Copolymer containing functional group and prepared by C5 mixture and maleic anhydride, and preparation of copolymer

A functional group, maleic anhydride technology, applied in the field of C5 resource application, can solve the problems of single product type, complicated polymerization method, uneconomical, etc., and achieve the effect of simple process, controllable operation, and reduced reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

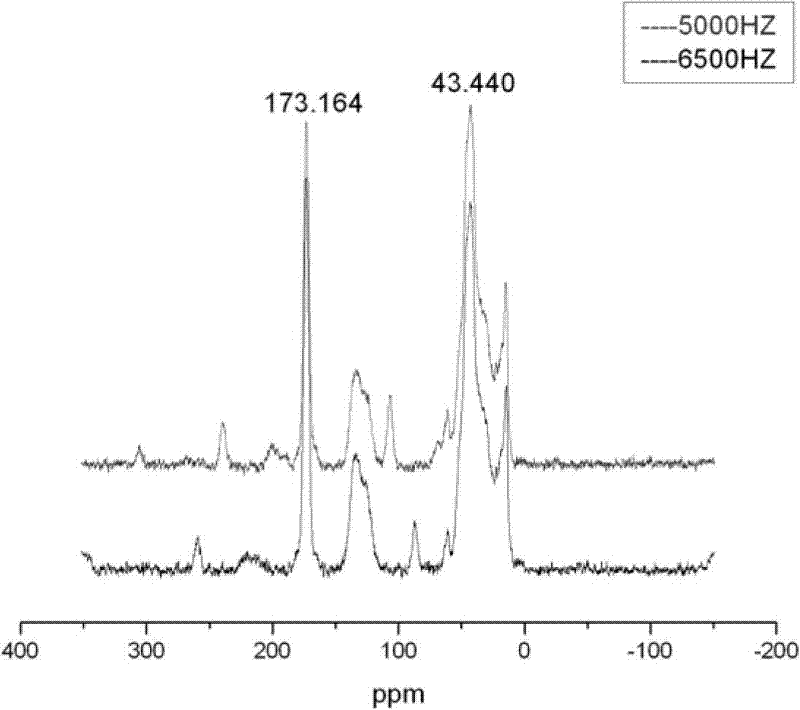

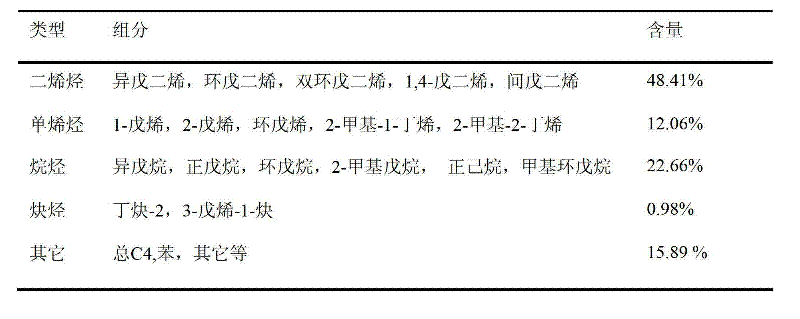

Method used

Image

Examples

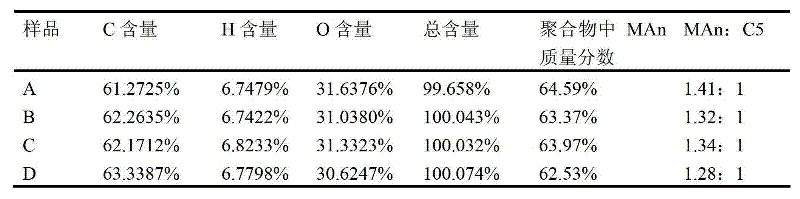

Embodiment 1

[0020] Heated in a water bath at 70°C under the protection of nitrogen, dissolved 2.9434g of maleic anhydride and 0.2174g of azobisisobutyronitrile in 60mL of isoamyl acetate medium, and ultrasonically dissolved to obtain a colorless and transparent solution, then added 2.3426g of C5 mixture, and placed under nitrogen protection After reacting at constant temperature for 7 hours, 3.1025 g of C5 and maleic anhydride (MAn) copolymer was obtained, with a yield of 58.49%.

Embodiment 2

[0022] Heated in a water bath at 80°C under the protection of nitrogen, dissolved 1.9626g of maleic anhydride and 0.1121g of azobisisobutyronitrile in 30mL of isoamyl acetate medium, ultrasonically dissolved to obtain a colorless and transparent solution, then added 1.5612g of C5 mixture, and placed under nitrogen protection After reacting at constant temperature for 7 hours, 2.1571 g of C5 and maleic anhydride (MAn) copolymer was obtained, with a yield of 61.21%.

Embodiment 3

[0024] Heated in a water bath at 90°C under the protection of nitrogen, dissolved 0.9812g of maleic anhydride and 0.0608g of azobisisobutyronitrile in 15mL of isoamyl acetate medium, and ultrasonically dissolved to obtain a colorless and transparent solution, then added 0.7814g of C5 mixture, and placed under nitrogen protection After reacting at constant temperature for 7 hours, 0.9379 g of C5 and maleic anhydride (MAn) copolymer was obtained, with a yield of 53.21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com