Hot stamping forming method for variable strength distribution strong-strength steel plate part

A technology of hot stamping and high-strength steel, applied in the field of hot-stamping of high-strength steel sheet parts, can solve the problems of effective adjustment of strength, inability to obtain reasonable strength distribution, etc., to achieve smooth strength distribution, ideal overall mechanical properties, and simple mold structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

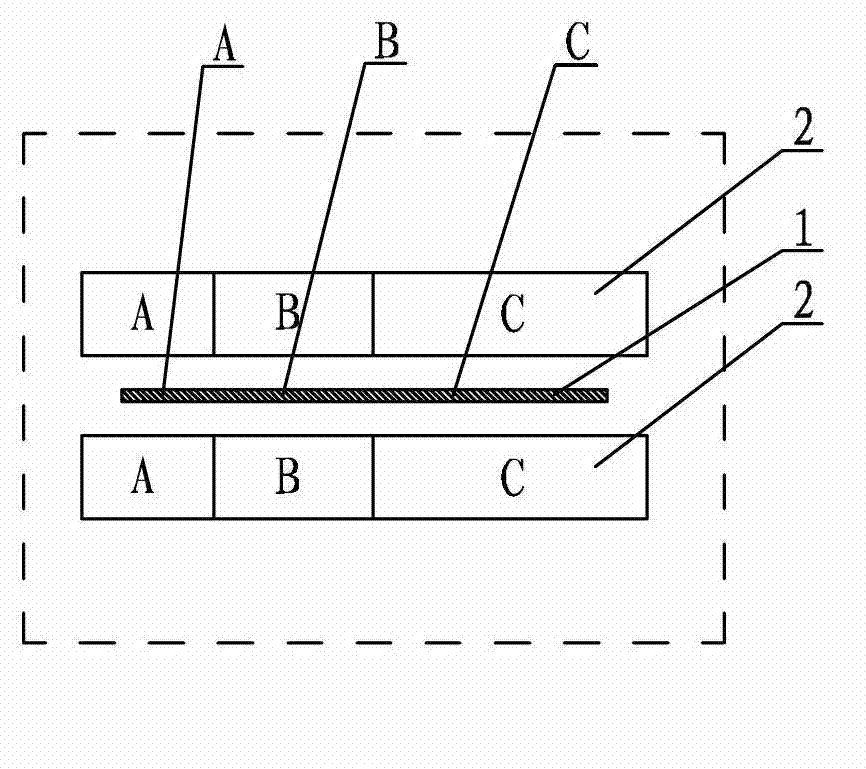

[0013] Specific implementation mode one: combine Figure 1 ~ Figure 3 Specifically illustrate the implementation steps of this embodiment:

[0014] Step 1. Put the high-strength steel slab 1 to be formed into the heater 2. The high-strength steel slab 1 is divided into several areas along the length direction. The several areas are respectively the first area A, the second area B and the third area C. The heater 2 The corresponding zone 1 A, zone 2 B and zone 3 C use different or the same heating temperature for zone control, and heater 2 corresponds to zone 1 A, zone 2 B and zone 3 C for zone control using different or the same heating time ;

[0015] Step 2, quickly transfer the heated high-strength steel slab 1 to the forming mold 3 within 3 to 5 seconds, quickly close the forming mold 3 and complete the forming of the high-strength steel slab 1 within 1 to 3 seconds;

