Method for copolymerization of maleic anhydride/conjugated diene

A technology of conjugated diene and maleic anhydride, which is applied in the field of copolymerization of maleic anhydride and butadiene, and maleic anhydride and isoprene, to achieve the effects of easy process control, reduced environmental pollution, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

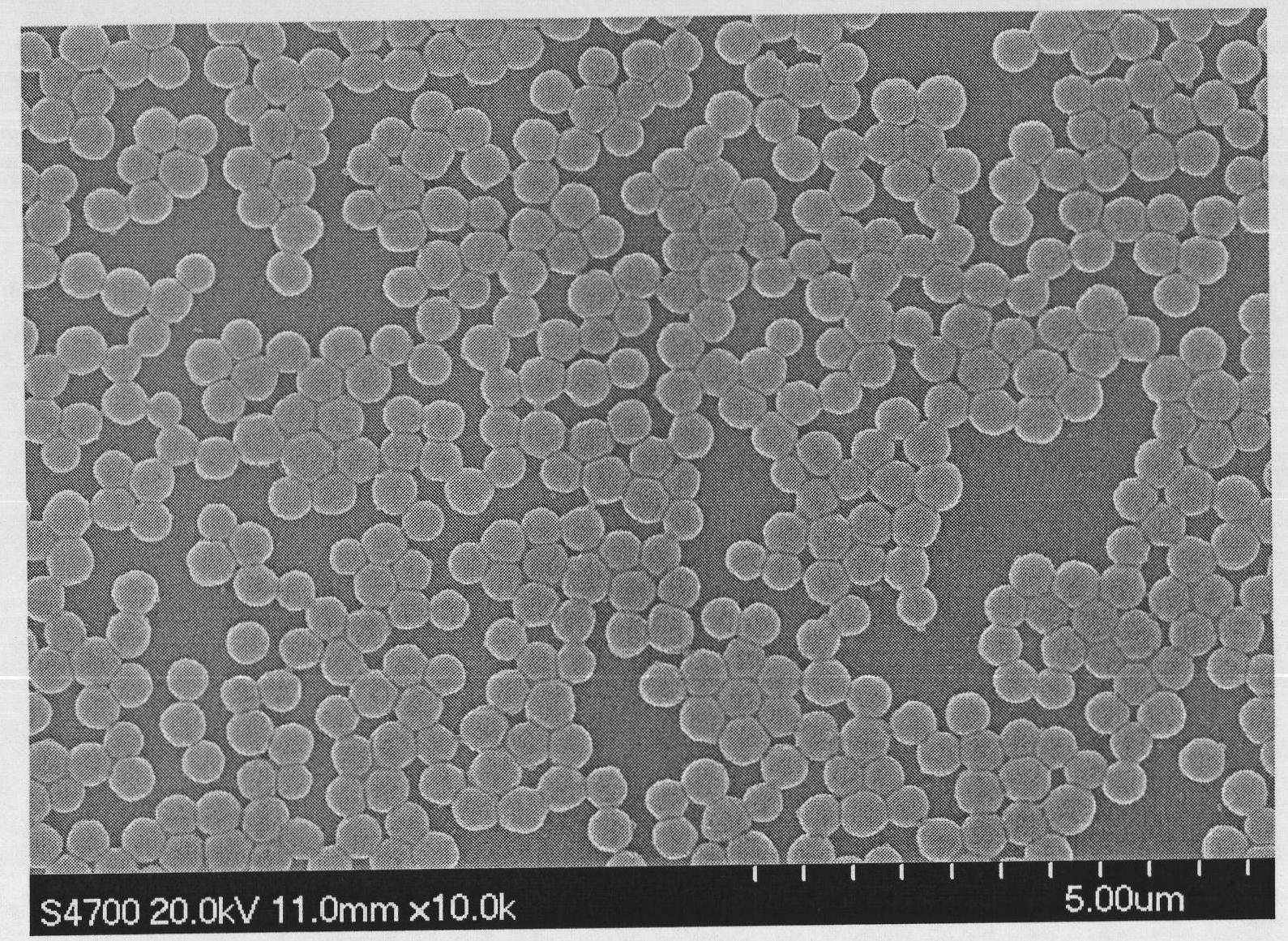

Embodiment 1

[0054] Under the condition of nitrogen protection, after the monomer maleic anhydride and the initiator are added to the medium to fully dissolve, then the monomer conjugated diene is added to dissolve in the system, and the molar ratio of MAn and butadiene is 1:1, wherein MAn 4.903g, butadiene 2.84g; initiator is azobisisobutyronitrile AIBN, 0.03g; medium is isoamyl acetate, 102mL. Heated in a water bath and reacted at a temperature of 60°C for 6 hours to obtain a dispersion system of maleic anhydride and conjugated diene copolymer microspheres, and then centrifuged and vacuum dried to obtain a white powder of maleic anhydride and conjugated diene copolymer microsphere solid. See Table 1 for average particle size (Dn) and dispersion coefficient (U).

