Microwave-tuned composite ceramic material and preparation method thereof

A composite ceramic and microwave technology, which is applied in the field of microwave ceramic materials, can solve the problems of high dielectric constant of barium zirconate titanate, high microwave dielectric loss, and difficult circuit matching, and achieves non-toxic side effects, environmental protection and side effects, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-5

[0021] powdered BaCO 3 , ZrO 2 、TiO 2 , SiO 2 and MgO as raw materials, respectively prepare BaZr according to the stoichiometric ratio x Ti 1-x o 3 (x=0.2) and Mg 2 SiO 4 , adding absolute ethanol or deionized water to the raw material, using agate balls or zirconia as the ball milling medium, after wet ball milling for 6 hours, discharging, drying, and pre-calcining the powder at 1100°C for 2 hours to obtain BaZr x Ti 1-x o 3 (x=0.2) and Mg 2 SiO 4 Powder. According to the formula in Table 1, the BaZr x Ti 1-x o 3 (x=0.2), Mg 2 SiO 4 Mix with MgO, wet ball mill for 6 hours, discharge and dry, use 5wt% polyvinyl alcohol as a binder to granulate, and press the powder under a pressure of 150MPa; Sintered at 1320°C for 3h in the atmosphere to obtain BaZr 0.2 Ti 0.8 o 3 -MgO-Mg 2 SiO 4 Composite ceramics. The fired samples are finely ground, ultrasonically cleaned, and then silver electrodes are applied, which can be used for dielectric property testing.

...

