Preparation method for antistatic super hydrophobic composite coating

A composite coating and super-hydrophobic technology, applied in the field of nanomaterials, can solve the problems of multi-toxic reaction steps, long reaction time, and many steps, and achieve the effect of simple operation, simple raw materials, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

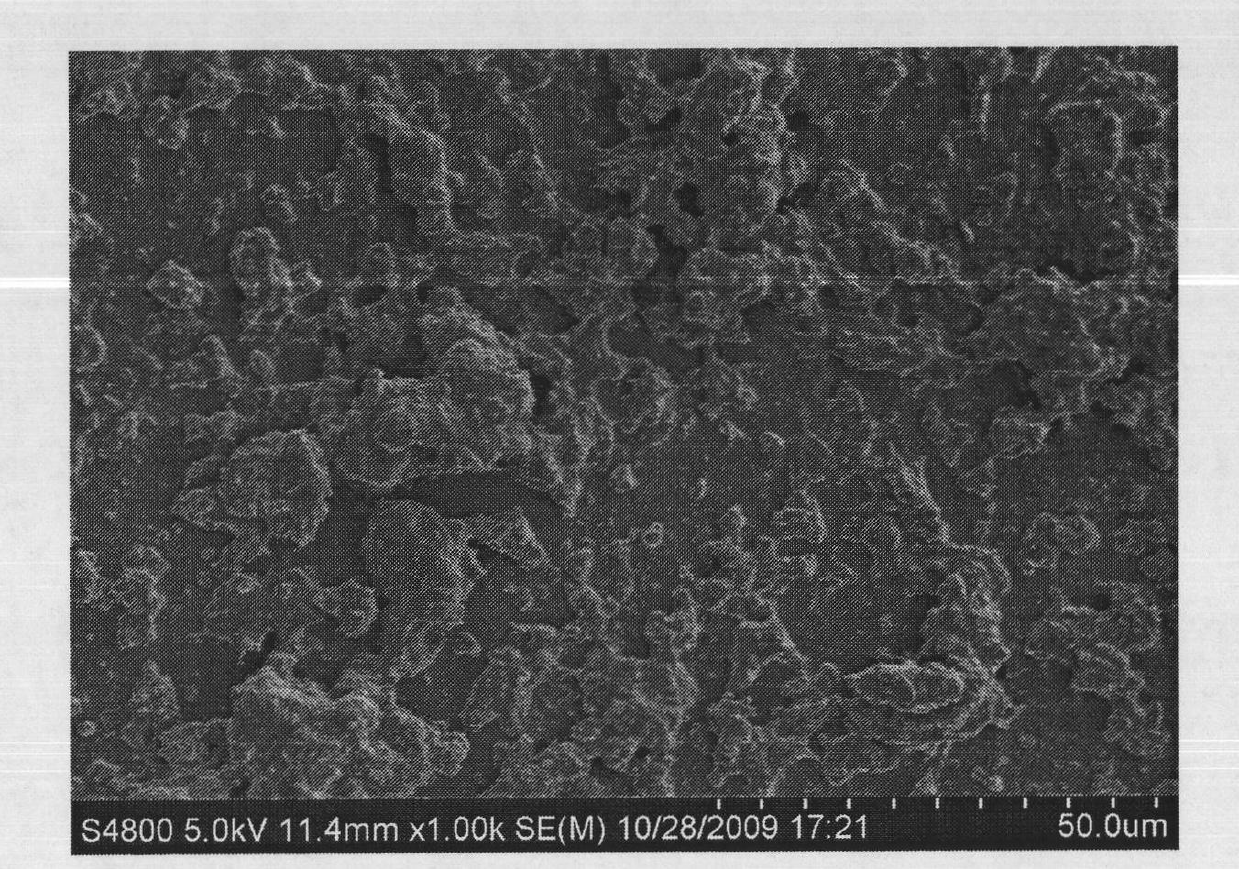

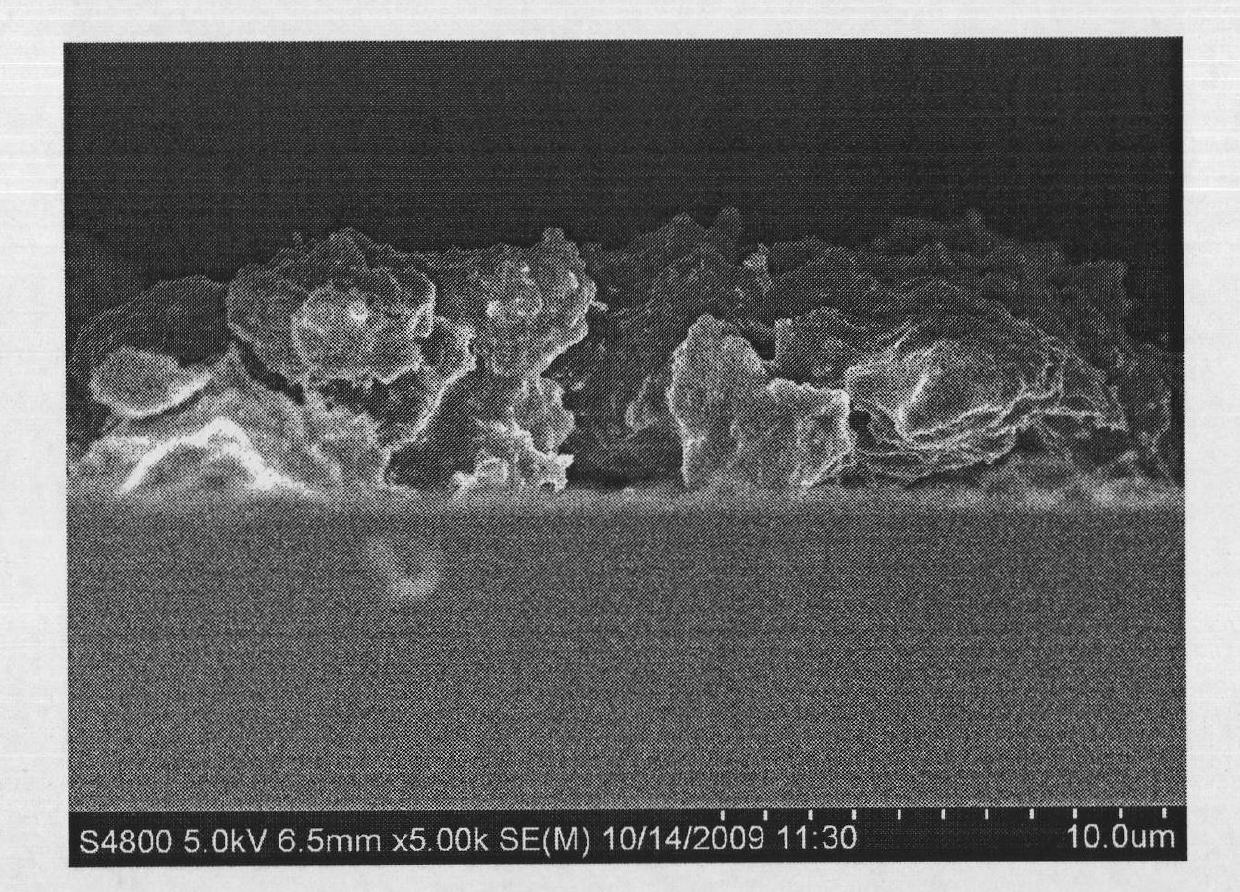

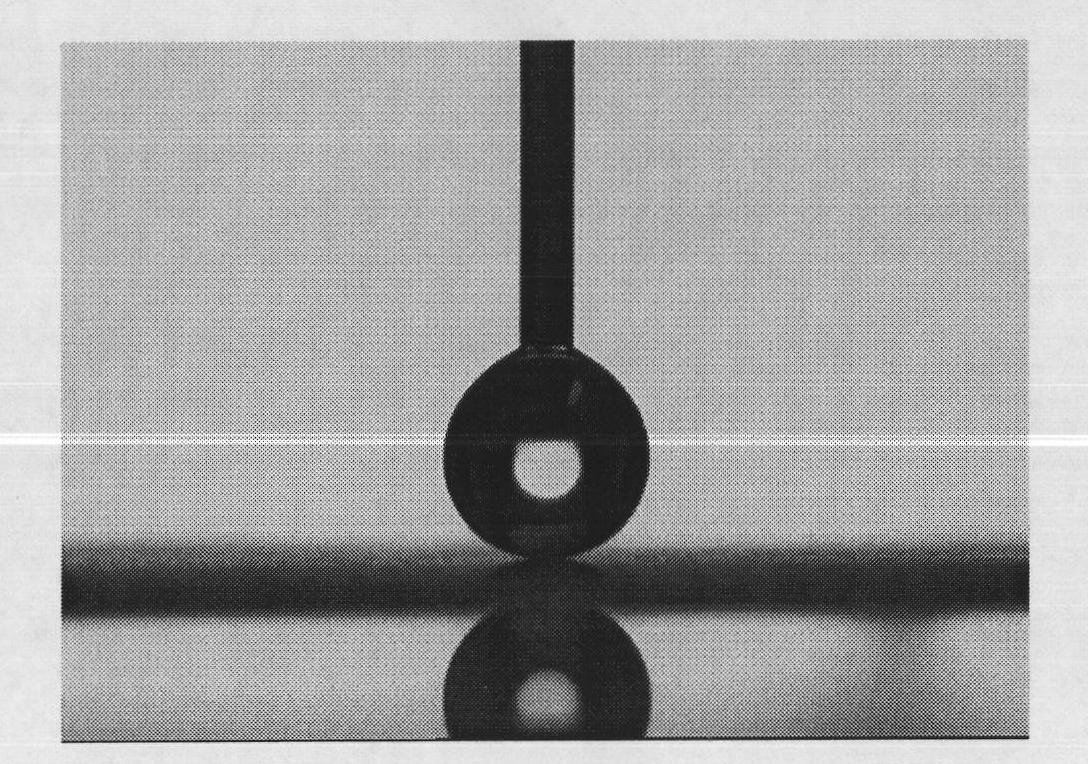

[0022] Dissolve 0.6 g of styrene-maleic anhydride alternating copolymer in 30 ml of ethanol, add 1 g of carbon nanotubes, stir and mix for 15 minutes and ultrasonic for 5 minutes, mix 1.3 g of aminopropyltriethoxysilane with 0.7 g Add ethyl orthosilicate to the system, add 2.6 grams of ammonia water, stir evenly, and react for 0.5 hours; Spray it on a glass substrate, and after aging for 12 hours, heat it to 180° C. for 1 hour to obtain the final product. The glass is first soaked in a mixed solution of hydrogen peroxide and concentrated sulfuric acid with a weight ratio of 1:1 for 0.5 hours, then washed with deionized water and dried in