SMA (styrene maleic anhydride) on-site thermal regenerated asphalt mixture

A technology of asphalt mixture and thermal regeneration, which is applied in the field of asphalt recycled materials, can solve environmental pollution and other problems, and achieve the effects of avoiding environmental pollution, saving resources, and making up for aging and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

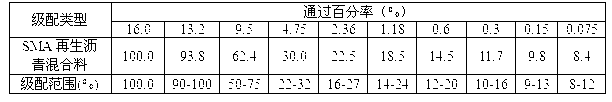

[0013] Composition of SMA recycled asphalt mixture (parts by weight):

[0014] 1. Recycled old materials: 950 parts of RAP material (SMA asphalt pavement milling material) (about 5.8% asphalt ratio), 0.52 parts of asphalt rejuvenator (Tianke SZS rejuvenator) (addition ratio depends on the aging degree of asphalt in RAP material) , up to 1% by weight of bitumen in the RAP material);

[0015] 2. Newly added asphalt mixture: 20 parts of 1# material, 20 parts of 2# material, 5 parts of 4# material, 5 parts of mineral powder, 2.9 parts of SBS modified asphalt, and 0.15 parts of lignin fiber.

[0016] In-house preparation process:

[0017] 1) Mix the newly added asphalt mixture indoors, and put it in an oven at 165°C to keep warm after mixing;

[0018] 2) Mix the dispersed RAP evenly at a temperature of 135°C, then add asphalt regenerant and mix for 30s;

[0019] 3) Add SBS modified asphalt to RAP and mix for 30s;

[0020] 4) Add the new asphalt mixture that has been mixed in th...

Embodiment 2

[0025] Composition of SMA recycled asphalt mixture (parts by weight):

[0026] 1. Recycled old materials: 850 parts of RAP (SMA asphalt pavement milling material) (asphalt ratio 5.8%), newly added SBS modified asphalt 0.85 parts (the addition amount is determined according to the ratio of asphalt in the RAP material, so that the asphalt in the recycled old material ratio between 5.8% and 6.0%);

[0027] 2. Newly added asphalt mixture: 60 parts of 1# material, 60 parts of 2# material, 15 parts of 4# material, 15 parts of mineral powder, 8.85 parts of SBS modified asphalt, and 0.45 parts of lignin fiber.

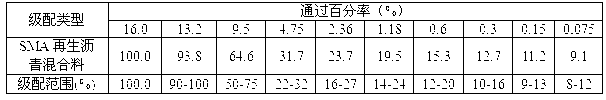

[0028] The indoor preparation process is the same as in Example 1, and the mineral material gradation of SMA on-site thermally recycled asphalt mixture is shown in Table 2

[0029] Table 2 Gradation composition of mineral materials

[0030]

Embodiment 3

[0032] Composition of SMA recycled asphalt mixture (parts by weight):

[0033] 1. Recycled old materials: 900 parts of RAP (SMA asphalt pavement milling material) (asphalt ratio 5.8%), 1.8 parts of SBS modified asphalt;

[0034] 2. Newly added asphalt mixture: 50 parts of 1# material, 30 parts of 2# material, 10 parts of 4# material, 10 parts of mineral powder, 6.0 parts of SBS modified asphalt, and 0.3 parts of lignin fiber.

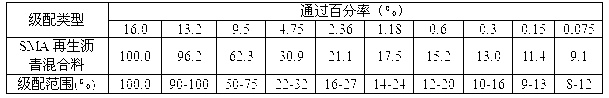

[0035] The indoor preparation process is the same as in Example 1, and the mineral material gradation of SMA on-site thermally recycled asphalt mixture is shown in Table 3.

[0036] Table 3 Grading composition of mineral materials

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com