Microstructural optimization of automotive structures

a microstructure optimization and automotive technology, applied in the field of microstructure optimization of automotive structures, can solve the problems of not being able to use the currently known hot stamping process, and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

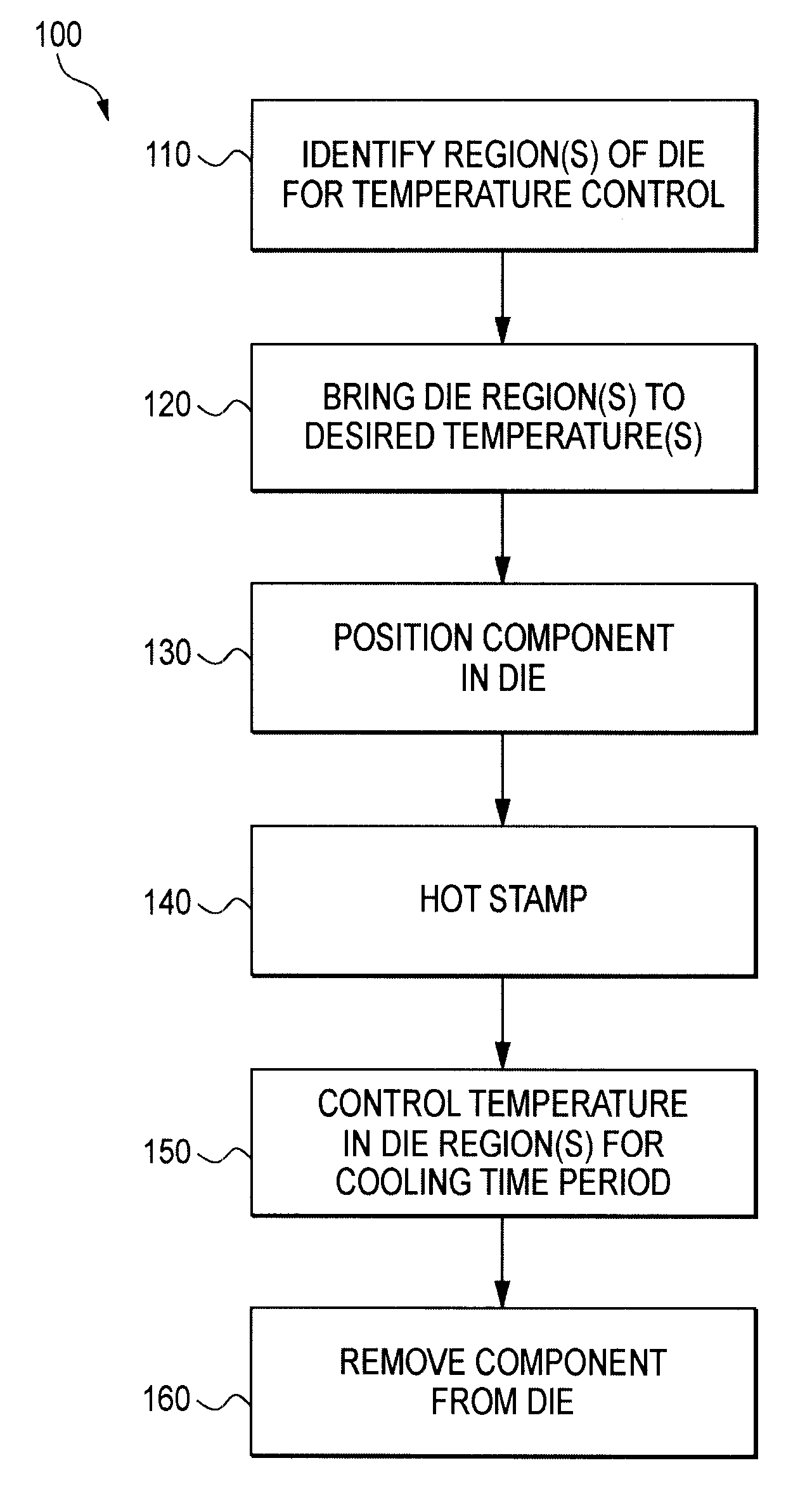

Method used

Image

Examples

Embodiment Construction

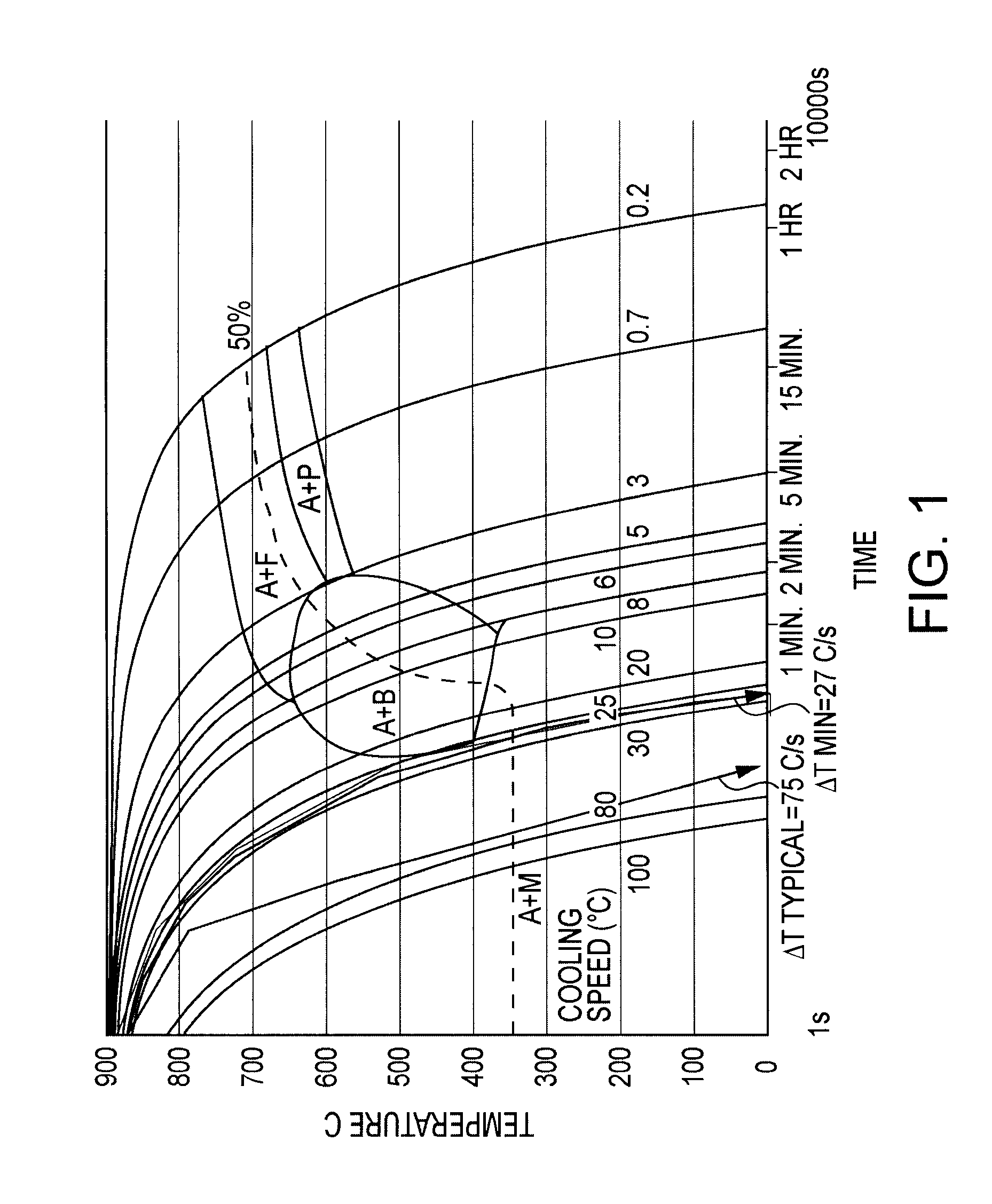

[0022]If a sample of steel is heated in a furnace, at a high enough temperature, it will enter an austenite (A) phase, as depicted on its corresponding phase diagram. In the austenite phase, the iron atoms in the steel are arranged in a face centered cubic (FCC) structure.

[0023]When cooled from this phase, the steel will enter a phase where both ferrite (F) and austenite co-exist. The ferrite phase is a body centered cubic (BCC) structure and cannot dissolve as much of the interstitial carbon as the austenite phase. Therefore, carbon in the regions that are transforming to ferrite must diffuse to the still existing austenite regions, thereby enriching these regions. A phase diagram allows the prediction of how much ferrite and austenite exist, as well as the carbon composition of each, when the phases are in equilibrium at any temperature and composition.

[0024]For most steels, below 727° C., the remaining austenite phase (which is of the eutectoid composition, 0.77 weight percent (w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com