the air. figure 1 is a scanning electron micrograph of the composite coating surface. figure 2 is a scanning electron micrograph of the composite coating section. image 3 It is the static contact angle optical photo of this composite coating, and its static contact angle is 162 ± 3 degrees. Figure 4 It is the rolling angle optical pictur...

Embodiment 2

[0024] Dissolve 0.2 g of styrene-maleic anhydride alternating copolymer in 50 ml of ethanol, add 1.0 g of carbon nanotubes, stir mechanically for 20 minutes and sonicate for 10 minutes, mix 1.0 g of aminopropyltriethoxysilane with 0.5 g Add ethyl orthosilicate to the system, add 26 grams of ammonia water, stir evenly, react for 1 hour, then add 4.0 grams of ethyl orthosilicate and 0.4 grams of heptadecafluorodecyltrimethoxysilane and mix evenly, spray the solution on After aging for 24 hours on the glass substrate, heat treatment at 150°C for 3 hours to obtain the final product. The static contact angle with water is above 160°, the rolling angle is less than 2°, and the surface resistivity is 1.3×10 6 Ω. The glass is first soaked in a mixed solution of hydrogen peroxide and concentrated sulfuric acid with a weight ratio of 1:1 for 2 hours, then washed with deionized water and dried in the air.

Embodiment 3

[0026] Dissolve 1 gram of styrene-maleic anhydride alternating copolymer in a mixed solvent of 20 milliliters of ethanol and 1 milliliter of water, add 1 gram of carbon nanotubes, sonicate for 10 minutes and mechanically stir for 30 minutes, add 2 grams of methyl trimethyl Ethoxysilane, stirred for 48 hours. In addition, 2 grams of ethyl tetrasilicate and 0.5 grams of heptadecafluorodecyltrimethoxysilane were added to the above system to obtain a uniform dispersion; the solution was sprayed on the ceramic substrate, and after aging for 12 hours, heated Heat treatment at 200° C. for 30 minutes to obtain the final product. The static contact angle with water is above 150°, the rolling angle is less than 2°, and the surface resistivity is 4.5×10 6 Ω. The ceramic substrate is soaked in a mixed solution of hydrogen peroxide and concentrated sulfuric acid with a weight ratio of 1:1 for 1 hour, then cleaned with deionized water and dried in air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com