Preparation method of nylon-6 grafting modified carbon nano tubes

A carbon nanotube and graft modification technology is applied in the field of preparation of nylon 6 graft modified carbon nanotubes, which can solve the problems of dangerous and toxic use of reagents and damage to the structure of carbon nanotubes, and achieve the effect of improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

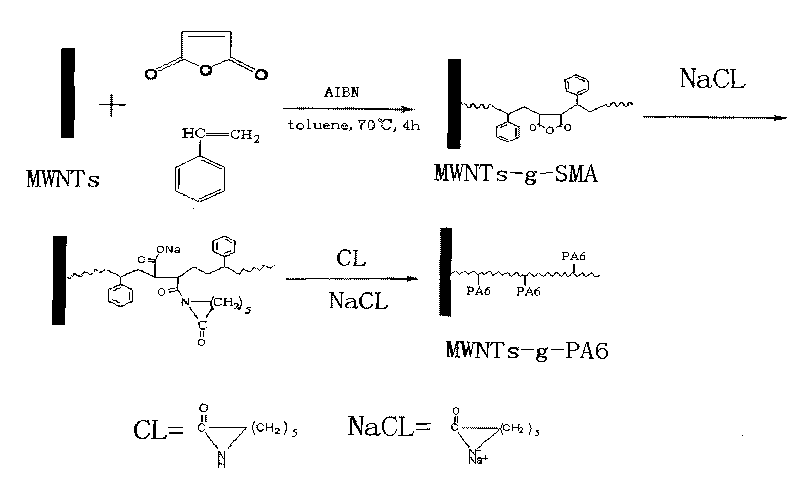

[0031] Such as figure 1 Shown, a kind of preparation method of nylon 6 grafted modified carbon nanotubes, the method comprises the following steps:

[0032] (1) Preparation of styrene maleic anhydride grafted multi-walled carbon nanotubes (MWNTs-g-SMA):

[0033] Mix MWNTs, styrene, maleic anhydride, and toluene in a weight ratio of 0.1:12.5:10:200, and then ultrasonically disperse them for 0.5 hours, then put them into a reaction bottle, and then add 0.5 times the weight of MWNTs as a free radical initiator azo After mixing diisopropyl cyanide evenly, react at a constant temperature of 50°C for 1 hour under the condition of stirring. After the reaction, the toluene is removed by suction filtration, and the obtained crude product is dispersed in acetone, washed with acetone, and suction filtered. After five times, the The obtained filter cake was vacuum dried at 60°C for 24 hours to obtain MWNTs-g-SMA;

[0034] (2) Preparation of nylon 6 grafted modified carbon nanotubes (MWN...

Embodiment 2

[0037] see figure 1 Shown, a kind of preparation method of nylon 6 grafted modified carbon nanotubes, the method comprises the following steps:

[0038] (1) Preparation of MWNTs-g-SMA:

[0039] Mix MWNTs, styrene, maleic anhydride, and toluene in a weight ratio of 0.3:12.5:10:200, and carry out ultrasonic dispersion for 0.8 hours, then put them into a reaction bottle, and then add 0.7 times the weight of MWNTs. Benzoyl, after mixing evenly, reacted at a constant temperature of 65°C for 2.5 hours under the condition of stirring. After the reaction, the toluene was removed by suction filtration. The filter cake was vacuum dried at 66°C for 24 hours to obtain MWNTs-g-SMA;

[0040] (2) Preparation of MWNTs-g-PA6:

[0041]Under the protection of nitrogen, the prepared MWNTs-g-SMA is added to the caprolactam monomer that has been strictly dehydrated, and the amount of caprolactam added is 150 times the weight of MWNTs-g-SMA, and then 20% of the weight of the caprolactam monomer i...

Embodiment 3

[0043] see figure 1 Shown, a kind of preparation method of nylon 6 grafted modified carbon nanotubes, the method comprises the following steps:

[0044] (1) Preparation of MWNTs-g-SMA:

[0045] Mix MWNTs, styrene, maleic anhydride, and toluene in a weight ratio of 0.5:12.5:10:200, and then ultrasonically disperse them for 1 hour, then put them into a reaction bottle, and then add 0.95 times the weight of MWNTs as a free radical initiator azo Diisobutylcyanide, after mixing evenly, reacted at a constant temperature of 72°C for 4 hours under stirring conditions. After the reaction was completed, the toluene was removed by suction filtration, and the obtained crude product was dispersed in acetone, washed with acetone, and suction filtered. After repeated five times, the The obtained filter cake was vacuum dried at 70°C for 24 hours to obtain MWNTs-g-SMA;

[0046] (2) Preparation of MWNTs-g-PA6:

[0047] Under the protection of nitrogen, the prepared MWNTs-g-SMA is added to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com