Water-based inner printing ink coated with PE and PP and preparation method thereof

A water-based, flow-coating technology, applied in the direction of ink, household utensils, pigment paste, etc., can solve the problems of large color difference, poor abrasion resistance and heat resistance, substrate, ink layer and plastic film are easy to separate or fall off, etc. Achieve excellent wear resistance, not easy to separate or fall off, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

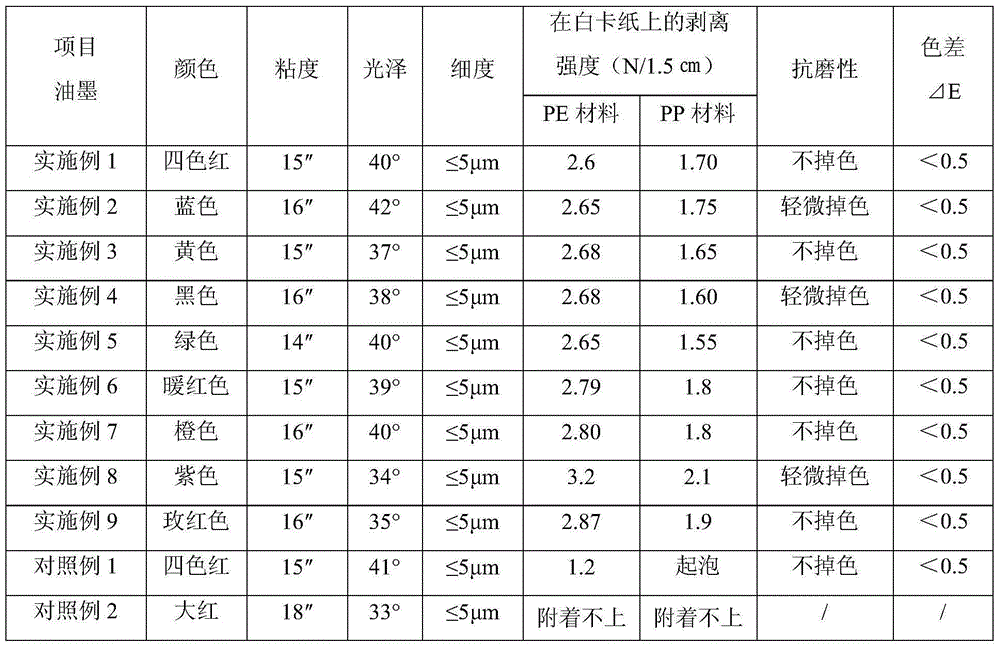

Examples

Embodiment 1

[0032] The water-based PE and PP water-based lining ink of this embodiment is composed of the following components by weight: 25.9 parts of varnish, 70 parts of water-based color paste, 0.1 part of defoamer and 4 parts of deionized water; The ink consists of the following components by weight: 62 parts of styrene-acrylic non-film-forming emulsion, 30 parts of acrylic resin solution, 3 parts of wax emulsion, 4 parts of film-forming aids, 0.2 part of organic amine, 0.5 part of wetting agent, 0.2 part of foaming agent and 0.1 part of preservative; water-based color paste is composed of the following components by weight: 25 parts of acrylic resin solution, 2 parts of wetting and dispersing agent, 32.8 parts of deionized water, 40 parts of pigment, and 0.1 part of defoaming agent And 0.1 part of preservative.

[0033] Specifically, the styrene-acrylic non-film-forming emulsion is BasfJoncrly90 with a solid content of 44%, a Tg value of 110°C, and an acid value of 76mgKOH / g; the acryl...

Embodiment 2

[0042] The water-based PE and PP water-based lining ink of this embodiment is composed of the following components by weight: 29.9 parts of varnish, 70 parts of water-based color paste and 0.1 part of defoamer; among them: varnish and Example 1 Same; the water-based color paste is composed of the following components by weight: 22.7 parts of acrylic resin solution, 1.5 parts of wetting and dispersing agent, 30.8 parts of deionized water, 45 parts of pigment, 0.1 part of defoamer and 0.1 part of preservative.

[0043] In the above water-based color paste, except that the pigment is PY14, the other components are the same as in Example 1, and the flow-coated PE and PP water-based lining ink of this example can be prepared by referring to the preparation method of Example 1.

Embodiment 3

[0045] The water-based PE and PP water-based lining ink of this embodiment is composed of the following components by weight: 27.9 parts of varnish, 70 parts of water-based color paste, 0.1 part of defoamer and 2 parts of deionized water; The ink is composed of the following components by weight: 58 parts of styrene-acrylic non-film forming emulsion, 35 parts of styrene-maleic anhydride resin solution, 3 parts of wax emulsion, 3 parts of film-forming aids, 0.2 parts of organic amine, wetting 0.5 part of antifoaming agent, 0.2 part of anti-foaming agent and 0.1 part of preservative; water-based color paste is composed of the following components by weight: 22.7 parts of acrylic resin solution, 1.5 parts of wetting and dispersing agent, 30.8 parts of deionized water, 45 parts of pigment, 0.1 part of defoamer and 0.1 part of preservative.

[0046] The non-film-forming emulsion except for styrene-acrylic acid is DSMA-2091; the styrene-maleic anhydride resin solution is SMA1000p; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com