Preparation method of lead scandium tantalate pyroelectric ceramics

A technology of pyroelectric ceramics and lead tantalum scandate, which is applied in the field of preparation of lead tantalum scandate pyroelectric ceramics, can solve the problems of deterioration of electrical properties of samples and insufficient compensation for PbO loss, etc. The effect of large electric coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Pb(Sc 0.5 Ta 0.5 )O 3 Powder. First according to ScTaO 4 The stoichiometric ratio of Sc 2 o 3 Powder (analytical pure) and Ta 2 o 5 Powder (analytically pure), add 0.8 times of the total weight of raw materials in deionized water, and mix by wet ball milling for 24 hours, so that all components are mixed evenly. Dry it, add 10wt% deionized water, and keep the briquette at 1350° C. for 4 hours to synthesize it. Crush and pass through a 40-mesh sieve.

[0027] Then PbO and ScTaO 4 Weigh and add excess 2.5wt% PbO according to stoichiometric ratio, and mix for 24 hours by wet ball milling. After drying, the briquette was synthesized at 1150°C in the atmosphere, and kept for 2 hours to obtain Pb(Sc 0.5 Ta 0.5 )O 3 Solid solution powder. Then finely grind for 24 hours by wet ball milling method, dry the powder, add 5wt% PVA binder, granulate, age for 24 hours, pass through a 20-mesh sieve, press and mold, and discharge the plastic at 800°C. The sample was hot-p...

Embodiment 2

[0029] In Pb(Sc 0.5 Ta 0.5 )O 3 Add excessive 5wt% PbO in the mixture, repeat the preparation method of Example 1 according to the above formula, and the test results are listed in Table 1.

Embodiment 3

[0031] In Pb(Sc 0.5 Ta 0.5 )O 3 Add an excess of 7.5wt% PbO, repeat the preparation method of Example 1 according to the above formula, and test results are listed in Table 1.

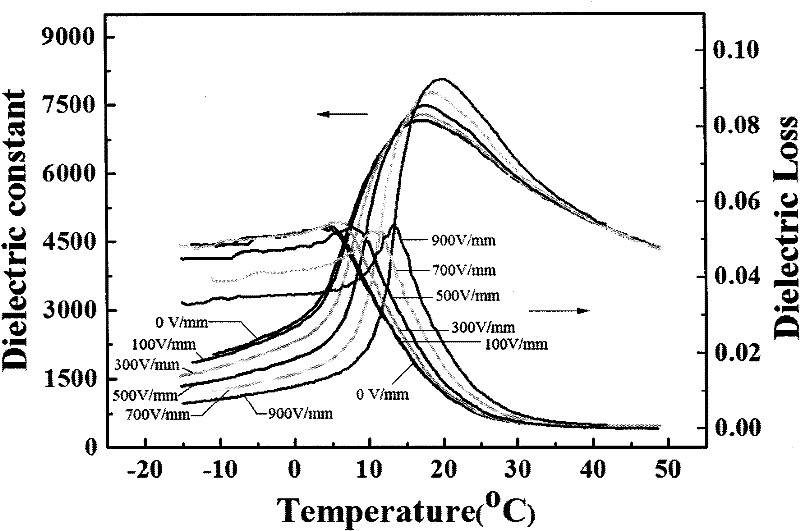

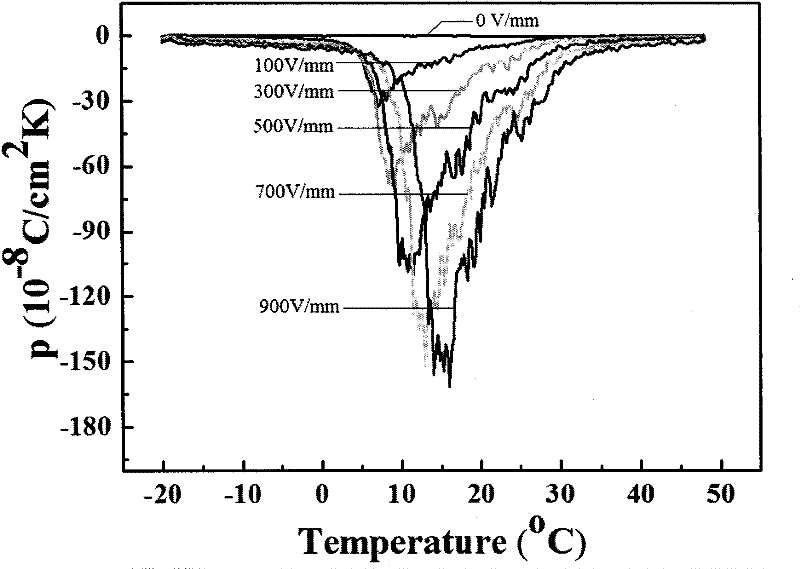

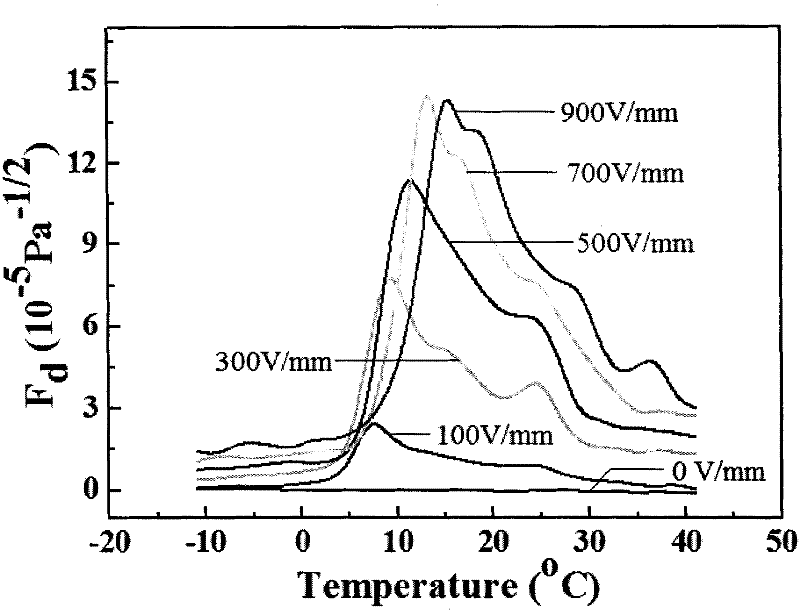

[0032] The main properties (room temperature) of table 1 embodiment material under 900V / mm bias

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com