Microwave dielectric materials capable of burning with copper electrodes together, preparation method and application thereof

A technology of microwave dielectric materials and copper electrodes, applied in chemical instruments and methods, and other chemical processes, can solve the problems of difficult control of Zn/Ti ratio, lower density, lower density of ceramic diaphragms, etc., and achieve the temperature coefficient of resonance frequency Adjustable, moderate dielectric constant, high quality factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

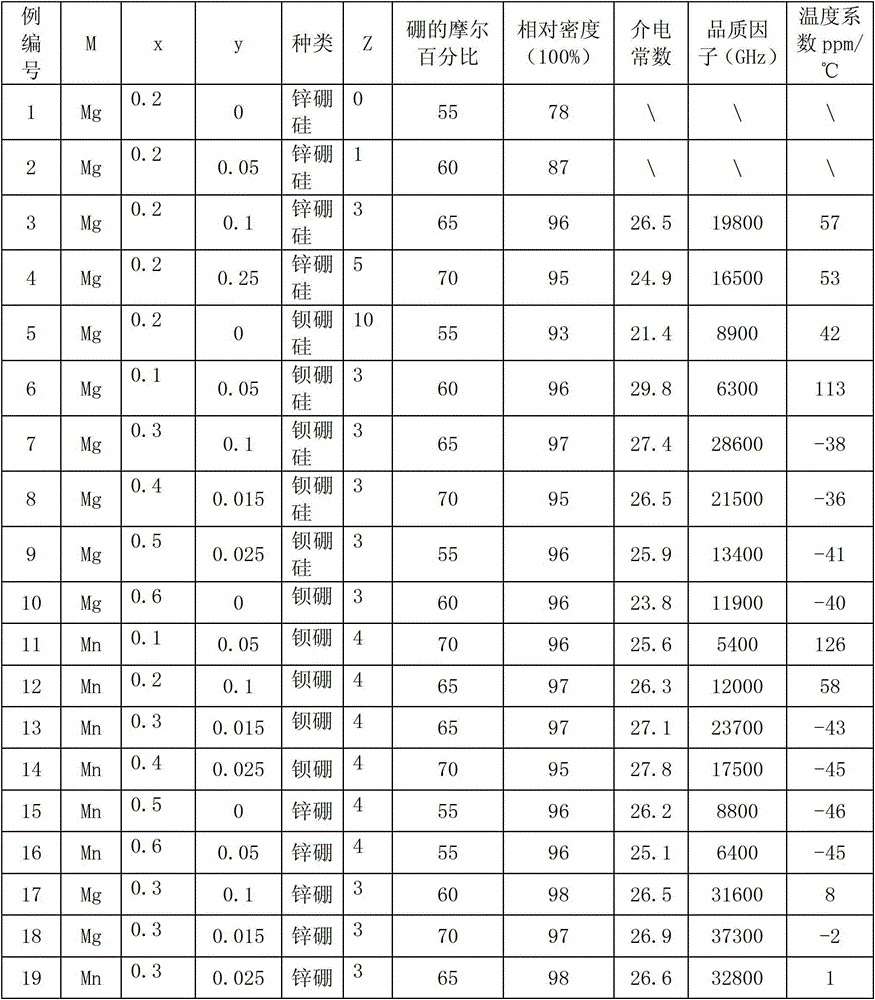

[0022] The microwave dielectric material that can be co-fired with copper electrodes of the present invention includes: (1-z)wt%[(Zn x m (1-x) )(Ti 1-y / 2 Mg y )O 3 ]+zwt% low melting point glass, wherein: M is a kind of magnesium or manganese; 0x m (1-x) )(Ti 1-y / 2 Mg y )O 3 ] The sintering temperature has a lowering effect on all low-melting glasses.

[0023] In this embodiment, the low-melting glass is barium boron glass (BaO-B 2 o 3 ), zinc boron glass (ZnO-B 2 o 3 ), barium borosilicate glass (BaO-B 2 o 3 -SiO 2 ) and zinc borosilicate glass (ZnO-B 2 o3 -SiO 2 ) or a mixture of two or more; the molar percentage of boron in the low-melting glass is 55% to 70%.

[0024] In this embodiment, the low-melting glass is zinc boron glass (ZnO-B 2 o 3 ), the zinc boron glass is composed of ZnO and H 3 BO 3 The product after the reaction; the obtained low-melting point glass powder is insoluble in water, ethanol and other solvents, and does not gel with PVA, PVB a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com