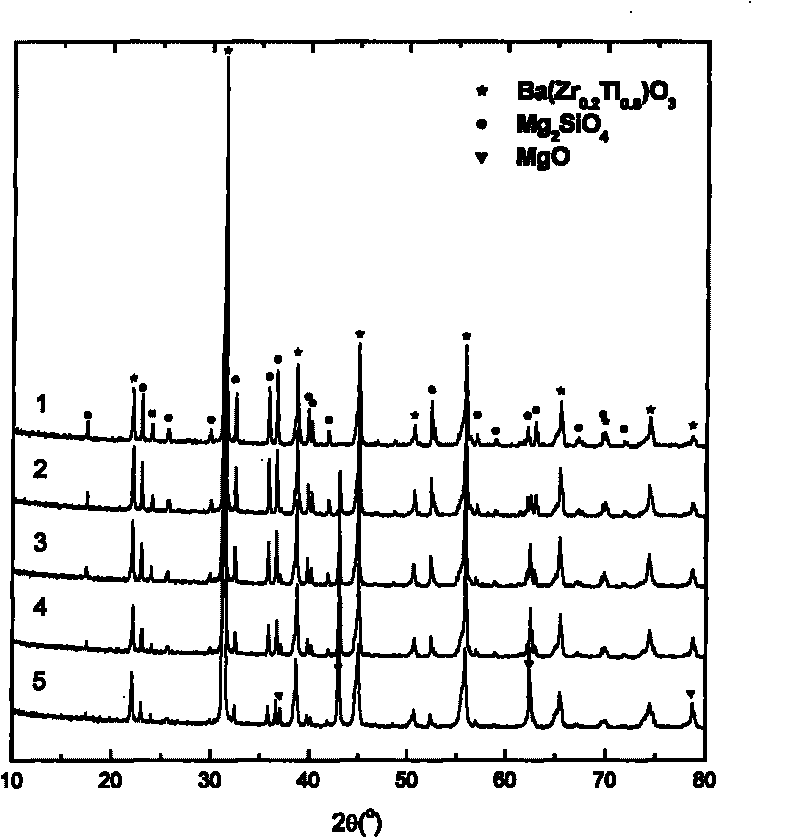

Embodiment 1

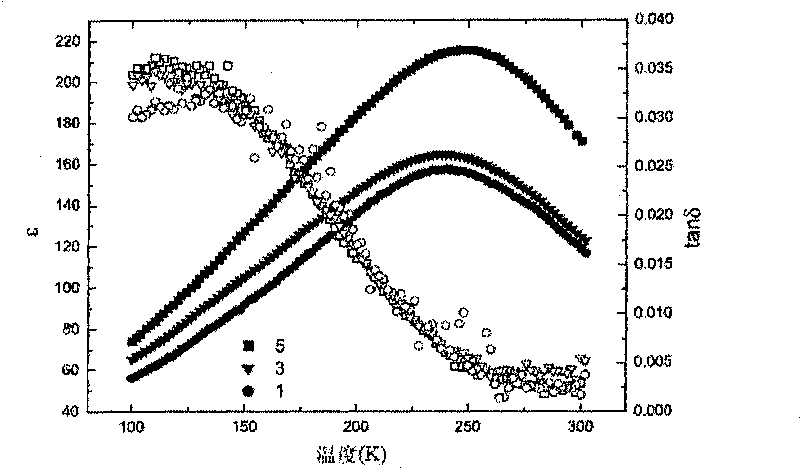

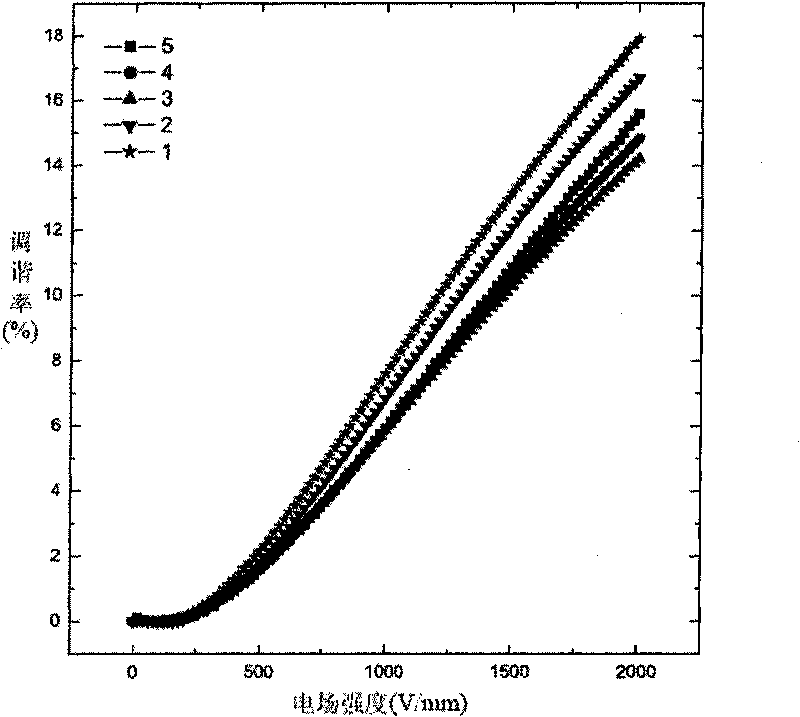

[0027] The BaZr that embodiment 1-5 formula gains x Ti 1-x o 3 -MgO-Mg 2 SiO 4 XRD spectrum of composite ceramics. Composite ceramic materials made of BaZr x Ti 1-x o 3 (x=0.2), MgO and Mg 2SiO 4 Three-phase composition. Embodiment 1,3, the BaZr that 5 formulas gain x Ti 1-x o 3 -MgO-Mg 2 SiO 4 The relationship between dielectric constant and dielectric loss of composite ceramics and temperature is as follows: figure 2 shown. The BaZr that embodiment 1-5 formula gains x Ti 1-x o 3 -MgO-Mg 2 SiO 4 The tuning rate of composite ceramics under different DC electric field strengths is as follows: image 3 shown. Reduced MgO content, BaZr x Ti 1-x o 3 -MgO-Mg 2 SiO 4 The dielectric constant of composite ceramics decreases, but Mg 2 SiO 4 The tuning rate increases when the content exceeds 30wt%. This provides a way to lower the dielectric constant of the material while increasing the tuning rate of the material. In the prior art, the reduction of the d...

example 6

[0028] Example 6: x=0.1, BaZr x Ti 1-x o 3 The mass percentage is 30%, Mg 2 SiO 4 The mass percent content in the mixture is 1%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com