Leadless pyroelectric ceramic material and preparation method thereof

A technology of pyroelectric ceramics and ceramic blanks, applied in the field of strontium barium niobate-based lead-free pyroelectric ceramic materials and its preparation, lead-free pyroelectric ceramic materials and its preparation fields, can solve the problem of high material preparation cost, It is unfavorable for popularization and application, and achieves the effect of simple process, low cost and moderate dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, according to the general formula Sr 0.5 Ba 0.5 Nb 2 O 6 [x=0.00, abbreviated as CSBN(0.00)] Weigh the BaCO of the stoichiometric ratio 3 , SrCO 3 And Nb 2 O 5 For each powder, the wet ball milling process is used to make all the powders evenly mixed; the ball milling conditions are: ball milling material, agate balls and absolute ethanol are mixed in a mass ratio of 1:1.2:1.0, and ball milled for 24 hours.

[0031] After drying the obtained mixed powder and sieving through a 40-mesh sieve, it is compacted and synthesized in an atmospheric atmosphere. The synthesis temperature is 1200°C and the synthesis time is 3h. The obtained composition is Sr 0.5 Ba 0.5 Nb 2 O 6 The powder is crushed and passed through a 40-mesh sieve, and the powder is mixed uniformly by wet ball milling process again; the conditions of ball milling are: ball milling material, agate ball and absolute ethanol are mixed in a mass ratio of 1:1.8:0.7, and ball milled for 48h.

[0032] Dry the obtained C...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is only: according to the general formula Ca 0.1 (Sr 0.5 Ba 0.5 ) 0.9 Nb 2 O 6 [x=0.10, abbreviated as CSBN(0.10)] Weigh the stoichiometric ratio of CaCO 3 , BaCO 3 , SrCO 3 And Nb 2 O 5 The powder.

[0038] The rest of the content of this embodiment is the same as that described in Embodiment 1.

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is only: according to the general formula Ca 0.15 (Sr 0.5 Ba 0.5 ) 0.85 Nb 2 O 6 [x=0.15, abbreviated as CSBN(0.15)] Weigh the stoichiometric ratio of CaCO 3 , BaCO 3 , SrCO 3 And Nb 2 O 5 The powder.

[0041] The rest of the content of this embodiment is the same as that described in Embodiment 1.

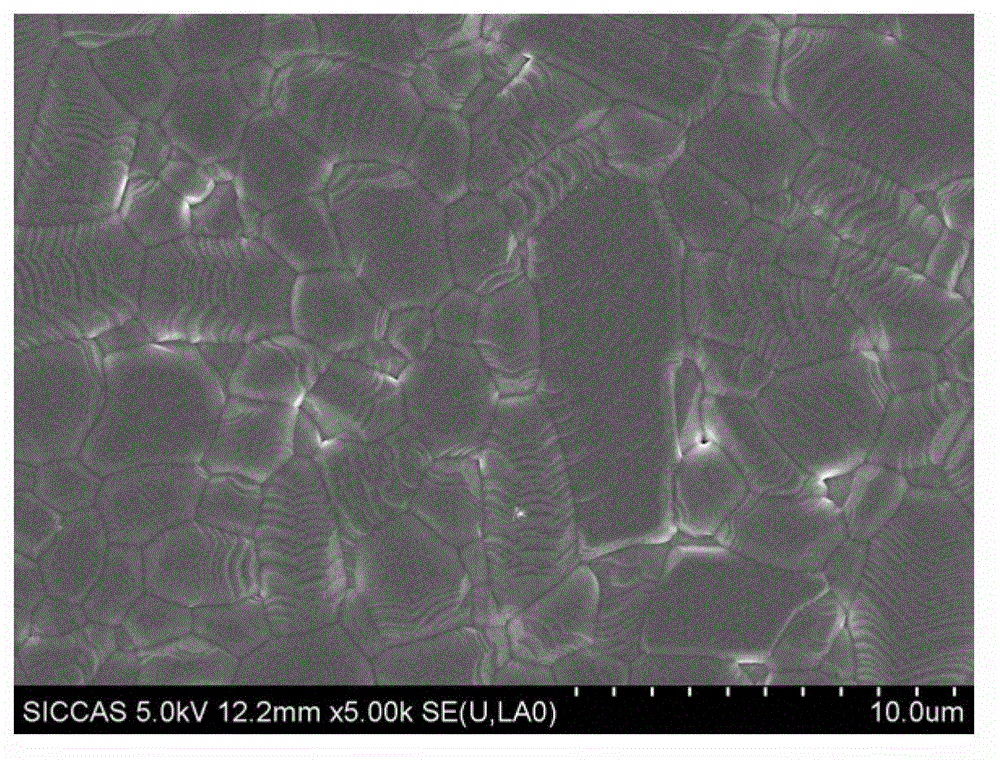

[0042] figure 1 This is a scanning electron micrograph of the strontium barium calcium niobate pyroelectric ceramic material prepared in this example after surface polishing and thermal etching. figure 1 It can be seen that most of the grain size of ceramics is small, between 1-3 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com