Iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent and preparation method thereof

A technology of iron-based nanocrystals and soft magnetic alloys, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve problems such as low equipment requirements, complex processes, and poor particle size uniformity of powders, and achieve saturation magnetization and magnetic High conductivity, excellent high-frequency absorbing performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing an iron-based nanocrystalline soft magnetic alloy powder electromagnetic wave absorber. The preparation of the alloy powder includes the following steps:

[0043] Step 1: preparation of raw materials for preparing alloy micropowder;

[0044] Step 2: preparation of nanocrystalline alloy powder;

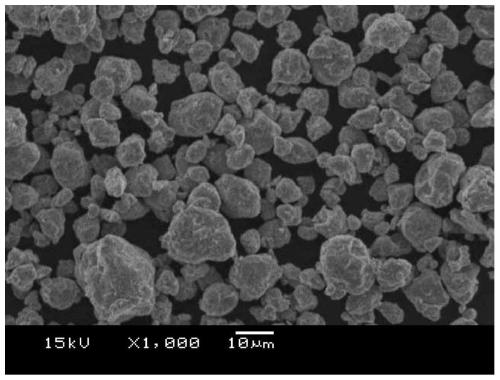

[0045] The raw materials for preparing alloy micropowder with a diameter of less than 300 μm are selected and put into a ball mill tank, vacuumized and then filled with inert gas for protection, and ball milled to obtain alloy micropowder.

[0046] Further, the preparation process of step 1 includes: weighing the powder raw materials of each component to prepare an alloy according to the nominal composition of the alloy powder, and melting each component in an inert gas atmosphere by using an induction melting furnace or a non-consumable electric arc furnace The powder raw material is obtained to obtain a chemically uni...

