Microwave ceramic SrO-ZnO(MgO)-TiO2 and preparation method thereof

A kind of microwave ceramics, 0 high sintering temperature and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

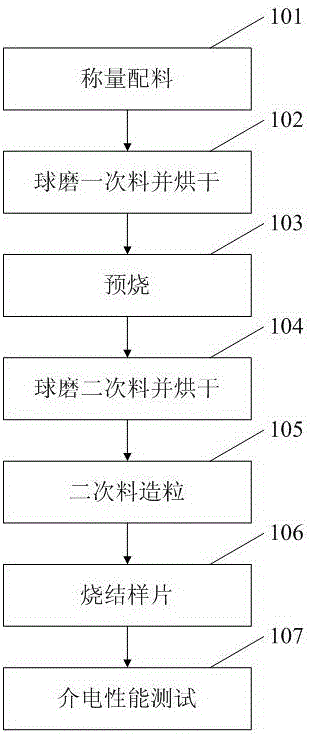

Method used

Image

Examples

Embodiment 1

[0041] The microwave ceramic SrO-ZnO(MgO)-TiO 2 The chemical expression is 0.9[SrO-(Zn 0.1 Mg 0.9 )O]-0.1TiO 2 , its preparation method is:

[0042] Preparation of Microwave Ceramics SrO-ZnO(MgO)-TiO Using the Raw Materials and Sintering Aids Above 2 method, the method is carried out as follows:

[0043] Step 1, high-purity SrO, ZnO, MgO and TiO 2 According to SrO:ZnO:MgO:TiO 2 =0.9:0.09:0.81:0.1 molar ratio proportioning takes raw materials;

[0044] Step 2, put the raw materials in step 1 into a planetary ball mill, add deionized water and zirconia balls, ball mill for 8 hours, and then dry the ball milled raw materials in an electric blast drying oven at 110°C. The dried powder is passed through a 50-mesh sieve to obtain powder with uniform particles;

[0045] Step 3, heating the powder treated in step 2 to 1000°C and keeping it warm for 2 hours to obtain the pre-fired material;

[0046] Step 4, the calcined material processed through step 3 is put into the ball mi...

Embodiment 2

[0050] The microwave ceramic SrO-ZnO(MgO)-TiO 2 The chemical expression is 0.8[SrO-(Zn 0.9 Mg 0.1 )O]-0.2TiO 2 , its preparation method is:

[0051] Preparation of Microwave Ceramics SrO-ZnO(MgO)-TiO Using the Raw Materials and Sintering Aids Above 2 method, the method is carried out as follows:

[0052] Step 1, high-purity SrO, ZnO, MgO and TiO 2 According to SrO:ZnO:MgO:TiO 2 =0.8:0.72:0.08:0.2 molar ratio proportioning takes raw materials;

[0053] Step 2, put the raw materials in step 1 into a planetary ball mill, add deionized water and zirconia balls, ball mill for 2 hours, and then dry the ball milled raw materials in an electric blast drying oven at 110°C, The dried powder is passed through a 50-mesh sieve to obtain powder with uniform particles;

[0054] Step 3, heating the powder treated in step 2 to 1100°C and keeping it warm for 8 hours to obtain pre-burned material;

[0055] Step 4, the calcined material processed through step 3 is put into the ball mill,...

Embodiment 3

[0059] The microwave ceramic SrO-ZnO(MgO)-TiO 2 The chemical expression is 0.86[SrO-(Zn 0.5 Mg 0.5 )O]-0.14TiO 2 , its preparation method is:

[0060] Preparation of Microwave Ceramics SrO-ZnO(MgO)-TiO Using the Raw Materials and Sintering Aids Above 2 method, the method is carried out as follows:

[0061] Step 1, high-purity SrO, ZnO, MgO and TiO 2 According to SrO:ZnO:MgO:TiO 2 =0.86:0.43:0.43:0.14 molar ratio proportioning takes raw materials;

[0062] Step 2, put the raw materials in step 1 into a planetary ball mill, add deionized water and zirconia balls, ball mill for 4 hours, and then dry the ball milled raw materials in an electric blast drying oven at 110°C. The dried powder is passed through a 50-mesh sieve to obtain powder with uniform particles;

[0063] Step 3, heating the powder treated in step 2 to 1050°C and keeping it warm for 4 hours to obtain pre-burned material;

[0064] Step 4, the calcined material processed through step 3 is put into the ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric properties | aaaaa | aaaaa |

| dielectric properties | aaaaa | aaaaa |

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com