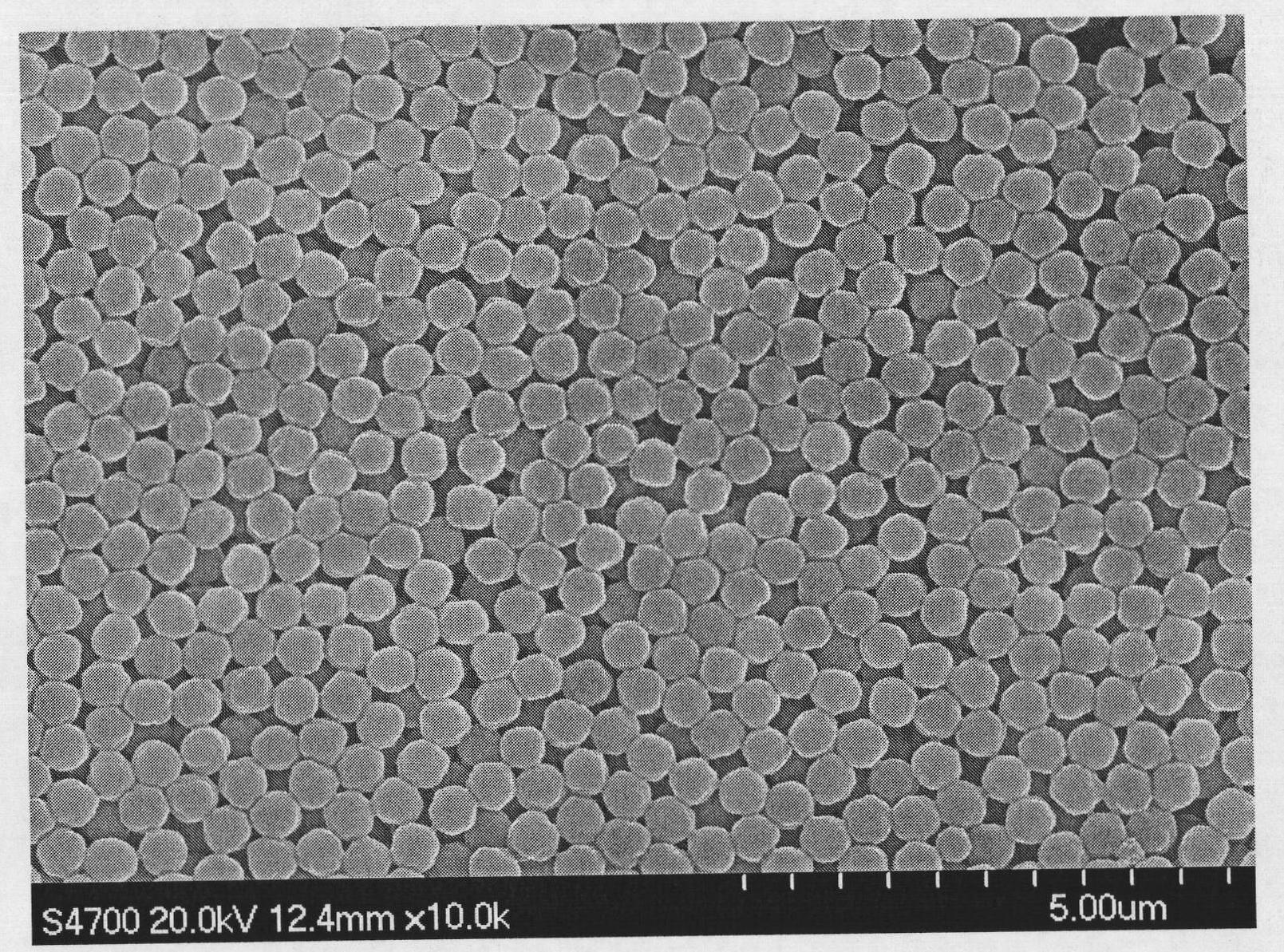

Embodiment 2

[0056] Implementation steps are the same as embodiment 1. The molar ratio of MAn and butadiene is 1:2, wherein MAn is 4.903g, butadiene is 5.55g; the initiator is AIBN, 0.03g; the medium is isoamyl acetate, 98mL. Heated in a water bath and reacted at a temperature of 60° C. for 6 hours, and the average particle diameter (Dn) and dispersion coefficient (U) of the obtained copolymer microspheres are shown in Table 1.