Embodiment 1

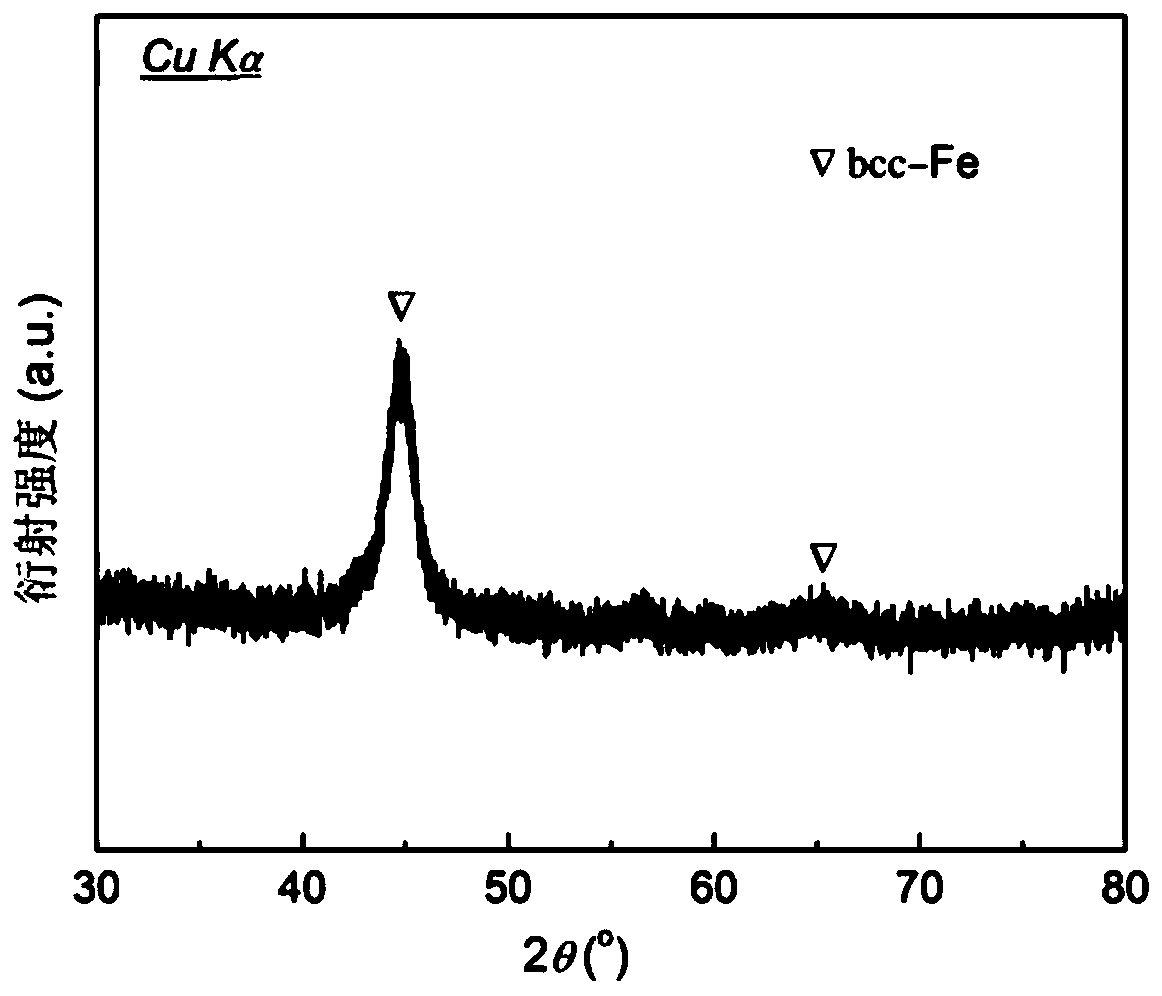

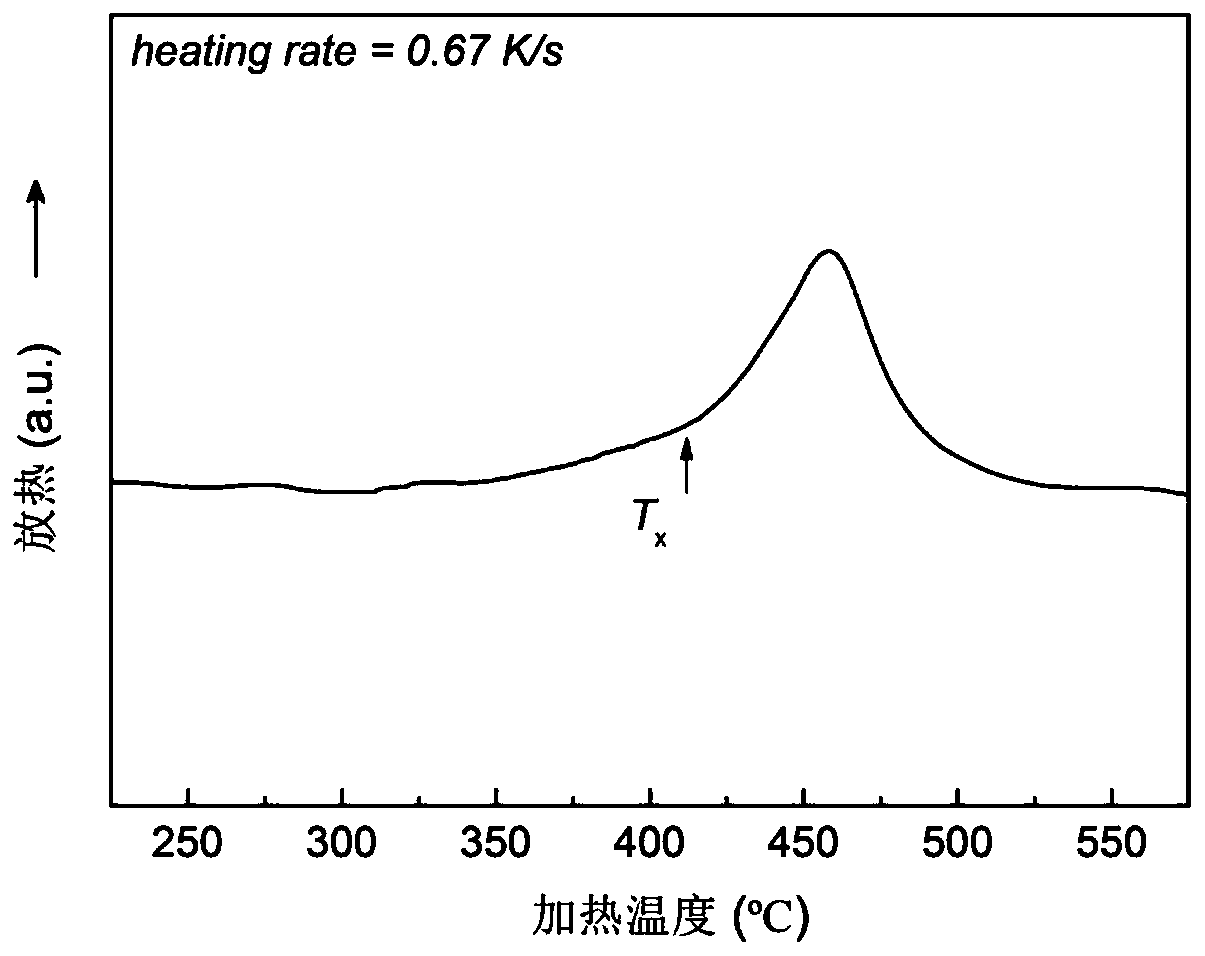

[0053] Fe 80.7 Si 4 B 13 Cu 2.3

[0054] (1) Preparation of as-cast master alloy ingot

[0055] Fe, Si, B and Cu raw materials with a purity of not less than 99% (mass percentage) are weighed and proportioned according to the nominal composition of the alloy, and the alloy raw materials are repeatedly smelted three times in an argon atmosphere in a non-consumable electric arc furnace to obtain Master alloy ingot with uniform composition.

[0056] (2) Preparation of nanocrystalline alloy powder

[0057] The master alloy ingot is mechanically pre-crushed and passed through a 60-mesh sieve, and the alloy powder with a particle size of less than 300 μm is put into a ball mill. -3 Pa, filled with argon gas as a protective gas, put it into a planetary ball mill for ball milling after sealing, control the speed of the ball mill to 350rpm, stop for 5 minutes for cooling every 30min, and set the ball milling time to 40h, 80h, 120h respectively to reach the set ball milling time ...

Embodiment 2

[0069] Fe 89 Si7 B 3 Cu 1

[0070] (1) Preparation of as-cast master alloy ingot

[0071] This step is with embodiment 1.

[0072] (2) Preparation of nanocrystalline alloy powder

[0073] This step is with embodiment 1. The difference between this embodiment and embodiment 1 is that the ball milling time is set to 60h and 90h respectively, and no heat treatment is required.

[0074] (3) Structural characterization, morphology observation and performance testing of iron-based nanocrystalline alloy electromagnetic wave absorbers

[0075] This step is with embodiment 1.

[0076] The alloy powders obtained after ball milling for different times all have nanocrystalline / amorphous mixed structure, and the grain size of the bcc-Fe phase is about 12nm; The micropowder has typical soft magnetic properties, and the saturation magnetization is in the range of 192.6-196.0emu / g; the μ' of the alloy micropowder / paraffin composite sample is 2.25-2.40 at 2GHz, and the maximum value of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com