A processing method of titanium alloy closing end

A processing method, titanium alloy technology, applied in the aerospace field, can solve problems such as inability to process, large residual stress, bulging, etc., and achieve the effects of improving product qualification rate, good molding quality, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Processing of Φ1240 Titanium Alloy Hemispherical Head

[0020] ①. Fabrication of blanks: Select 18mm thick titanium alloy plates with a diameter of Φ1800mm for blanking, and turn the periphery to complete the production of blank 6.

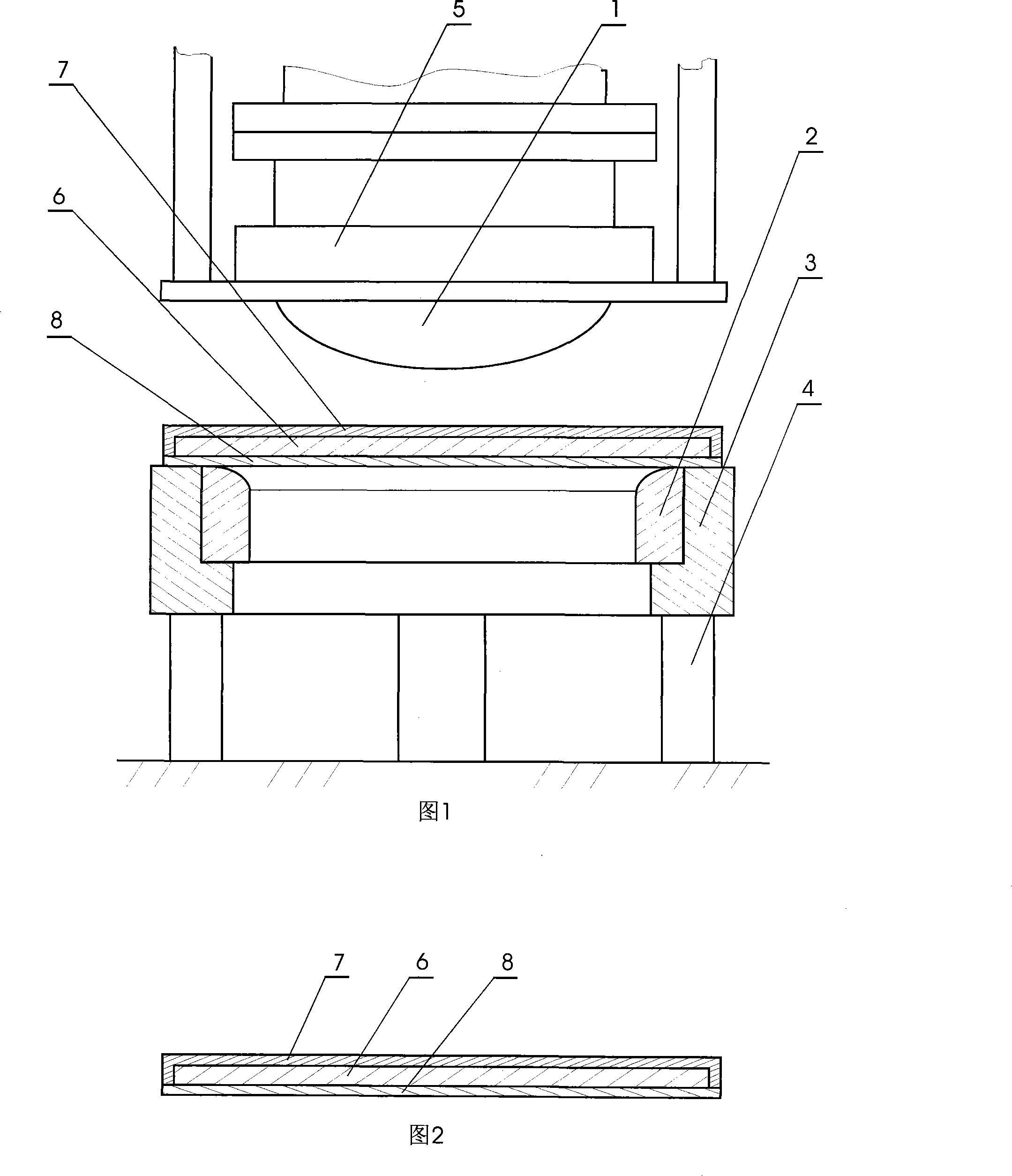

[0021] ②. Constituent components: place the material piece 6 on one side in the groove plate 7 corresponding in size and shape, cover the other side of the material piece 6 with a cover plate 8 corresponding in size and shape, and weld the cover plate 8 and the periphery of the groove plate 7 , making up the component.

[0022] ③. Determine the punching die: select the outer diameter of the punch as Φ1207mm; the inner diameter of the pull ring 2 is Φ1325mm; the punch 1 is fixed on the guide post of the punch press, the pull ring 2 is installed in the seat ring 3, and the seat ring 3 is fixed on the seat pier 4 On, the seat pier 4 is fixed on the workbench of the punch press.

[0023] ④, Heating, stamping and forming: put the component int...

Embodiment 2

[0027] Hot Stamping Processing of Φ330 Titanium Alloy Hemispherical Head

[0028] ①. Fabrication of blanks: select 8 mm thick titanium alloy plates with a diameter of Φ540 mm for blanking, and turn the periphery to complete the production of blank 6.

[0029] ②. Constituent components: place the material piece 6 on one side in the groove plate 7 corresponding in size and shape, cover the other side of the material piece 6 with a cover plate 8 corresponding in size and shape, and weld the cover plate 8 and the periphery of the groove plate 7 , making up the component.

[0030] ③. Determine the punching die: select the outer diameter of the punch as Φ300mm; the inner diameter of the pull ring 2 is Φ360mm; the punch 1 is fixed on the guide post of the punch press, the pull ring 2 is installed in the seat ring 3, and the seat ring 3 is fixed on the seat pier 4 On, the seat pier 4 is fixed on the workbench of the punch press.

[0031] ④, Heating, stamping and forming: Put the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com