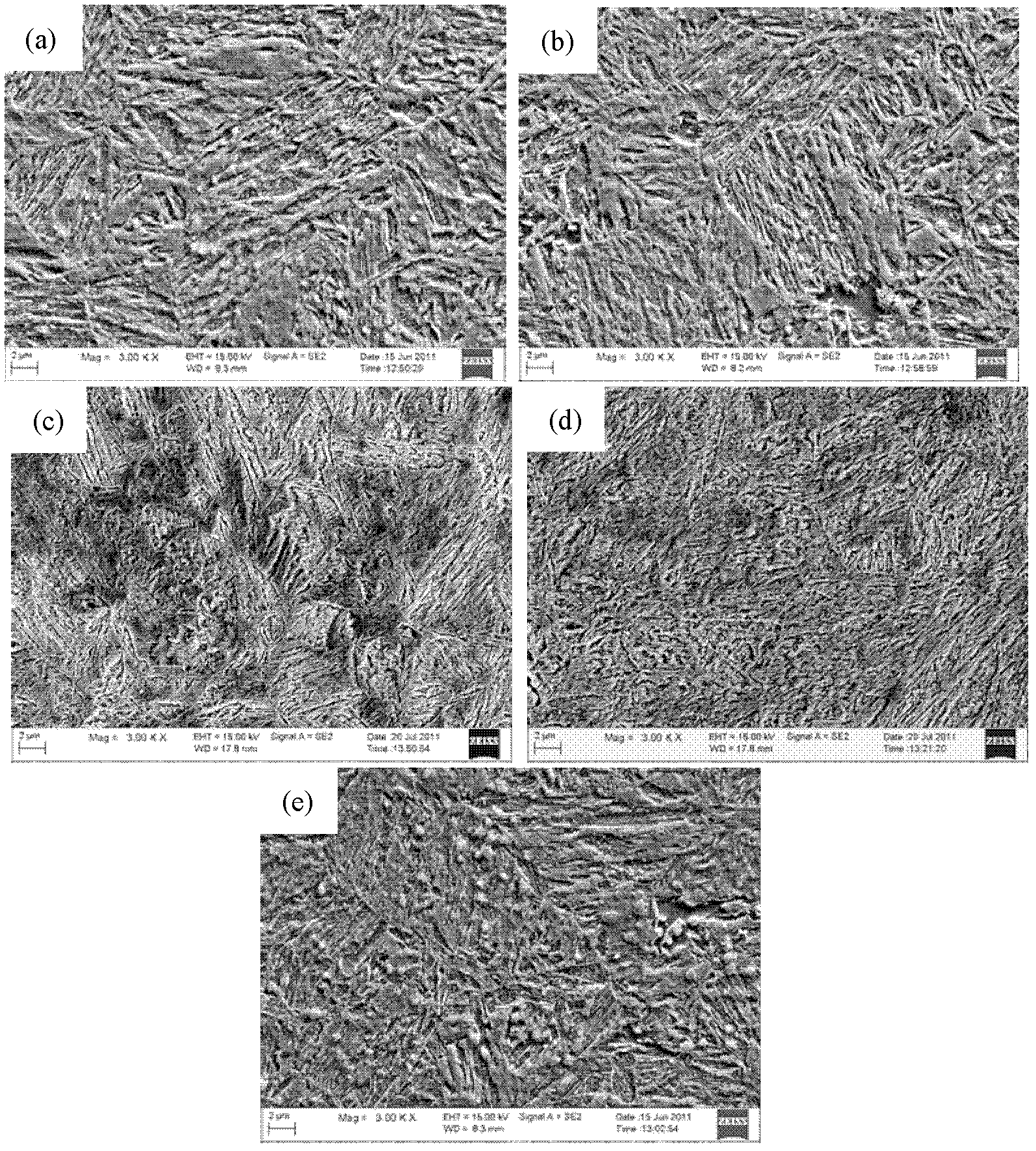

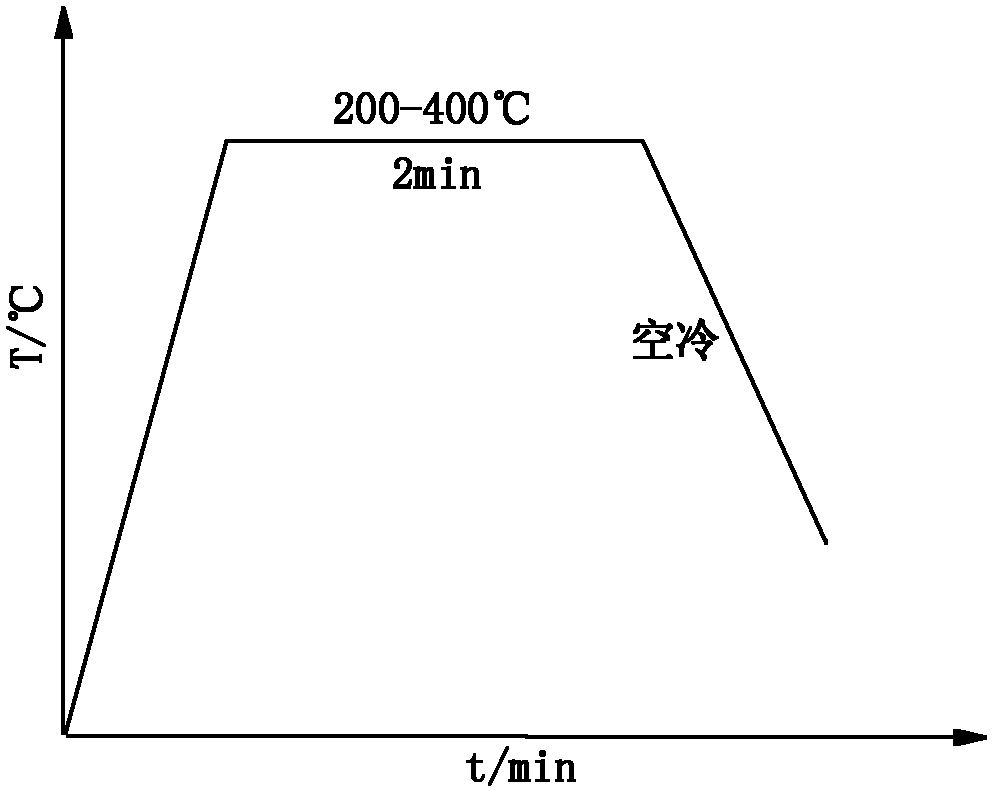

[0026] The hot-formed steel plate was kept at 200 °C for 2 min, and then air-cooled to room temperature, such as figure 1 As shown, the mechanical properties and microstructure are shown in Table 2 and figure 2 (a) shown.

Embodiment 2

[0028] The hot-formed steel plate was kept at 250 °C for 2 min, and then air-cooled to room temperature, such as figure 1 As shown, the mechanical properties and microstructure are shown in Table 2 and figure 2 (b) shown.

Embodiment 3

[0030] The hot-formed steel plate was kept at 300 °C for 2 min, and then air-cooled to room temperature, such as figure 1 As shown, the mechanical properties and microstructure are shown in Table 2 and figure 2 (c) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com