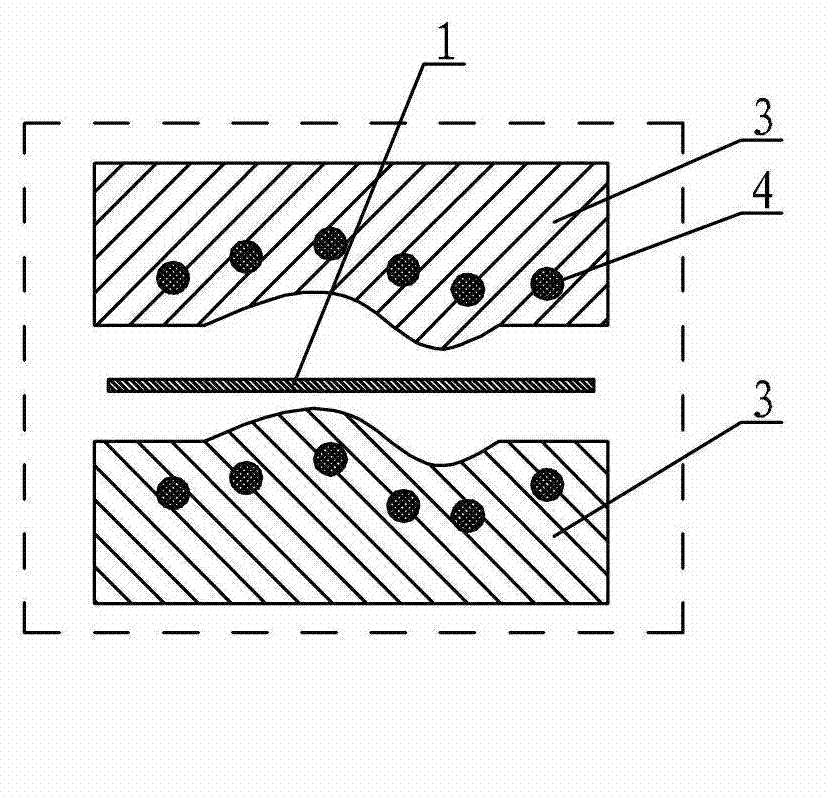

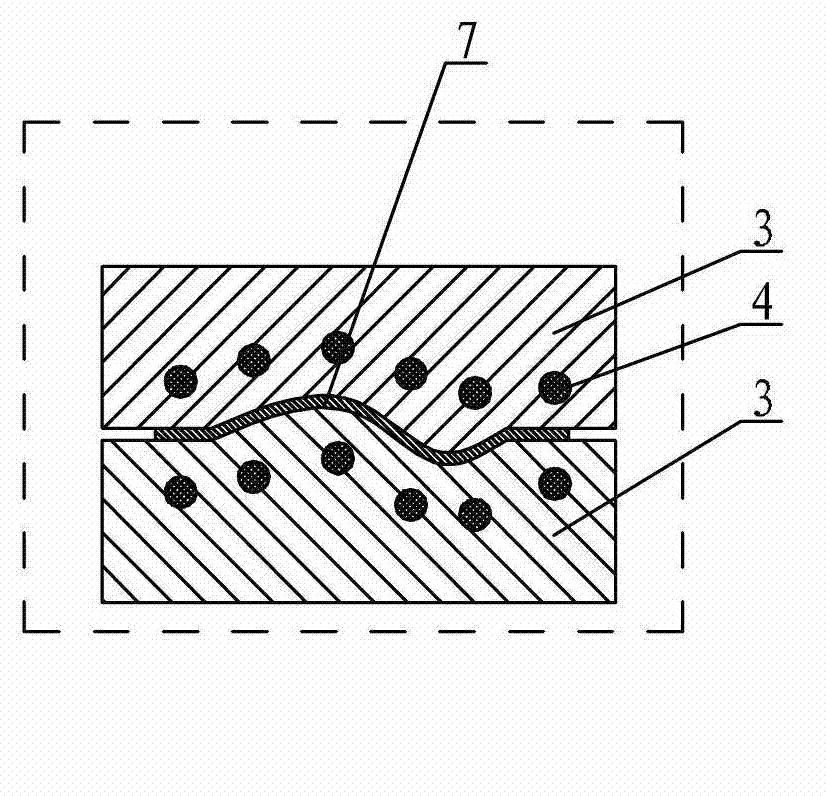

[0016] Step 3, keeping the forming mold 3 closed, passing cooling water into the cooling hole 4 on the ...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the first zone A, the second zone B and the third zone C corresponding to the heater 2 in step one of this embodiment adopt different heating temperatures and the same heating time for zone control, and the high-strength steel slab in step one 1 The heating temperature for areas with high strength requirements is 850°C to 1000°C, the heating temperature for areas with low strength requirements is 700°C to 850°C, and the heating time for areas with high strength requirements and areas with low strength requirements is 3 minutes to 6 minutes. The division of areas with high strength requirements and areas with low strength requirements is based on the needs of parts. In this embodiment, different austenitization degrees are obtained by controlling the heating temperature of different regions on the high-strength steel slab 1 . During implementation, the above-mentioned purpose can be ac...

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the heating temperature of the high-strength steel slab 1 in step 1 of this embodiment is 900°C for the region with high strength requirement, 750°C for the region with low strength requirement, and the region with high strength requirement and the region with low strength requirement The heating time is 5min. In this embodiment, different austenitization degrees are obtained by controlling the heating temperature of different regions on the high-strength steel slab 1 . During implementation, the above-mentioned purpose can be achieved only by performing zone temperature control on the heater 2, and the method is simple and feasible. Other steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com