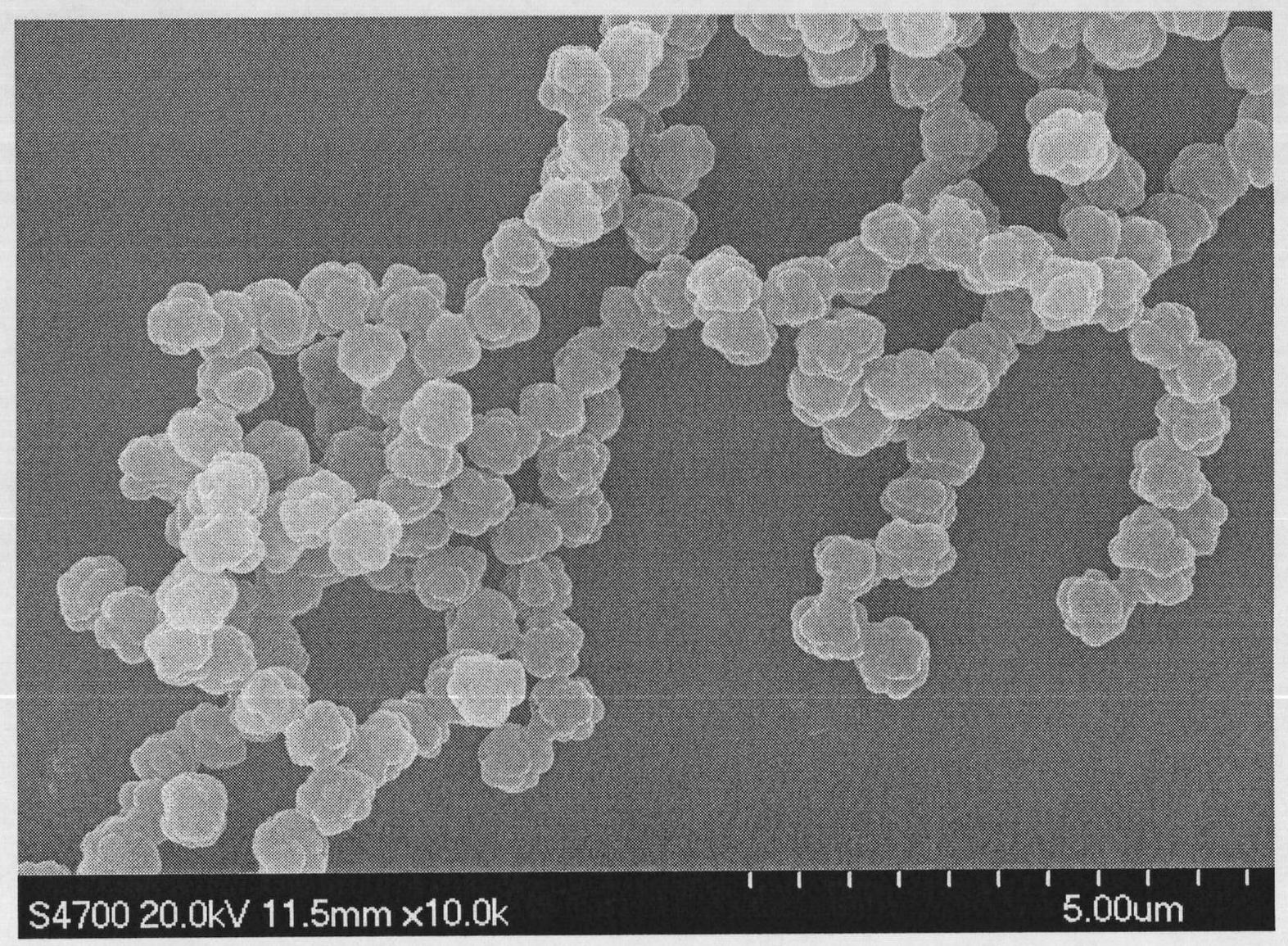

Embodiment 3

[0058] Implementation steps are the same as embodiment 1. The molar ratio of MAn and butadiene is 1:5, wherein MAn is 4.903g, butadiene is 14.73g; the initiator is AIBN, 0.04g; the medium is isoamyl acetate, 86mL. Heated in a water bath and reacted at a temperature of 60° C. for 6 hours, and the average particle diameter (Dn) and dispersion coefficient (U) of the obtained copolymer microspheres are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com