Microwave attenuation ceramic and preparation method thereof

A microwave attenuation and ceramic technology, applied in the field of wave absorbing materials, can solve the problems of low thermal conductivity, uneven distribution of attenuation phases, and obstacles to the use of high-power tubes, and achieve low elastic modulus, improved sintering density, and enhanced microwave Effect of Attenuating Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

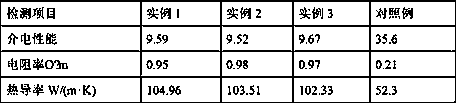

Examples

example 1

[0027] Take 150g of boric acid, add 1.2L of deionized water, stir and heat at 300r / min to 50°C, then add 300g of urea and heat up to 60°C, continue to stir for 30min and then evaporate to dryness under reduced pressure to obtain the precursor, place the precursor in In a muffle furnace, under a nitrogen atmosphere, heat up to 800°C at a rate of 20°C / min and calcinate for 3 hours, take out the product after cooling to room temperature, wash the product once with 1% hydrochloric acid, and then wash the product 1 with absolute ethanol After washing, transfer it to a drying oven and dry at 80°C for 6 hours to obtain nanosheet layered boron nitride. Take 1g of yttrium nitrate, 1g of calcium nitrate, 200g of aluminum nitrate, and 20g of glucose in 300mL of deionized water. / min and stirred for 30 minutes, then placed on a rotary evaporator and evaporated to dryness under reduced pressure to obtain a solid powder, which was placed in a muffle furnace and calcined at a rate of 20 °C / mi...

example 2

[0029] Take 180g of boric acid, add 1.3L of deionized water, stir and heat at 350r / min to 55°C, then add 350g of urea and heat up to 65°C, continue stirring for 35min and evaporate to dryness under reduced pressure to obtain a precursor, place the precursor in In a muffle furnace, under a nitrogen atmosphere, heat up to 850°C at a rate of 20°C / min and calcinate for 5 hours, take out the product after cooling to room temperature, wash the product once with 1% hydrochloric acid, and then wash the product 1 with absolute ethanol After washing, transfer it to a drying oven and dry at 85°C for 7 hours to obtain nanosheet layered boron nitride. Take 2g of yttrium nitrate, 1g of calcium nitrate, 250g of aluminum nitrate, and 30g of glucose in 400mL of deionized water. / min and stirred for 35 minutes, then placed on a rotary evaporator and evaporated to dryness under reduced pressure to obtain a solid powder, which was placed in a muffle furnace and calcined at a rate of 20 °C / min to 6...

example 3

[0031]Take 200g of boric acid, add 1.5L of deionized water, stir and heat at 400r / min to 60°C, then add 400g of urea and heat up to 70°C, continue to stir for 40min, then evaporate to dryness under reduced pressure to obtain a precursor, place the precursor in In a muffle furnace, under a nitrogen atmosphere, heat up to 900°C at a rate of 20°C / min and calcinate for 6 hours, take out the product after cooling to room temperature, wash the product twice with 1% hydrochloric acid, and then wash the product 2 with absolute ethanol After washing, transfer it to a drying oven and dry at 90°C for 8 hours to obtain nanosheet layered boron nitride. Take 3g of yttrium nitrate, 2g of calcium nitrate, 300g of aluminum nitrate, and 40g of glucose in 500mL of deionized water. / min and stirred for 40 minutes, then placed on a rotary evaporator and evaporated to dryness under reduced pressure to obtain a solid powder, which was placed in a muffle furnace and calcined at a rate of 20 °C / min to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com